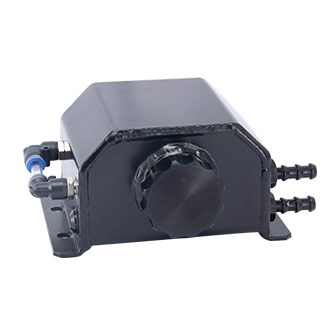

automotive oil cooler

An automotive oil cooler is a vital component in modern vehicle systems, designed to regulate and maintain optimal engine oil temperature during operation. This specialized heat exchanger works by circulating hot engine oil through a series of tubes or plates surrounded by a cooling medium, typically air or coolant. The primary function of an automotive oil cooler is to prevent oil degradation and ensure consistent engine performance by keeping oil temperatures within ideal operating ranges. The system employs advanced thermal management technology, utilizing either air-cooled or liquid-cooled designs depending on the specific application and vehicle requirements. In air-cooled systems, the oil cooler is typically mounted in front of the radiator, allowing ambient air to reduce oil temperature as the vehicle moves. Liquid-cooled variants integrate with the engine's cooling system, offering more efficient heat transfer in high-performance applications. Modern automotive oil coolers feature durable construction materials, including aluminum cores and robust fittings, ensuring longevity and reliable performance under demanding conditions. These units are essential for vehicles subjected to heavy loads, towing operations, or high-performance driving, where engine oil temperatures can rise significantly above normal operating levels.