Heavy-duty and commercial transport vehicles rely on robust air conditioning systems to maintain optimal operating conditions for both cargo preservation and driver comfort. The ac condenser serves as a critical component in these demanding applications, where extreme temperatures, extended operating hours, and challenging environmental conditions test the limits of automotive cooling technology. Commercial vehicles such as long-haul trucks, delivery vans, refrigerated transport units, and construction equipment require specialized ac condenser designs that can withstand constant vibration, temperature fluctuations, and heavy-duty operational demands while delivering consistent performance across thousands of miles and operating hours.

Essential Functions of AC Condensers in Commercial Applications

Heat Dissipation and Thermal Management

The primary function of an ac condenser in commercial vehicles involves converting high-pressure refrigerant vapor into liquid form through efficient heat dissipation. Heavy-duty applications generate significantly more heat than standard passenger vehicles due to larger engine compartments, extended idle times, and increased cooling demands. Commercial ac condenser units must effectively manage thermal loads that can exceed those found in passenger cars by 200-300 percent, requiring enhanced surface area and improved airflow design to maintain optimal refrigeration cycle efficiency.

Advanced thermal management becomes particularly crucial in refrigerated transport applications where cargo temperature control directly impacts product integrity and regulatory compliance. The ac condenser must maintain consistent performance even when ambient temperatures reach extreme highs, ensuring that refrigeration systems can preserve perishable goods throughout long-distance hauls and multiple delivery stops.

Pressure Regulation and System Stability

Commercial vehicle ac condenser systems must handle variable pressure conditions resulting from fluctuating engine speeds, changing load conditions, and diverse operating environments. The condenser design incorporates robust pressure regulation mechanisms that prevent system failures during peak demand periods while maintaining optimal refrigerant flow rates. This stability proves essential for commercial operations where air conditioning downtime can result in significant operational costs and cargo losses.

Professional-grade ac condenser units feature reinforced construction materials and enhanced mounting systems that resist vibration-induced stress fractures common in heavy-duty applications. These design improvements ensure consistent pressure maintenance across varied operating conditions, from highway cruising to urban stop-and-go traffic patterns that characterize commercial vehicle usage.

