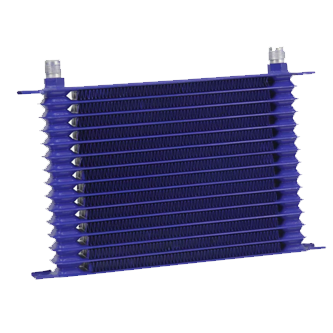

universal oil cooler

A universal oil cooler is an essential component designed to regulate and maintain optimal oil temperature in various mechanical systems. This versatile heat exchanger effectively transfers excess heat from oil to either air or coolant, preventing system overheating and ensuring optimal performance. The device consists of a series of tubes or plates through which oil flows, surrounded by cooling medium channels that facilitate efficient heat dissipation. Advanced universal oil coolers incorporate innovative fin designs and premium materials like aluminum or stainless steel, maximizing thermal conductivity while minimizing size and weight. These units are engineered to withstand high pressures and temperatures, featuring robust construction that ensures longevity and reliable performance. The universal design allows for compatibility with numerous applications, including automotive engines, industrial machinery, hydraulic systems, and transmission units. Modern oil coolers often include additional features such as integrated thermostats, bypass valves, and mounting brackets for enhanced functionality and ease of installation. Their adaptable nature makes them suitable for both OEM applications and aftermarket upgrades, providing a cost-effective solution for temperature management across diverse operating conditions.