โดยทั่วไป เครื่องปรับอากาศแบบ AC ความ คาดหวัง ใน ชีวิต

มาตรฐานอุตสาหกรรมสำหรับความทนทานของคอนเดนเซอร์

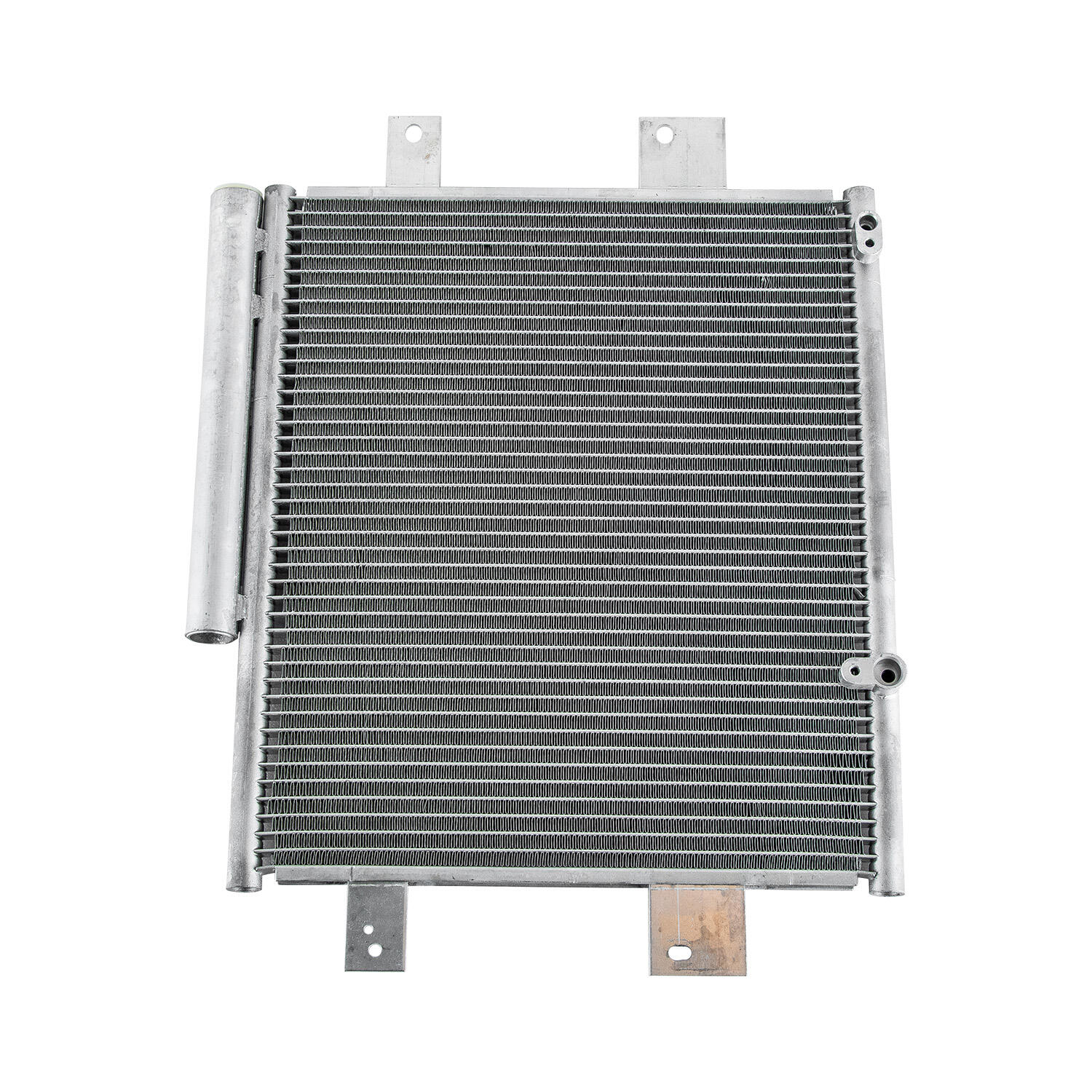

การรู้ว่าเครื่องควบแน่นระบบปรับอากาศ (AC condenser) จะใช้งานได้นานแค่ไหน มีความสำคัญมากเมื่อพิจารณาถึงประสิทธิภาพการทำความเย็นที่ดีและการวางแผนล่วงหน้า โดยทั่วไป หน่วยงานส่วนใหญ่มักจะใช้งานได้ระหว่าง 12 ถึง 15 ปี ตามคำแนะนำของสถาบันเครื่องปรับอากาศและเครื่องทำความร้อนและการทำให้เย็น (Air Conditioning, Heating and Refrigeration Institute: AHRI) แต่ก็ยังมีความแตกต่างกันอยู่มากเช่นกัน บางเครื่องอาจใช้งานได้นานกว่าขึ้นอยู่กับปัจจัยต่างๆ เช่น คุณภาพของวัสดุและกระบวนการผลิตตั้งแต่แรกเริ่ม เจ้าของบ้านควรเข้าใจตัวเลขเหล่านี้เป็นพิเศษ เพราะการรู้ว่าควรคาดหวังอะไรจะช่วยให้วางแผนล่วงหน้าเพื่อเปลี่ยนเครื่องในเวลาที่เหมาะสมได้ ท้ายที่สุดแล้ว ไม่มีใครอยากเจอปัญหาแบบไม่ทันตั้งตัวในช่วงที่อากาศร้อนจัด!

รูปแบบการใช้งานส่งผลต่อความทนทานอย่างไร

ความถี่ที่คอยล์ล้างอากาศ (AC condenser) ถูกนำมาใช้งานนั้นมีผลต่ออายุการใช้งานของมันอย่างมาก ระบบในบ้านพักอาศัยโดยทั่วไปมักไม่ได้ทำงานหนักเท่ากับระบบที่ใช้ในอาคารสำนักงานหรือสถานประกอบการซึ่งต้องทำงานตลอดทั้งวันเกือบทุกวัน ทำให้อายุการใช้งานลดลงเร็วกว่าปกติ สิ่งที่ควรคำนึงถึงเมื่อพิจารณาอายุเฉลี่ยของคอยล์ล้างอากาศคือช่วงเวลาบ่ายในฤดูร้อนที่ทุกคนเปิดเครื่องปรับอากาศเต็มกำลัง การเข้าใจว่าช่วงเวลาที่มีความต้องการสูงแบบนี้เกิดขึ้นเมื่อไร