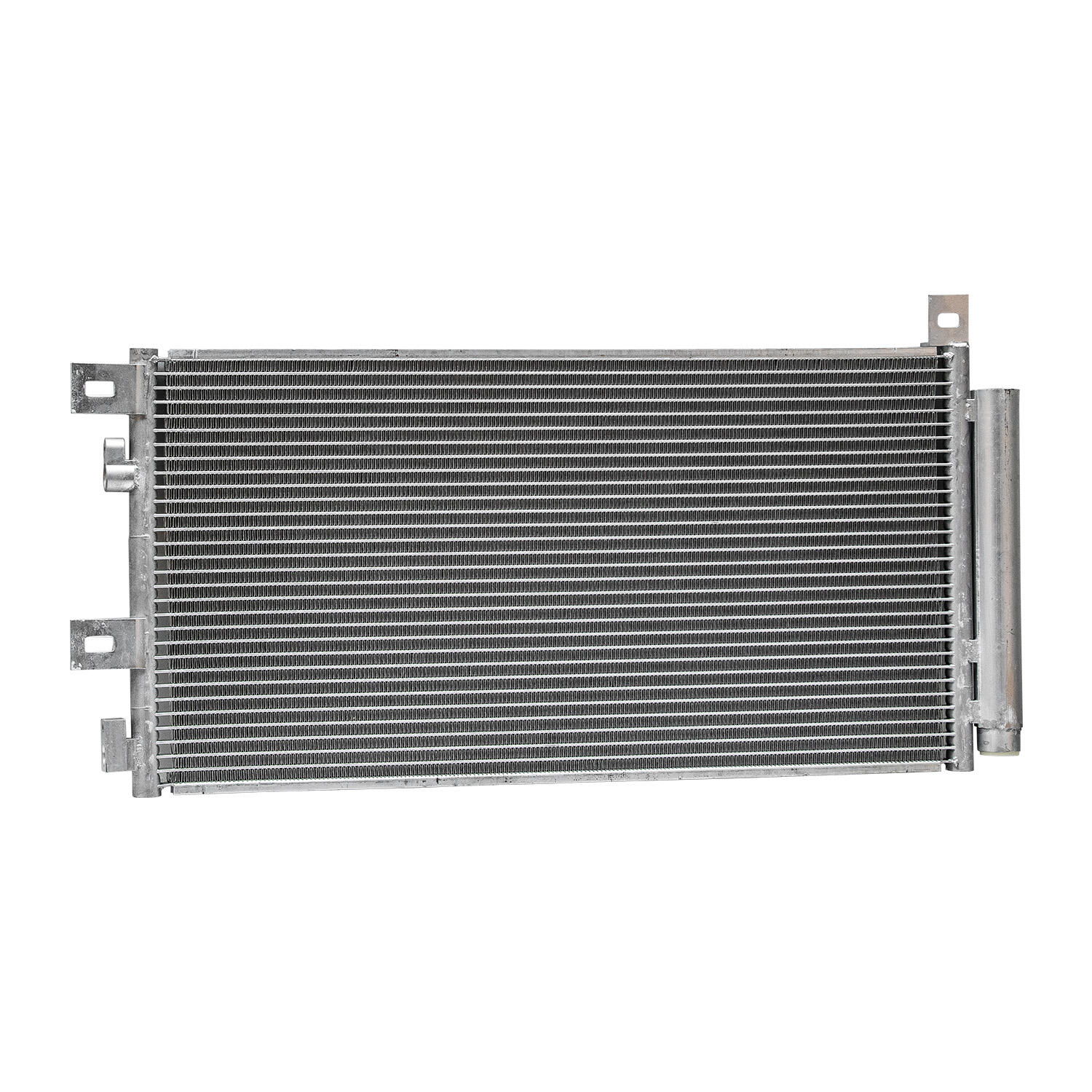

2.5 အလူမီနီယမ် intercooler piping

၂.၅ အင်္ဂါလီမန် အင်တာကိုးလာပိုင်းသည် စီးရီးအောက်ပိုင်း ဖြင့်ထုတ်လုပ်ထားသော စနစ်များတွင် အခြေခံအစိတ်အပိုင်းတစ်ခုဖြစ်ပြီး၊ လေစီးခြင်းကို အကောင်အထည်ဖော်ရန်နှင့် အင်ဂျင်၏ အလုပ်ဆောင်မှုကို တိုးတက်စေရန် ဒီဇိုင်းထုတ်ထားသည်။ ဒီ ပိုင်းသည် ၂.၅ အင်ဗီယာတွင် အရှိန်တိုးတက်မှုကို တိုးတက်စေရန် တီထွင်ထုတ်လုပ်ထားသော ပိုင်းကို တူရှိုင်းသို့不然် supercharger နှင့် အင်တာကိုးလာအကြားတွင် အဓိကအချက်တစ်ခုအဖြစ် ဆောင်ရွက်ပြီး၊ လေကို ကြီးမားစွာ ပေးဆောင်ရန်နှင့် အပူချိန်ကို ကြီးမားစွာ လုပ်ဆောင်ရန် ကူညီပါသည်။ အမြင်သို့မဟုတ် အင်္ဂါလီမန်အများဆုံးအဆင့်တွင် ထုတ်လုပ်ထားသော ဒီပိုင်းများသည် အခြေခံအားနှင့် လျှော့ချထားသော ဖျားဖြင့် ပြောင်းလဲမှုကို ပြောင်းလဲနိုင်စေရန် အဆင့်အတန်းကို ပြောင်းလဲနိုင်စေပါသည်။ အင်္ဂါလီမန်ဖြင့် တည်ဆောက်ထားသော ဒီပိုင်းများသည် ပုံမှန်ဝcroft်းကို အကောင်အထည်ဖော်ထားသော ပစ္စည်းများနှင့် နှိုင်းယှဉ်ပြီး အပူချိန်ကို ပိုမိုကောင်းမွန်စွာ ဖယ်ရှားနိုင်ပြီး၊ ၂.၅-အင်ဗီယာအချိန်သည် အများစုပြင်ဆင်ထားသော အင်ဂျင်များအတွက် အကောင်အထည်ဖော်သော လေစီးခြင်းအချိန်များကို ပေးဆောင်နိုင်ပါသည်။ ပိုင်းများသည် မိန်းဒ်ရှ်ဘင်ထုတ်လုပ်မှုဖြင့် အချိန်အတွင်းတွင် အတိုင်းအတာကို ထိန်းသိမ်းရန် ကြိုးပမ်းထားပြီး၊ လေစီးခြင်းကို ကန့်သတ်မှုများနှင့် လေစီးခြင်းကို လျှော့ချနိုင်စေပါသည်။ ရှေ့ဆုံးပြင်ဆင်မှုနည်းပညာများဖြင့် လောင်းအတွင်းမှာ လျှော့ချထားသော အင်တာဗောင်များကို ဖျက်ရှားပြီး စနစ်အလုပ်ဆောင်မှုကို တိုးတက်စေပါသည်။ ပိုင်းခြားတစ်ခုချင်းတွင် အကောင်အထည်ဖော်မှုများကို တိုက်ရိုက်စစ်ဆေးပြီး ပိတ်ဆိုင်မှုနှင့် အခြေအနေများကို ထိန်းသိမ်းရန် အခြားအချက်များကို ထိန်းသိမ်းရန် အရောင်းအကြားဖြစ်သည်။