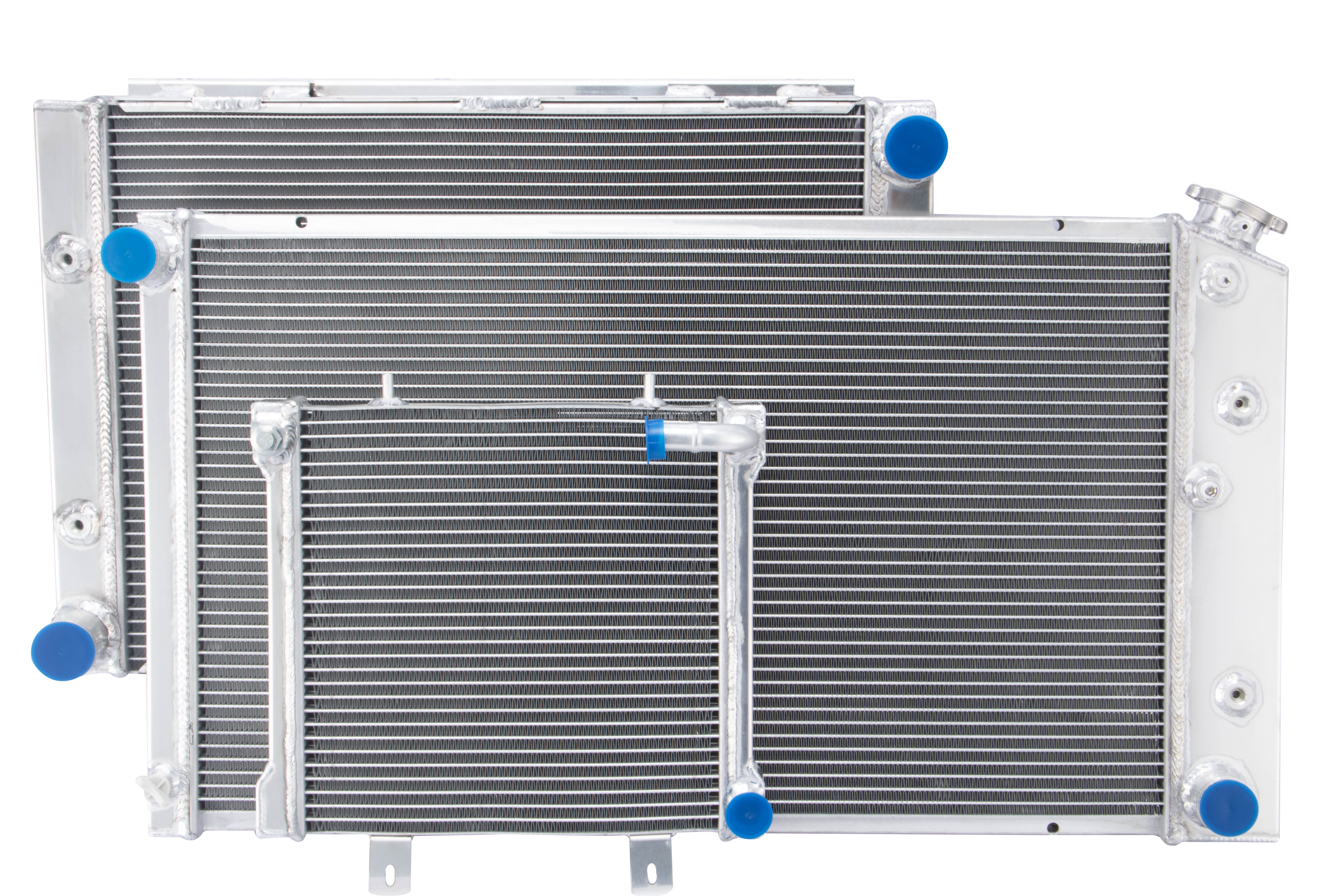

aluminium pastic radiator

The aluminum plastic radiator represents a significant advancement in heating technology, combining the durability of aluminum with the cost-effectiveness of plastic components. This innovative heating solution features a core structure made from high-grade aluminum fins bonded with specialized plastic end tanks and connecting pieces. The design incorporates multiple parallel water channels that maximize heat transfer efficiency while maintaining structural integrity. The radiator's construction allows for optimal heat distribution through its aluminum fins, while the plastic components reduce overall weight and manufacturing costs. These radiators are engineered to provide consistent temperature control in various applications, from residential heating systems to industrial processes. The unique combination of materials ensures excellent thermal conductivity through the aluminum sections while preventing corrosion and reducing weight through strategic plastic placement. Modern manufacturing techniques enable seamless integration between the aluminum and plastic components, creating a robust seal that prevents leakage and maintains system pressure. The radiator's design also includes advanced flow technology that minimizes water resistance and improves overall system efficiency. With its versatile mounting options and compatibility with various heating systems, the aluminum plastic radiator offers a reliable solution for diverse heating requirements.