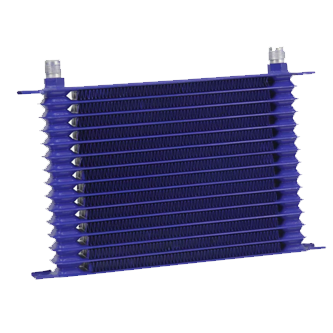

cooler engine

A cooler engine represents a revolutionary advancement in thermal management technology, designed to maintain optimal operating temperatures in various mechanical systems. This innovative cooling solution combines advanced heat exchange principles with sophisticated control mechanisms to deliver superior temperature regulation. The system utilizes a network of carefully engineered components, including heat exchangers, coolant circulation systems, and smart temperature sensors, working in harmony to ensure consistent and efficient cooling performance. The primary function involves extracting excess heat from critical components and dissipating it effectively into the surrounding environment. Applications span across multiple industries, from automotive and industrial machinery to power generation and HVAC systems. The cooler engine employs cutting-edge thermal dynamics to achieve maximum efficiency while minimizing energy consumption. Its modular design allows for easy integration into existing systems, while its adaptive control algorithms continuously optimize cooling parameters based on real-time operational demands. The technology incorporates advanced materials and precise engineering tolerances to ensure durability and reliability under various operating conditions. This versatile solution addresses the growing need for efficient cooling in increasingly powerful and compact mechanical systems, making it an essential component in modern engineering applications.