Automotive air conditioning systems have become essential components in modern vehicles, directly impacting both passenger comfort and overall vehicle energy efficiency. The design and performance characteristics of an ac condenser play a crucial role in determining how efficiently a vehicle's climate control system operates. Understanding the intricate relationship between condenser design and energy consumption helps manufacturers optimize their cooling systems while meeting increasingly stringent fuel economy standards. The ac condenser serves as the heat rejection component in automotive air conditioning systems, converting refrigerant vapor back to liquid form while dissipating thermal energy to the surrounding environment.

Fundamental Principles of AC Condenser Operation

Heat Exchange Mechanisms in Automotive Condensers

The fundamental operation of an ac condenser relies on efficient heat transfer between the hot refrigerant vapor and the ambient air flowing through the condenser core. When high-pressure, high-temperature refrigerant vapor enters the condenser from the compressor, it must reject sufficient heat to facilitate phase change from vapor to liquid. This process requires careful consideration of heat exchanger design parameters including surface area, airflow patterns, and material properties. The effectiveness of this heat rejection directly correlates with the overall efficiency of the entire air conditioning system.

Modern ac condenser designs incorporate advanced heat transfer enhancement techniques to maximize thermal performance while minimizing pressure drop penalties. Microchannel technology, fin optimization, and improved tube geometries contribute to enhanced heat exchange rates. The relationship between refrigerant-side and air-side heat transfer coefficients determines the overall thermal conductance of the condenser assembly. Engineers must balance these competing factors to achieve optimal energy efficiency without compromising cooling capacity or system reliability.

Refrigerant Flow Dynamics and Pressure Management

Efficient refrigerant flow distribution throughout the ac condenser directly impacts energy consumption and cooling performance. Non-uniform flow distribution can lead to localized hot spots, reduced heat transfer effectiveness, and increased pressure drop across the heat exchanger. Advanced condenser designs incorporate flow distribution devices, headers, and manifold systems to ensure consistent refrigerant flow through all heat transfer passages. Proper refrigerant flow management minimizes the work required from the compressor while maximizing heat rejection capacity.

Pressure drop characteristics within the condenser significantly influence overall system energy efficiency. Excessive pressure drop increases the discharge pressure at the compressor outlet, requiring additional compressor work and reducing system coefficient of performance. Modern condenser designs optimize internal flow passages to minimize pressure drop while maintaining adequate heat transfer surface area. The balance between heat transfer enhancement and pressure drop penalties represents a critical design optimization challenge for automotive HVAC engineers.

Design Parameters Affecting Energy Efficiency

Core Geometry and Heat Transfer Surface Area

The physical dimensions and geometric configuration of an ac condenser core directly determine its thermal performance and energy efficiency characteristics. Larger heat transfer surface area generally provides improved heat rejection capacity, allowing the system to operate at lower condensing pressures and temperatures. However, increased surface area typically results in larger, heavier components that may negatively impact vehicle packaging and fuel economy. Engineers must optimize core dimensions to achieve the best balance between thermal performance and system constraints.

