coolers for motorcycles

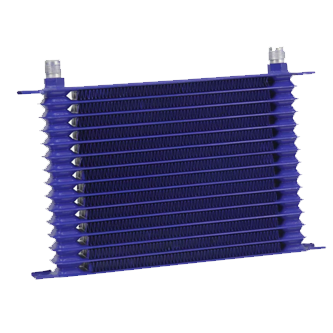

Motorcycle coolers are essential components designed to maintain optimal operating temperatures for motorcycles, ensuring peak performance and longevity of the engine. These sophisticated cooling systems incorporate advanced heat exchange technology, utilizing a combination of coolant circulation and efficient radiator designs to regulate engine temperature effectively. Modern motorcycle coolers feature compact yet powerful configurations that maximize cooling capacity while minimizing space requirements. The systems typically include precision-engineered cooling fins, high-grade aluminum construction, and optimized coolant flow patterns to enhance heat dissipation. These coolers are particularly crucial for high-performance motorcycles and those operating in demanding conditions, where maintaining stable engine temperatures is essential for preventing overheating and ensuring consistent performance. The technology behind motorcycle coolers has evolved significantly, now incorporating smart sensors and automated cooling management systems that adjust cooling intensity based on real-time engine temperature and operating conditions. Additionally, many contemporary models feature integrated overflow reservoirs and pressure-relief mechanisms to maintain optimal coolant levels and prevent system damage from excessive pressure buildup.