จะช่วยให้ประเมินอายุการใช้งานของอุปกรณ์ได้แม่นยำยิ่งขึ้น การบำรุงรักษาอย่างสม่ำเสมอถือเป็นสิ่งสำคัญเช่นกัน การทำความสะอาดคอยล์ที่สกปรกและคอยตรวจสอบระดับสารทำความเย็นไม่เพียงแค่เป็นแนวทางปฏิบัติที่ดี แต่ยังช่วยยืดอายุการใช้งานของระบบเครื่องปรับอากาศทั้งระบบได้อย่างมีนัยสำคัญ ผู้ใช้งานส่วนใหญ่พบว่าการดูแลงานพื้นฐานเหล่านี้สามารถทำให้เครื่องปรับอากาศของพวกเขายังคงทำงานได้อย่างราบรื่นเป็นเวลานานหลายปีเกินกว่าที่คาดคิดไว้ในตอนแรก

คู่มือแนะนำของผู้ผลิต กับ ประสิทธิภาพการทำงานจริง

ผู้ผลิตส่วนใหญ่จะให้คำแนะนำอย่างละเอียดเมื่อออกผลิตภัณฑ์ โดยเฉพาะคำแนะนำเกี่ยวกับการบำรุงรักษาเป็นประจำ เพื่อให้คอยล์คอนเดนเซอร์ของเครื่องปรับอากาศทำงานได้อย่างมีประสิทธิภาพสูงสุด แต่ความเป็นจริงมักไม่ตรงกับสิ่งที่เขียนไว้ เนื่องจากสภาพแวดล้อมแตกต่างกันมากในแต่ละพื้นที่ ส่งผลให้บางครั้งคอยล์คอนเดนเซอร์ไม่สามารถตอบสนองตามมาตรฐานที่คาดหวังได้ มีการศึกษาหลายครั้งที่แสดงให้เห็นว่า ระบบซึ่งถูกละเลยตามคำแนะนำของผู้ผลิต มักจะเกิดปัญหาขึ้นก่อนเวลาที่ควรจะต้องซ่อมแซมหรือเปลี่ยน ช่องว่างระหว่างทฤษฎีและการปฏิบัตินี้มีความสำคัญมากสำหรับเจ้าของบ้านที่พยายามหาคำตอบว่าอุปกรณ์ของตนเองจะมีอายุการใช้งานได้นานแค่ไหน การดูแลรักษาอย่างเหมาะสมด้วยการตรวจสอบและทำความสะอาดเป็นประจำ ไม่ใช่เพียงแค่คำแนะนำ แต่แทบจะเป็นสิ่งจำเป็น หากใครต้องการให้ระบบปรับอากาศมีอายุการใช้งานยาวนานโดยไม่เกิดการเสียหายแบบไม่คาดคิด