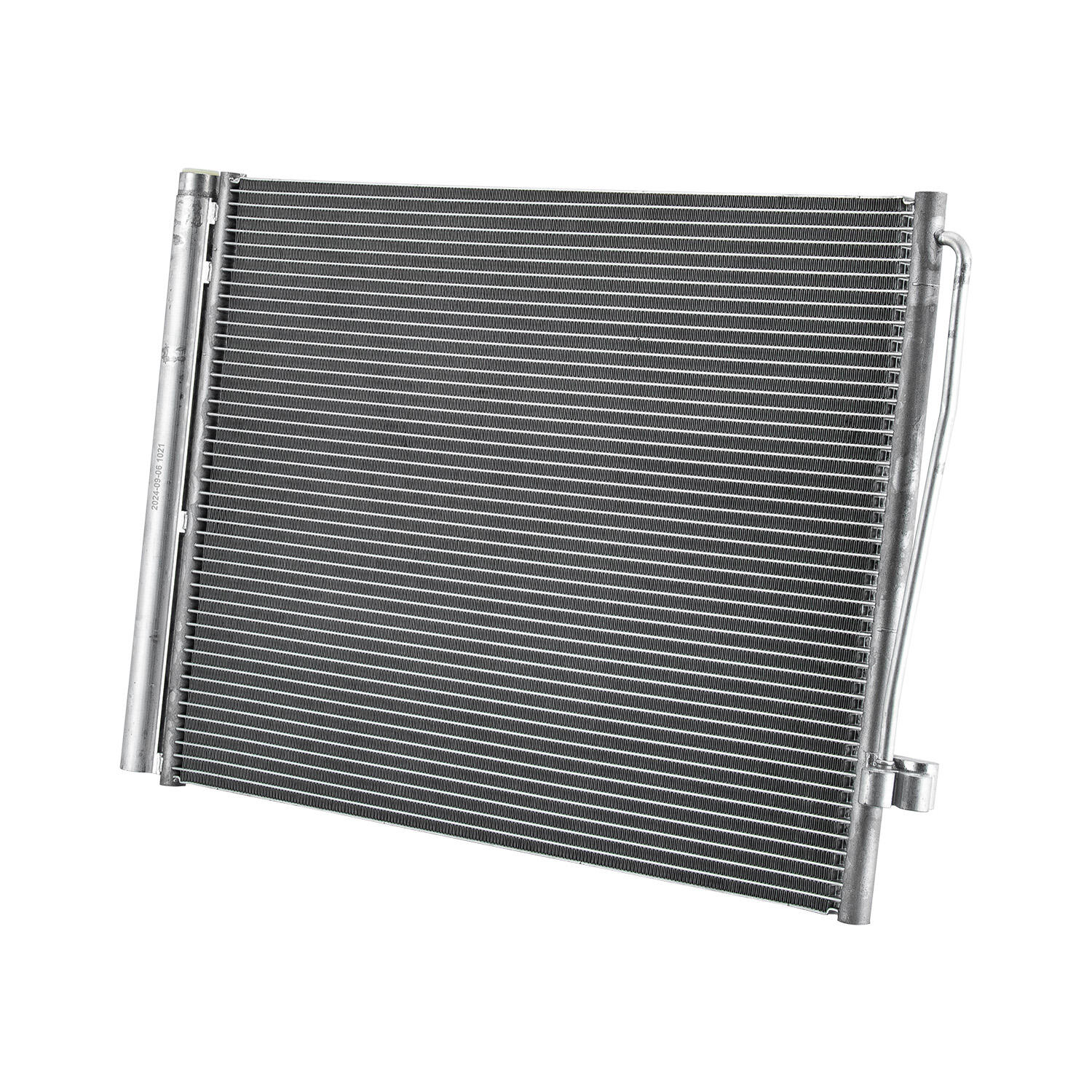

Modern automotive ac condenser designs utilize advanced manufacturing techniques to maximize surface area density within compact packages. Microchannel heat exchangers offer significantly higher surface area-to-volume ratios compared to traditional tube-and-fin designs. Enhanced fin geometries, including louvered fins, wavy fins, and perforated surfaces, increase heat transfer coefficients while maintaining reasonable pressure drop characteristics. These design innovations enable smaller, lighter condensers that deliver improved energy efficiency performance.

Material Selection and Thermal Conductivity

The selection of materials for ac condenser construction significantly impacts both thermal performance and long-term durability. Aluminum alloys dominate modern automotive condenser construction due to their excellent thermal conductivity, corrosion resistance, and lightweight properties. The thermal conductivity of condenser materials directly affects heat transfer rates between the refrigerant and ambient air. Higher thermal conductivity materials enable more efficient heat rejection, reducing the temperature difference required for adequate cooling performance.

Advanced aluminum alloys and manufacturing processes continue to improve ac condenser thermal performance while reducing weight and cost. Brazing techniques create permanent joints between fins, tubes, and headers that eliminate thermal resistance at component interfaces. Surface treatments and coatings protect against corrosion while maintaining optimal thermal properties. Material innovations contribute to enhanced energy efficiency by enabling more compact, lighter condenser designs that require less compressor work to achieve target cooling performance.

Airflow Management and External Design Factors

Fan System Integration and Air Movement

The integration between ac condenser design and cooling fan systems significantly affects overall energy efficiency in automotive applications. Proper fan selection, positioning, and control strategies ensure adequate airflow through the condenser core while minimizing parasitic power consumption. Electric cooling fans must be sized appropriately to provide sufficient air velocity through the heat exchanger without excessive energy consumption. The relationship between fan power consumption and condenser thermal performance represents a critical optimization parameter for overall system efficiency.

Advanced fan control algorithms adjust cooling fan speed based on ambient conditions, vehicle speed, and air conditioning load requirements. Variable speed fans provide optimal airflow rates while minimizing electrical power consumption during partial load conditions. The positioning of cooling fans relative to the ac condenser affects air distribution uniformity and heat transfer effectiveness. Proper integration between condenser design and cooling fan systems maximizes thermal performance while minimizing total energy consumption.

Vehicle Integration and Aerodynamic Considerations

The integration of ac condenser assemblies within vehicle front-end modules requires careful consideration of aerodynamic effects and thermal management. Condenser positioning relative to other heat exchangers, including engine radiators and charge air coolers, affects airflow distribution and thermal performance. Proper spacing between heat exchangers prevents thermal interference while maintaining compact packaging requirements. Vehicle manufacturers must balance condenser thermal performance with aerodynamic efficiency and overall vehicle design constraints.

Advanced computational fluid dynamics analysis enables optimization of condenser placement and external airflow management. Aerodynamic enhancements, including air dams, deflectors, and ducting systems, improve airflow through the condenser core while reducing overall vehicle drag. These design features contribute to improved ac condenser performance and reduced energy consumption for both air conditioning and vehicle propulsion systems. Integration optimization represents a key opportunity for enhancing overall automotive energy efficiency.