Design Specifications for Heavy-Duty Performance

Material Construction and Durability

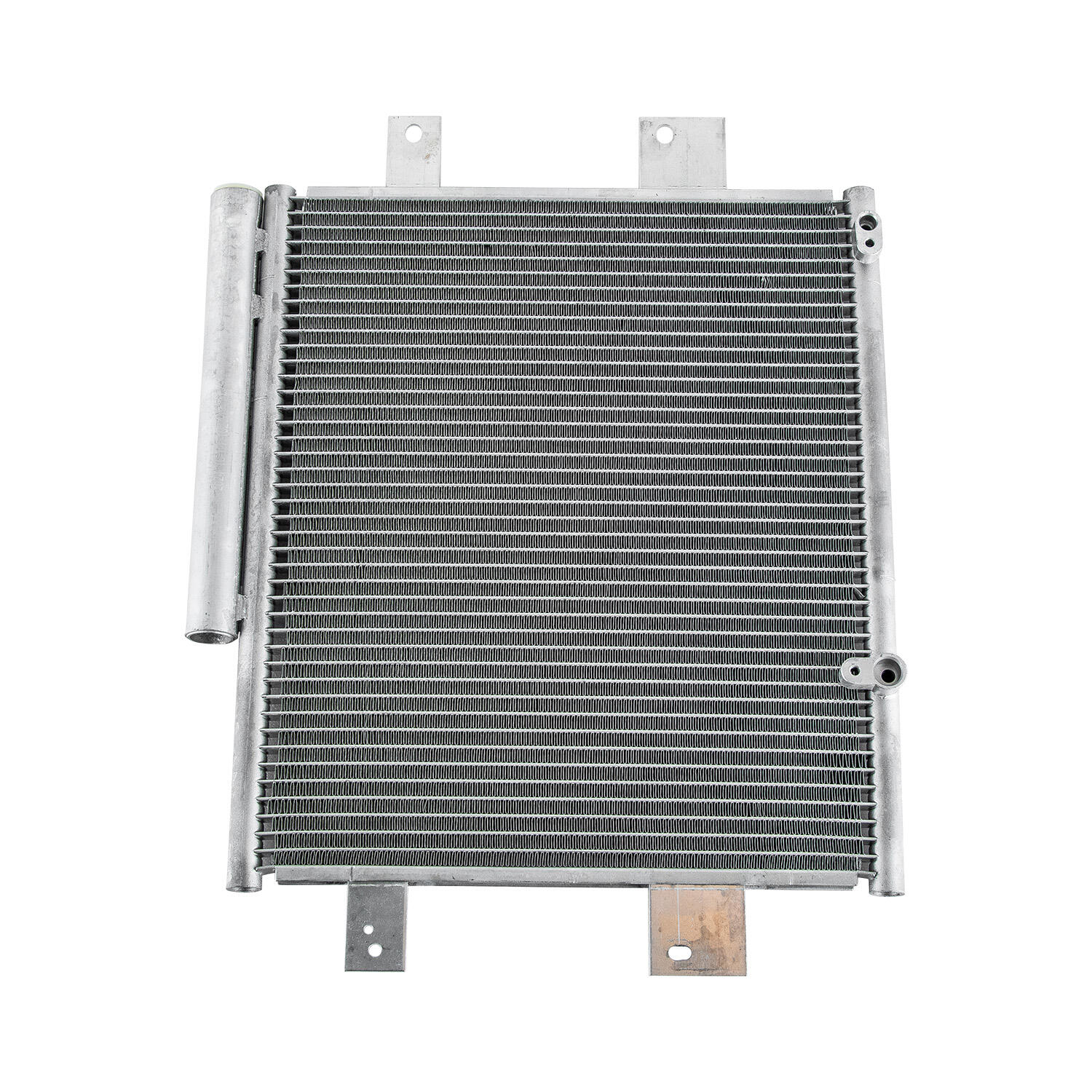

Heavy-duty ac condenser construction utilizes advanced aluminum alloys and corrosion-resistant coatings specifically engineered for commercial vehicle environments. These materials provide superior thermal conductivity while withstanding exposure to road salt, industrial chemicals, and extreme weather conditions that commercial vehicles encounter during regular operations. The enhanced material specifications ensure extended service life that aligns with commercial vehicle maintenance schedules and operational requirements.

Reinforced tube and fin designs within the ac condenser core provide additional structural integrity necessary for withstanding constant vibration and thermal cycling inherent in commercial applications. Professional-grade condensers incorporate thicker wall construction and improved joint welding techniques that prevent premature failure modes common in standard automotive applications when subjected to heavy-duty operational stresses.

Enhanced Cooling Capacity and Efficiency

Commercial ac condenser systems feature enlarged surface areas and optimized fin configurations that maximize heat transfer efficiency while accommodating the increased cooling demands of heavy-duty applications. These design enhancements enable effective operation in challenging environments where standard condensers would struggle to maintain adequate cooling performance. The expanded cooling capacity proves particularly valuable for vehicles operating in high-temperature climates or those requiring continuous air conditioning operation.

Advanced airflow management through the ac condenser core utilizes strategically positioned louvers and enhanced fan configurations that optimize cooling air distribution across the entire condenser surface. This comprehensive approach to thermal management ensures consistent performance regardless of vehicle speed or ambient conditions, providing reliable climate control for both driver comfort and cargo preservation requirements.

Installation and Integration Considerations

Mounting System Requirements

Heavy-duty vehicle ac condenser installation requires specialized mounting hardware designed to accommodate increased vibration levels and thermal expansion characteristics specific to commercial applications. Professional installation procedures ensure proper condenser positioning that maximizes airflow while providing adequate clearance for service access and component protection. The mounting system must maintain structural integrity throughout the extended service intervals typical of commercial vehicle operations.

Proper ac condenser mounting also considers the unique space constraints found in commercial vehicle engine compartments, where multiple auxiliary systems compete for available real estate. Integration planning must account for refrigeration lines, electrical connections, and service accessibility while ensuring optimal condenser performance through adequate air circulation and heat dissipation pathways.

System Compatibility and Performance Optimization

Commercial vehicle ac condenser selection must consider compatibility with existing refrigeration components, electrical systems, and vehicle-specific operational requirements. Proper system matching ensures optimal performance while preventing premature component failure that could result in costly downtime and repair expenses. Professional consultation during component selection helps identify the most suitable condenser specifications for specific commercial applications.

Performance optimization involves calibrating the ac condenser operation with engine management systems, auxiliary cooling components, and climate control electronics to achieve maximum efficiency. This integrated approach ensures that the condenser operates within optimal parameters while contributing to overall vehicle fuel economy and operational cost management objectives important to commercial fleet operators.

Maintenance and Service Requirements

Preventive Maintenance Protocols

Commercial ac condenser maintenance involves comprehensive inspection procedures that address the unique challenges associated with heavy-duty vehicle operations. Regular cleaning protocols remove accumulated debris, road grime, and environmental contaminants that can impair heat transfer efficiency and lead to premature system failure. Professional maintenance schedules account for the accelerated wear patterns typical of commercial vehicle applications, ensuring optimal condenser performance throughout extended service intervals.