สัญญาณสำคัญที่บ่งชี้ว่าคุณต้องเปลี่ยนคอยล์คอนเดนเซอร์ของเครื่องปรับอากาศ

ประสิทธิภาพการเย็นลดลง และอากาศที่ออกมาอุ่น

เมื่อเครื่องปรับอากาศเริ่มมีปัญหาในการรักษาอุณหภูมิให้ห้องเย็น ปัญหานี้มักชี้ให้เห็นถึงข้อผิดพลาดที่เกิดขึ้นกับหน่วยคอนเดนเซอร์ (condenser unit) การตรวจสอบอุณหภูมิอย่างสม่ำเสมอจะช่วยยืนยันได้ว่าประสิทธิภาพในการทำความเย็นลดลงหรือไม่ ซึ่งทำให้การตรวจสอบระบบโดยรวมมีความสำคัญมาก การเปรียบเทียบประสิทธิภาพของระบบในอดีตกับปัจจุบันจะช่วยให้เข้าใจว่าเกิดอะไรขึ้นกับคอนเดนเซอร์ โดยทั่วไปเจ้าของบ้านมักจะสังเกตได้ว่าเครื่องปรับอากาศทำงานได้ไม่ดีเหมือนเดิมหลังใช้งานมาหลายฤดูกาล จนถึงจุดหนึ่งการเปลี่ยนคอนเดนเซอร์จึงกลายเป็นสิ่งจำเป็นเพื่อคืนประสิทธิภาพในการทำความเย็นให้กลับมาดีดังเดิม แม้ว่าการตัดสินใจเวลาที่เหมาะสมในการเปลี่ยนจะเป็นเรื่องที่ท้าทายเล็กน้อย เนื่องจากอาการของปัญหามักจะค่อยเป็นค่อยไปและไม่แสดงตัวชัดเจนแบบทันทีทันใด

การรั่วไหลของสารทำความเย็นอย่างต่อเนื่องและปัญหาความดัน

เมื่อสารทำความเย็นเริ่มรั่วไหลออกจากระบบเครื่องปรับอากาศ จะส่งผลให้ประสิทธิภาพการทำความเย็นลดลงอย่างชัดเจน หากไม่ได้ทำการแก้ไขการรั่วไหลเหล่านี้ให้ทันเวลาก็อาจทำให้เกิดค่าใช้จ่ายสูงขึ้นได้อย่างรวดเร็ว — เราเคยเห็นกรณีที่คอมเพรสเซอร์เสียหายจนใช้งานไม่ได้เลย การตรวจสอบมาตรวัดแรงดันเป็นประจำสามารถบ่งชี้ปัญหาภายในระบบได้มาก ค่าแรงดันที่อ่านได้ปกติถือเป็นสัญญาณที่ดี แต่หากค่าที่วัดได้ลดลงเรื่อย ๆ ตามระยะเวลา ก็มักหมายความว่ามีบางส่วนต้องเปลี่ยน ช่างเทคนิคส่วนใหญ่มักแนะนำเสมอว่าการรั่วของสารทำความเย็นที่เกิดซ้ำบ่อยครั้งมักบ่งชี้ถึงปัญหาที่ใหญ่กว่า เมื่อเกิดเหตุการณ์ดังกล่าวหลายครั้งแล้ว ควรขอความเห็นจากผู้เชี่ยวชาญเพื่อพิจารณาว่าควรเปลี่ยนชุดคอนเดนเซอร์ทั้งชุดแทนที่จะแก้ไขปัญหาเดิมซ้ำแล้วซ้ำเล่า

เสียงผิดปกติจากคอมเพรสเซอร์ขณะทำงาน

เสียงแปลก ๆ ที่ออกมาจากหน่วยคอนเดนเซอร์ เช่น เสียงเอี๊ยด หรือเสียงคล้ายการขูดขีด มักบ่งชี้ว่ามีบางสิ่งผิดปกติเกิดขึ้นภายในระบบกลไก เมื่อผู้ใช้ตั้งใจฟังและสังเกตเสียงเหล่านี้ เสียงดังกล่าวมักสอดคล้องกับปัญหาที่เกิดขึ้นเฉพาะเจาะจง ซึ่งช่วยให้เข้าใจได้ว่าอุปกรณ์ส่วนใดเกิดความเสียหาย การจดบันทึกรายละเอียดของเสียงเหล่านี้ไว้ก่อนเรียกช่างซ่อมมานั้นถือเป็นเรื่องสำคัญ เนื่องจากช่างจำเป็นต้องได้รับข้อมูลที่ชัดเจนเพื่อให้ทำงานได้อย่างมีประสิทธิภาพ และอย่าได้เพิกเฉยต่อเสียงเหล่านั้น เพราะเสียงแปลก ๆ เหล่านี้ไม่ใช่แค่เสียงรบกวนธรรมดา แต่เป็นสัญญาณเตือนภัยที่บ่งชี้ว่าอาจมีชิ้นส่วนบางอย่างจำเป็นต้องเปลี่ยนก่อนที่ปัญหาจะลุกลามและส่งผลให้เกิดค่าใช้จ่ายที่สูงขึ้นในอนาคต

