Fleet managers face critical decisions when sourcing automotive components, particularly when it comes to air conditioning systems. The ac condenser represents one of the most essential components in vehicle climate control, directly impacting driver comfort, operational efficiency, and overall fleet performance. Understanding the key criteria for selecting the right ac condenser can significantly reduce maintenance costs, minimize downtime, and ensure optimal vehicle performance across diverse operating conditions.

Modern fleet operations demand reliable cooling systems that can withstand extensive use, varying environmental conditions, and demanding schedules. An effective ac condenser sourcing strategy requires careful evaluation of multiple factors, from material composition to manufacturer reputation. This comprehensive approach ensures that fleet operators make informed decisions that balance initial investment with long-term operational benefits.

Material Quality and Construction Standards

Aluminum versus Copper Construction

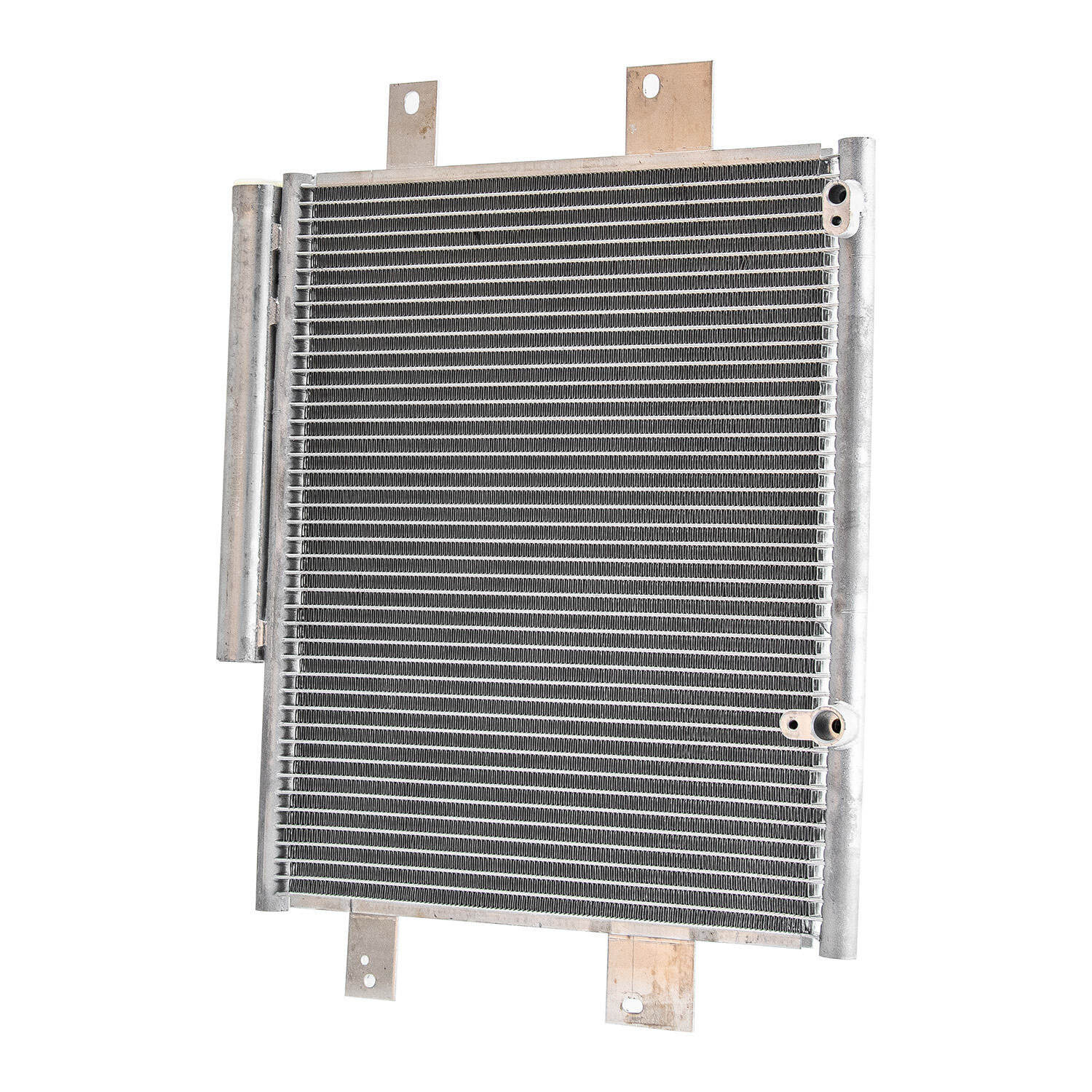

The choice between aluminum and copper construction significantly impacts ac condenser performance and longevity. Aluminum condensers offer superior corrosion resistance, lighter weight, and improved heat transfer efficiency compared to traditional copper units. These advantages translate into reduced fuel consumption due to lower vehicle weight and enhanced cooling performance under demanding conditions.

Fleet buyers should prioritize aluminum construction when operating in coastal areas or regions with high humidity levels. The corrosion resistance of aluminum extends component lifespan, reducing replacement frequency and associated labor costs. Additionally, aluminum ac condenser units typically feature enhanced fin designs that maximize surface area for improved heat dissipation.

Manufacturing Tolerances and Quality Control

Precise manufacturing tolerances ensure proper fitment and optimal performance in fleet vehicles. Quality ac condenser units undergo rigorous testing procedures, including pressure testing, leak detection, and thermal cycling evaluation. These quality control measures verify that each unit meets industry standards for durability and performance consistency.

