hringur með legu

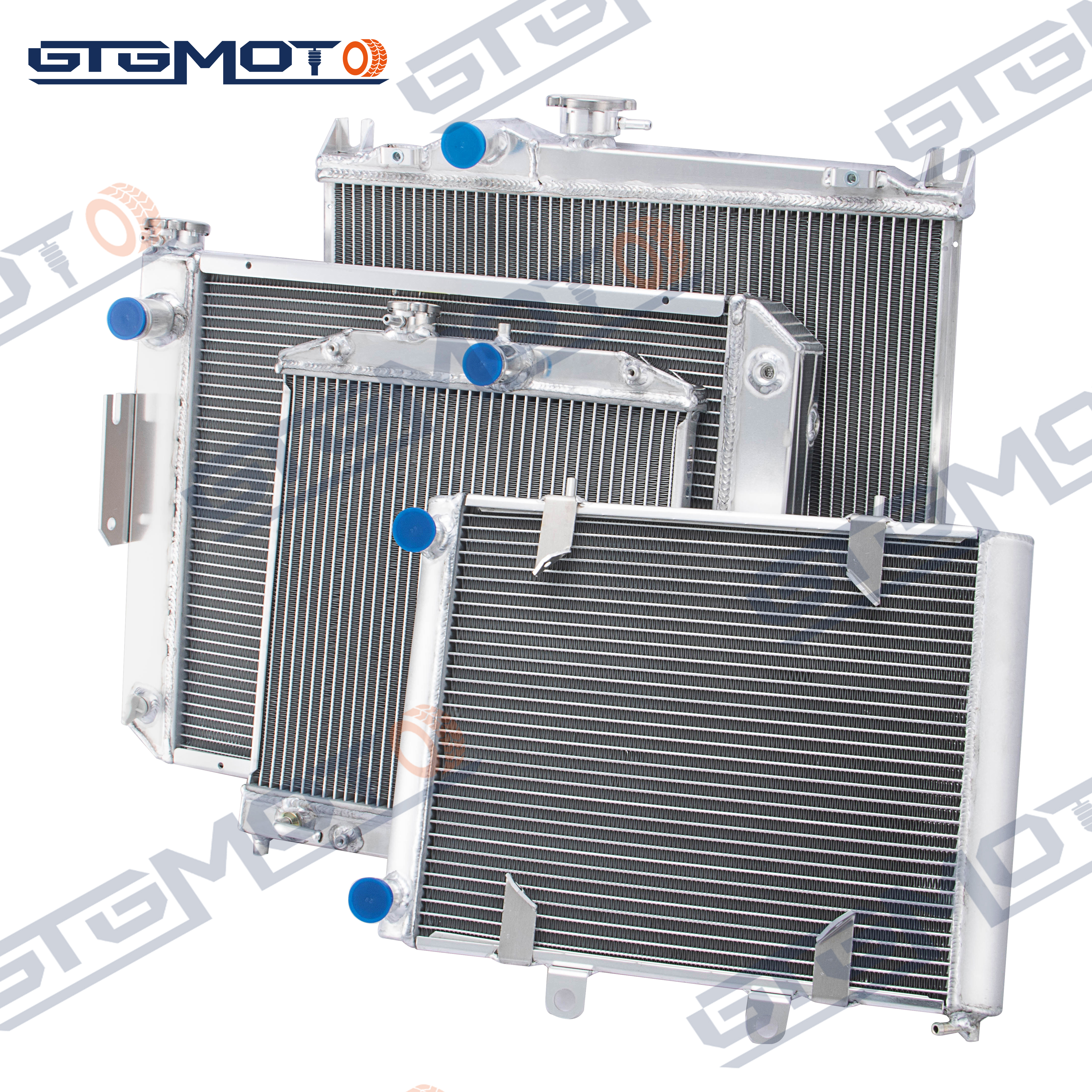

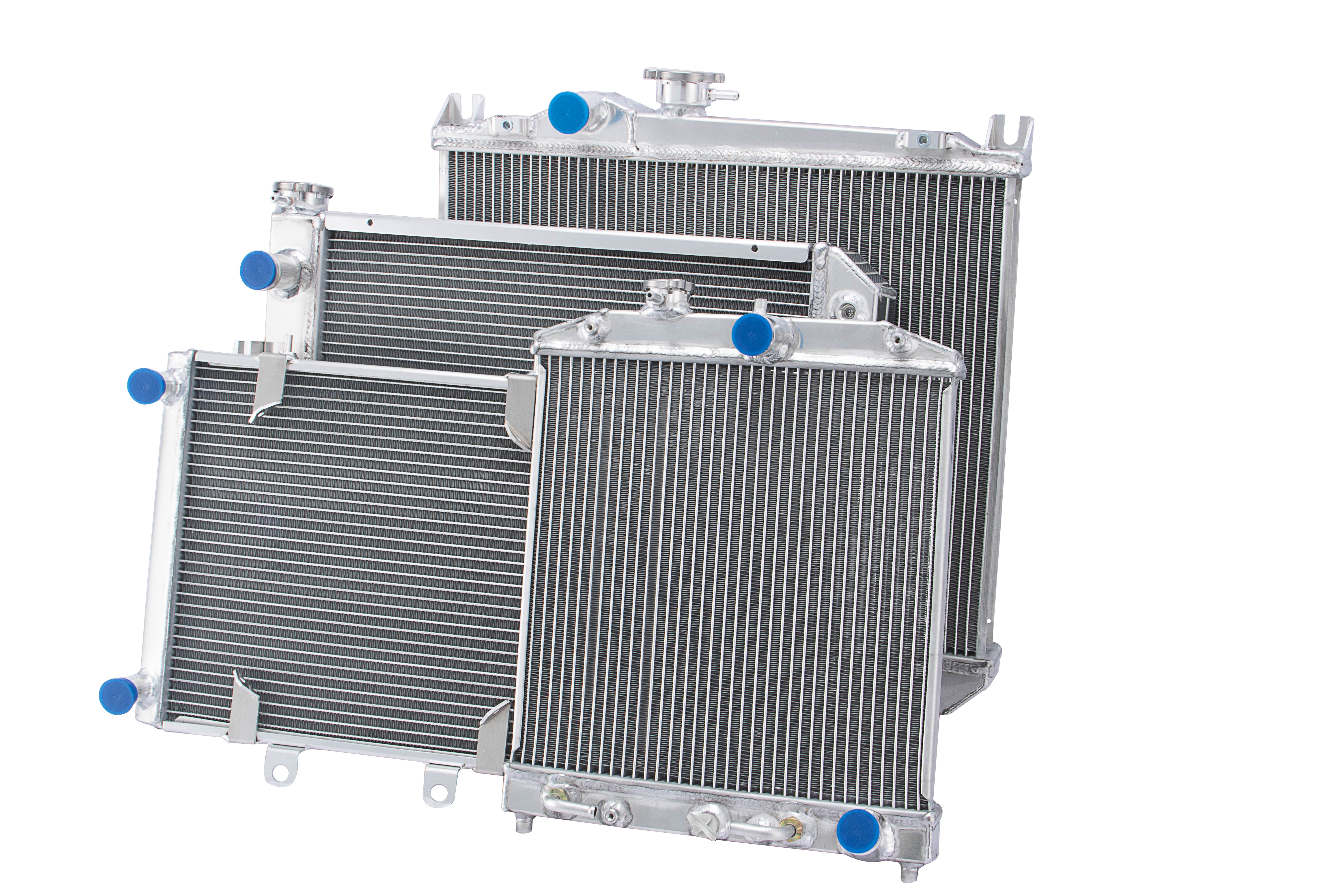

Stýri með hringi hefur verið að koma fyrir sem erfitt verkætla sem samanvistar virkni hvelstýrsins og nákvæma hringja í eina, sameinuð einingu. Þessi háþjóðslega verkætla er viðbótarsamhengurinn milli stöðvarkerfi bilsins og hvelinum, sem gerir kleifandi snúning mögulega meðan hún stuttir mikilvægar radíala og áxlalastir. Hún inniheldur frumvarpargerðunaraðferðir, með nákvæmlega skorið yfirborð, bestuðu hringageometrú og hágráðu efni sem tryggja styrkt og framkvæmd. Nútímahvelstýrir með hringum innihalda oft samskiptu síumar fyrir ólátarbræðslukerfi og trækstjórnun, sem bæta tryggingu og framkvæmdargervi bílsins. Samsetningin er sérstaklega ræst til að halda rétt hveljöfnun, lækkja fjárleika og gefa samfelld, trúfæra virkni í mismunandi keyrisskilyrðum. Þessar einingar eru gerðar með nákvæmum þvermál og fara gegnum streng justagreiningarferli til að tryggja bestu framkvæmd og langtíma. Sameinun margra hluta í eina einingu minnkur markvistlega vandnað við uppsetningu, viðhaldsforsendur og mögulegar tólastöðvar, gerðu því til athyglið kerpi í nútímaskeiðgerð.