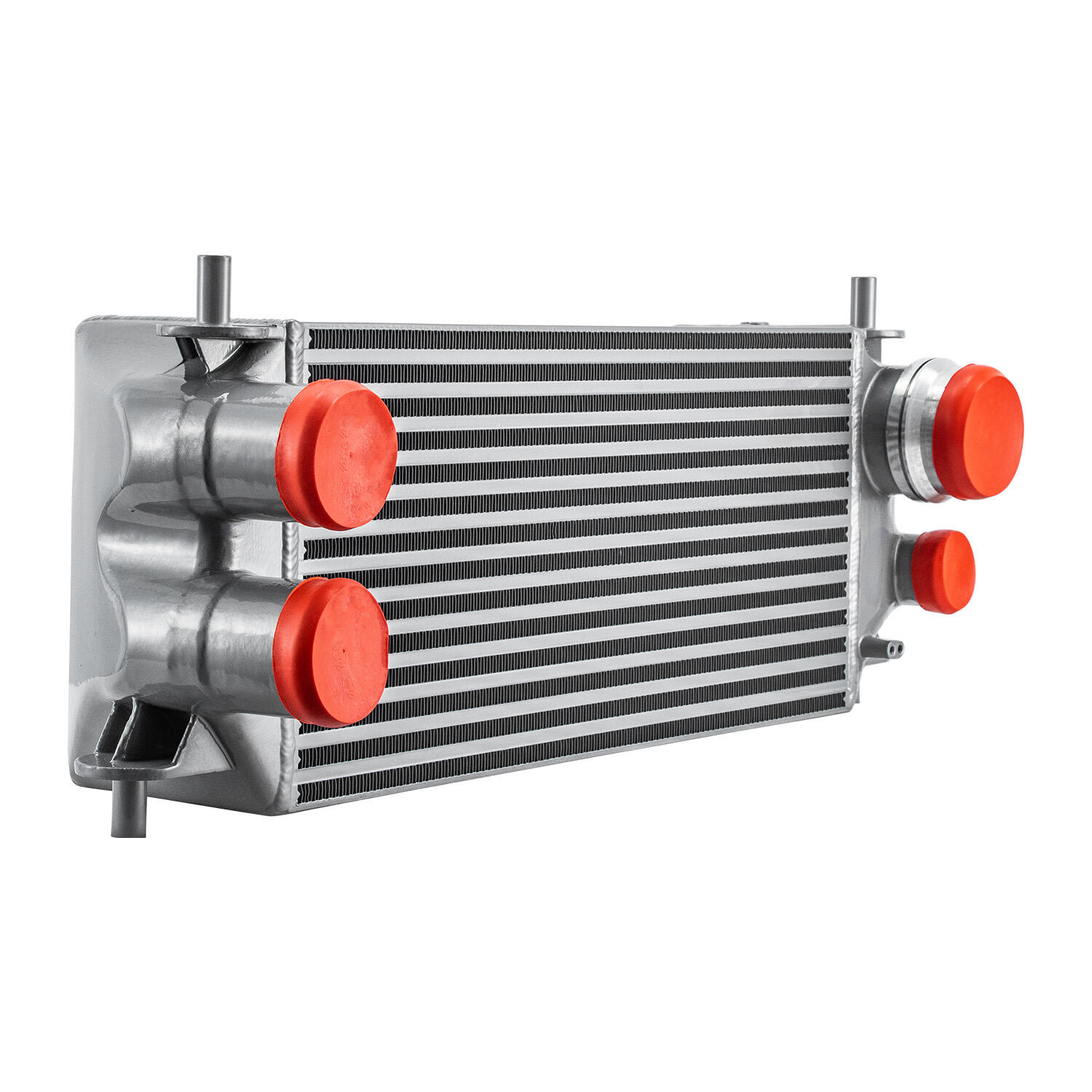

front mount intercooler

A front mount intercooler (FMIC) is a critical performance component designed to enhance engine efficiency and power output in turbocharged vehicles. This advanced cooling system is strategically positioned at the front of the vehicle, directly in the path of incoming airflow, maximizing its cooling potential. The primary function of an FMIC is to reduce the temperature of compressed air from the turbocharger before it enters the engine's combustion chamber. When air is compressed by the turbocharger, it becomes hot, which decreases its density and oxygen content. The FMIC addresses this issue by cooling the compressed air, making it denser and oxygen-rich, which results in more efficient combustion and increased power output. The design typically incorporates aluminum construction with internal fins that maximize heat dissipation, while the front mounting position ensures optimal exposure to ambient air. This positioning also provides better weight distribution compared to top-mount alternatives. Modern FMICs often feature precision-engineered end tanks and reinforced connection points to handle high boost pressures while maintaining structural integrity under various driving conditions.