Fleet managers should verify that potential suppliers maintain ISO certification and implement comprehensive quality management systems. Documentation of manufacturing processes, testing procedures, and quality metrics provides transparency and confidence in component reliability. This attention to manufacturing standards directly correlates with reduced warranty claims and improved field performance.

Performance Specifications and Compatibility

Cooling Capacity and Efficiency Ratings

Accurate cooling capacity specifications ensure that the selected ac condenser meets the thermal demands of specific vehicle models and operating conditions. Fleet buyers must evaluate BTU ratings, refrigerant flow characteristics, and temperature differential capabilities to match component performance with application requirements.

Efficiency ratings provide insight into energy consumption and impact on vehicle fuel economy. High-efficiency ac condenser designs minimize compressor load, reducing engine strain and improving overall vehicle performance. This efficiency consideration becomes particularly important for fleets operating in extreme climates or under continuous duty cycles.

OEM Specifications and Aftermarket Compatibility

Maintaining compatibility with original equipment specifications ensures seamless integration and optimal performance. Fleet buyers should verify that aftermarket ac condenser units meet or exceed OEM dimensional tolerances, mounting configurations, and refrigerant capacity requirements.

Compatibility extends beyond physical dimensions to include refrigerant type compatibility, pressure ratings, and electrical connections where applicable. Modern ac condenser systems may incorporate sensors or electronic components that require specific compatibility considerations for proper vehicle integration and diagnostic capability.

Supplier Evaluation and Vendor Selection

Manufacturing Capabilities and Production Scale

Supplier evaluation should encompass manufacturing capabilities, production capacity, and ability to meet fleet-specific requirements. Large-scale fleet operations require suppliers capable of consistent product delivery, customization options, and responsive customer support throughout the procurement process.

Production scale considerations include lead times, inventory management capabilities, and geographic distribution networks. Suppliers with multiple manufacturing facilities and established logistics networks provide greater supply chain reliability and reduced risk of procurement disruptions during peak demand periods.

Technical Support and Warranty Coverage

Comprehensive technical support services distinguish quality suppliers from commodity providers. Fleet buyers should evaluate supplier capabilities in application engineering, troubleshooting assistance, and field support services. These support services prove invaluable during installation, maintenance, and problem resolution phases.

Warranty coverage terms reflect supplier confidence in product quality and provide financial protection against premature failures. Extended warranty periods, comprehensive coverage terms, and responsive claim processing procedures indicate supplier commitment to customer satisfaction and product reliability.

Cost Analysis and Total Ownership Considerations

Initial Purchase Price versus Lifecycle Costs

Effective cost analysis extends beyond initial purchase price to encompass total ownership costs throughout the component lifecycle. Premium ac condenser units may command higher initial investment but deliver superior longevity, reduced maintenance requirements, and improved energy efficiency.

Lifecycle cost calculations should include installation labor, maintenance frequency, energy consumption impact, and replacement intervals. These comprehensive cost models enable fleet managers to make informed decisions based on total economic impact rather than initial purchase price alone.

Volume Pricing and Fleet Discounts

Fleet purchasing power enables negotiation of volume pricing arrangements and specialized discount structures. Large-volume commitments often qualify for tiered pricing, extended payment terms, and exclusive supplier partnerships that reduce overall procurement costs.

Volume pricing negotiations should consider annual consumption projections, inventory management requirements, and seasonal demand variations. Structured purchasing agreements provide cost predictability and ensure consistent product availability throughout the procurement cycle.

Installation and Maintenance Considerations

Installation Requirements and Complexity

Installation requirements significantly impact total ownership costs and operational efficiency. AC condenser units with standardized mounting configurations, pre-assembled components, and clear installation documentation reduce labor time and minimize installation errors.

Fleet managers should evaluate installation complexity, required tools, and technician skill levels when selecting ac condenser suppliers. Simplified installation procedures reduce downtime, lower labor costs, and improve maintenance scheduling flexibility across fleet operations.

Maintenance Schedules and Service Requirements

Maintenance requirements vary significantly among different ac condenser designs and construction materials. Units with enhanced corrosion resistance, improved fin designs, and robust construction typically require less frequent service intervals and reduced maintenance intensity.

Fleet buyers should establish clear maintenance protocols, service interval recommendations, and preventive care procedures for selected ac condenser units. These protocols ensure optimal performance, extend component lifespan, and prevent unexpected failures that could disrupt fleet operations.

Frequently Asked Questions

How often should fleet AC condensers be replaced?

AC condenser replacement intervals depend on operating conditions, maintenance practices, and component quality. Typical replacement cycles range from 5-8 years for standard applications, though premium units may achieve longer service life. Regular inspection and preventive maintenance can significantly extend component lifespan and identify potential issues before failure occurs.

What are the signs of AC condenser failure in fleet vehicles?

Common indicators of ac condenser failure include reduced cooling performance, visible refrigerant leaks, corrosion damage, and abnormal system pressures. Fleet managers should implement regular inspection protocols to identify these warning signs early and schedule replacements before complete system failure occurs.

Can aftermarket AC condensers match OEM performance standards?

Quality aftermarket ac condenser units can meet or exceed OEM performance standards when properly selected and manufactured to appropriate specifications. Fleet buyers should verify compatibility, performance ratings, and quality certifications to ensure aftermarket components provide reliable service equivalent to original equipment.

What environmental factors affect AC condenser selection for fleets?

Environmental considerations include ambient temperature ranges, humidity levels, road salt exposure, and dust conditions. These factors influence material selection, coating requirements, and maintenance schedules. Fleet operations in harsh environments benefit from enhanced corrosion protection and robust construction materials that withstand challenging operating conditions.