Preventive maintenance also includes refrigerant system leak detection, pressure testing, and component inspection procedures that identify potential issues before they result in complete system failure. These proactive approaches help maintain consistent ac condenser operation while minimizing unexpected downtime that can significantly impact commercial vehicle productivity and operational schedules.

Performance Monitoring and Diagnostics

Advanced diagnostic procedures for commercial ac condenser systems utilize specialized equipment to monitor system pressures, temperatures, and refrigerant flow characteristics that indicate optimal performance levels. Professional diagnostic protocols help identify efficiency degradation trends that may signal impending component failure or system optimization opportunities. Regular performance monitoring ensures that the condenser continues operating at peak efficiency throughout its service life.

Comprehensive diagnostic procedures also evaluate ac condenser integration with other vehicle systems, identifying potential conflicts or inefficiencies that could compromise overall cooling performance. This systematic approach to system evaluation helps maintain optimal condenser operation while supporting broader vehicle performance and reliability objectives critical to commercial operations.

Industry Applications and Specialized Requirements

Refrigerated Transport and Cold Chain Management

Refrigerated transport vehicles require specialized ac condenser systems capable of supporting auxiliary refrigeration units while maintaining cab climate control functionality. These applications demand enhanced cooling capacity and system reliability that ensures temperature-sensitive cargo remains within specified ranges throughout transportation cycles. The ac condenser must operate efficiently across varying ambient conditions while supporting both primary vehicle air conditioning and auxiliary refrigeration system requirements.

Cold chain management applications place additional demands on ac condenser performance, requiring consistent operation during extended idle periods and frequent door openings that challenge system efficiency. Professional-grade condensers designed for these applications incorporate enhanced capacity reserves and improved thermal management capabilities that maintain optimal performance despite fluctuating cooling loads typical of refrigerated transport operations.

Construction and Industrial Equipment

Construction vehicles and industrial equipment utilize ac condenser systems engineered for extreme environmental conditions, including high dust levels, chemical exposure, and continuous heavy-duty operation. These applications require enhanced filtration capabilities and corrosion-resistant construction materials that maintain performance despite challenging operating environments. The condenser design must accommodate frequent cleaning cycles and replacement procedures typical of industrial maintenance schedules.

Industrial equipment ac condenser applications often involve integration with hydraulic cooling systems and other auxiliary components that share cooling circuit resources. This shared system approach requires careful design consideration to ensure that the condenser can effectively support multiple cooling requirements without compromising performance in any individual application area critical to equipment operation.

FAQ

What factors determine the appropriate ac condenser size for commercial vehicles

Commercial vehicle ac condenser sizing depends on several critical factors including cab volume, expected cooling load, ambient operating temperatures, and auxiliary cooling requirements. Vehicle weight class, typical duty cycle, and geographic operating regions also influence condenser capacity requirements. Professional sizing calculations consider heat load from engine compartment proximity, solar gain through large windshield areas, and additional cooling demands from sleeper compartments or specialized equipment installations.

How often should commercial vehicle ac condenser systems receive professional maintenance

Commercial ac condenser systems typically require professional inspection and cleaning every 25,000 to 50,000 miles, depending on operating conditions and environmental exposure. Vehicles operating in dusty environments or coastal areas with salt exposure may need more frequent service intervals. Comprehensive system evaluation should occur annually or according to manufacturer specifications, including refrigerant pressure testing, leak detection, and performance verification to ensure optimal cooling efficiency and prevent costly system failures.

What are the most common ac condenser failure modes in heavy-duty applications

Common ac condenser failure modes in commercial vehicles include fin damage from road debris, corrosion from environmental exposure, refrigerant leaks at connection points, and reduced efficiency from accumulated contamination. Vibration-induced stress fractures and mounting hardware failure also occur frequently in heavy-duty applications. Regular inspection and preventive maintenance help identify these issues early, preventing complete system failure and minimizing operational downtime costs.

Can aftermarket ac condenser units provide adequate performance for commercial applications

Quality aftermarket ac condenser units can provide excellent performance for commercial applications when properly selected and professionally installed. Key considerations include ensuring adequate cooling capacity, proper dimensional fit, and construction materials suitable for heavy-duty service. Professional consultation helps identify aftermarket options that meet or exceed original equipment specifications while providing potential cost savings and improved availability for fleet maintenance operations.

Table of Contents

- Essential Functions of AC Condensers in Commercial Applications

- Design Specifications for Heavy-Duty Performance

- Installation and Integration Considerations

- Maintenance and Service Requirements

- Industry Applications and Specialized Requirements

-

FAQ

- What factors determine the appropriate ac condenser size for commercial vehicles

- How often should commercial vehicle ac condenser systems receive professional maintenance

- What are the most common ac condenser failure modes in heavy-duty applications

- Can aftermarket ac condenser units provide adequate performance for commercial applications