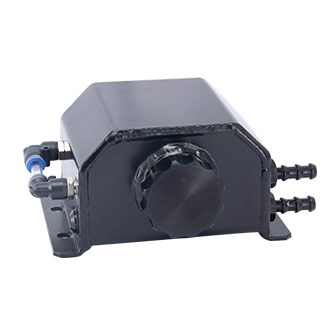

radiator and oil cooler

The radiator and oil cooler system represents a crucial component in modern machinery and vehicles, serving as an integrated thermal management solution. This sophisticated system combines two essential functions: managing engine temperature through the radiator and maintaining optimal oil temperature via the oil cooler. The radiator works by circulating coolant through a series of tubes and fins, effectively dissipating heat generated by the engine into the surrounding air. Meanwhile, the oil cooler ensures that the engine oil maintains its viscosity and lubricating properties by preventing it from becoming too hot during operation. This dual-function system employs advanced heat exchange technology, utilizing cross-flow or parallel-flow designs to maximize thermal efficiency. The components are typically constructed from high-grade aluminum or copper materials, offering excellent heat transfer properties while remaining lightweight and durable. Modern designs incorporate multiple pass systems and turbulators to enhance cooling performance and optimize fluid flow dynamics. These systems are essential in various applications, from automotive and industrial machinery to power generation equipment, where maintaining optimal operating temperatures is critical for performance and longevity.