Advanced Technologies and Innovation Trends

Microchannel Heat Exchanger Technology

Microchannel technology represents a significant advancement in ac condenser design, offering superior thermal performance and reduced refrigerant charge requirements. These heat exchangers utilize small-diameter parallel channels that provide high surface area-to-volume ratios and enhanced heat transfer coefficients. Microchannel condensers typically demonstrate improved thermal effectiveness compared to conventional tube-and-fin designs while occupying less space and reducing system weight. The compact design enables more efficient vehicle packaging and improved fuel economy benefits.

Manufacturing advances in microchannel technology continue to reduce costs while improving performance characteristics. Advanced brazing processes create leak-tight joints between microchannel tubes and manifold headers. Optimized channel geometries and surface enhancement features maximize heat transfer while minimizing pressure drop penalties. These technological improvements enable ac condenser designs that deliver superior energy efficiency with reduced environmental impact through lower refrigerant charge requirements and improved system performance.

Smart Materials and Adaptive Design Features

Emerging smart materials and adaptive design concepts offer potential for future ac condenser innovations that automatically optimize performance based on operating conditions. Shape memory alloys and thermally responsive materials could enable condensers that adjust their thermal characteristics based on ambient temperature and system load requirements. These adaptive features could optimize energy efficiency across a wide range of operating conditions without requiring complex control systems or additional power consumption.

Advanced coating technologies and surface treatments continue to improve ac condenser performance and durability. Hydrophilic coatings enhance condensate drainage and reduce fouling, maintaining optimal heat transfer performance over extended service life. Anti-corrosion treatments protect against environmental degradation while preserving thermal properties. These material innovations contribute to sustained energy efficiency performance and reduced maintenance requirements throughout the vehicle operational life.

Performance Optimization and Testing Methodologies

Laboratory Testing and Performance Validation

Comprehensive testing methodologies ensure that ac condenser designs meet energy efficiency targets while maintaining reliability and durability requirements. Laboratory testing facilities simulate various operating conditions including ambient temperature variations, humidity levels, and airflow conditions. Standardized test procedures enable accurate comparison between different condenser designs and technologies. Performance validation testing confirms that design optimization efforts translate into measurable energy efficiency improvements in real-world applications.

Advanced instrumentation and data acquisition systems provide detailed performance characterization of ac condenser prototypes and production units. Thermal performance mapping identifies optimization opportunities and validates computational models used in the design process. Long-term durability testing ensures that energy efficiency benefits are maintained throughout the expected service life. These testing methodologies support continuous improvement in condenser design and manufacturing processes.

Computational Modeling and Design Optimization

Sophisticated computational modeling tools enable engineers to optimize ac condenser designs before physical prototyping and testing. Computational fluid dynamics simulations predict heat transfer performance, pressure drop characteristics, and airflow distribution within condenser assemblies. These modeling capabilities accelerate the design optimization process while reducing development costs and time requirements. Advanced modeling tools consider multiple design variables simultaneously to identify optimal configurations for energy efficiency and performance.

Machine learning algorithms and artificial intelligence techniques increasingly support ac condenser design optimization efforts. These advanced computational methods analyze large datasets from testing and simulation to identify design patterns that maximize energy efficiency. Optimization algorithms automatically explore design space to identify configurations that meet multiple performance objectives. These computational advances enable more sophisticated condenser designs that deliver superior energy efficiency while meeting stringent packaging and cost constraints.

FAQ

What factors determine ac condenser energy efficiency

The energy efficiency of an ac condenser depends on several key factors including heat transfer surface area, material thermal conductivity, refrigerant flow distribution, and airflow management. Larger surface area generally improves heat rejection efficiency, while proper refrigerant flow ensures uniform temperature distribution. Advanced materials with high thermal conductivity enhance heat transfer rates, and optimized airflow through the condenser core maximizes thermal performance while minimizing pressure drop penalties.

How does condenser design affect compressor power consumption

Condenser design directly influences compressor power consumption through its impact on system operating pressures and temperatures. More efficient condenser designs enable lower condensing pressures, reducing the work required from the compressor to maintain adequate cooling performance. Improved heat rejection capacity allows the system to operate at lower discharge temperatures, further reducing compressor power requirements. Optimized condenser designs can significantly reduce overall air conditioning system energy consumption.

What are the benefits of microchannel condenser technology

Microchannel ac condenser technology offers multiple benefits including improved thermal performance, reduced refrigerant charge requirements, and compact packaging. The high surface area-to-volume ratio of microchannel designs enhances heat transfer efficiency while reducing system weight and size. Lower refrigerant charge requirements reduce environmental impact and system costs. These advantages combine to deliver superior energy efficiency compared to traditional tube-and-fin condenser designs.

How can proper maintenance improve condenser energy efficiency

Regular maintenance of ac condenser systems significantly impacts energy efficiency and performance. Cleaning accumulated debris, dirt, and contaminants from condenser surfaces maintains optimal heat transfer rates and airflow characteristics. Proper refrigerant charging ensures correct system pressures and temperatures. Regular inspection and replacement of worn components prevents efficiency degradation over time. Well-maintained condenser systems operate at peak efficiency throughout their service life, minimizing energy consumption and operating costs.