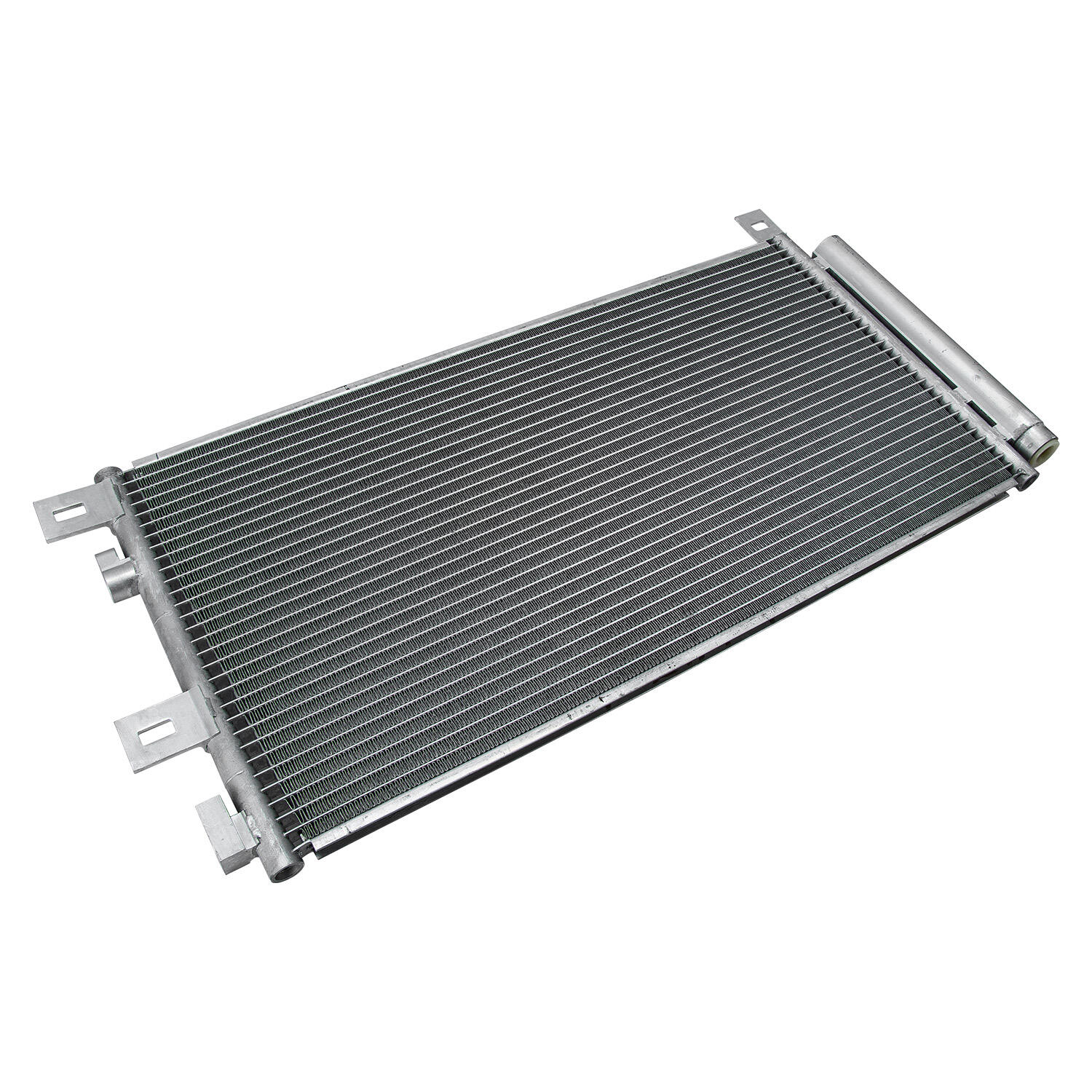

air con condenser

An air con condenser is a critical component in air conditioning systems, serving as the primary heat exchange mechanism that transforms hot refrigerant gas into liquid form. Located in the outdoor unit, this essential device consists of copper or aluminum coils designed to facilitate efficient heat transfer. The condenser operates by receiving high-pressure, high-temperature refrigerant vapor from the compressor and cooling it through a combination of forced air circulation and specialized heat exchange surfaces. As the refrigerant flows through the condenser coils, heat is released into the surrounding air, causing the refrigerant to condense into a liquid state. This process is fundamental to the refrigeration cycle and directly impacts the system's overall cooling efficiency. Modern air con condensers incorporate advanced technologies such as microchannel heat exchangers, enhanced fin designs, and corrosion-resistant coatings to maximize performance and durability. These units are carefully engineered to maintain optimal pressure levels and ensure consistent cooling output while minimizing energy consumption. The condenser's design also includes protective features to prevent damage from environmental factors and ensure reliable operation across various climate conditions.