สนิมหรือความเสียหายของคอยล์ที่มองเห็นได้

เมื่อคอนเดนเซอร์ถูกติดตั้งไว้ภายนอกอาคารเป็นเวลานาน สนิมมักจะกัดกร่อนเข้ามาตามกาลเวลา และส่งผลให้อายุการใช้งานและประสิทธิภาพการทำงานลดลง การตรวจสอบสภาพทางสายตาอย่างสม่ำเสมอจึงเป็นสิ่งสำคัญ เนื่องจากสามารถตรวจพบปัญหาได้ตั้งแต่ยังไม่ลุกลาม ความเสียหายที่คอยล์ทองแดงถือเป็นสัญญาณเตือนที่สำคัญ เราเคยเห็นหน่วยทำงานล้มเหลวอย่างรวดเร็วเมื่อมีคนเพิกเฉยต่อรอยบุบหรือคราบสนิมเล็กน้อยบนคอยล์ ควรรีบตรวจสอบทันทีแทนที่จะรอจนกระทั่งฤดูร้อนมาถึง การแก้ไขปัญหาเล็กน้อยในตอนนี้จะช่วยป้องกันปัญหาใหญ่ในภายหลัง และทำให้ระบบทำงานได้อย่างมีประสิทธิภาพในช่วงเวลาที่สำคัญที่สุด

ด้วยการเข้าใจสัญญาณเตือนเหล่านี้ คุณสามารถวางแผนบำรุงรักษาและเปลี่ยนชุดควบแน่นของเครื่องปรับอากาศได้ทันเวลา ช่วยยืดอายุการใช้งานและเพิ่มประสิทธิภาพของระบบเครื่องปรับอากาศ

ปัจจัยที่เร่งการสึกหรอของชุดควบแน่น

คอยล์อุดตันจากสิ่งสกปรกสะสม

เมื่อสิ่งสกปรก ใบไม้ และเศษวัสดุอื่นๆ เริ่มสะสมรอบระบบปรับอากาศ พวกมันมักจะติดอยู่ในคอยล์ ซึ่งจะปิดกั้นการไหลเวียนของอากาศและทำให้เครื่องปรับอากาศทำงานหนักกว่าปกติ ซึ่งมักนำไปสู่ปัญหาความร้อนสูงเกินไป แล้วจะเกิดอะไรขึ้นต่อไป? คอนเดนเซอร์เครื่องปรับอากาศมีอายุการใช้งานสั้นลงเกือบเท่าที่ควร เจ้าของบ้านส่วนใหญ่ไม่ได้ตระหนักถึงความสำคัญของการทำความสะอาดเป็นประจำต่อระบบของพวกเขา การศึกษาแสดงให้เห็นว่าเมื่อผู้คนดูแลรักษาเครื่องปรับอากาศอย่างสม่ำเสมอ เครื่องปรับอากาศของพวกเขามักจะทำงานได้ดีขึ้นและใช้งานได้นานขึ้น อีกหนึ่งแนวทางที่ชาญฉลาดคือการเลือกจัดสวนใกล้กับเครื่องปรับอากาศภายนอกอาคาร การปลูกไม้พุ่มหรือต้นไม้ใกล้กันเกินไปอาจทำให้มีเศษวัสดุสะสมมากขึ้น การเว้นพื้นที่รอบเครื่องปรับอากาศไว้บ้างจะช่วยป้องกันปัญหานี้และทำให้ระบบทำงานได้อย่างมีประสิทธิภาพสูงสุดในระยะยาว

การสัมผัสกับน้ำเค็มและการกัดกร่อนจากสารเคมี

เมื่อเครื่องปรับอากาศถูกนำไปใช้ในพื้นที่ที่มีน้ำเค็มโดยเฉพาะตามแนวชายฝั่งทะเล ชิ้นส่วนโลหะของเครื่องจะเกิดการกัดกร่อนเร็วกว่าปกติ งานวิจัยแสดงให้เห็นว่าเครื่องปรับอากาศที่ติดตั้งภายในระยะไม่กี่ไมล์จากทะเล มักมีอายุการใช้งานเพียงประมาณ 60% ของอายุที่ควรจะเป็น สารเกลือในอากาศจะกัดกินชิ้นส่วนต่างๆ ของเครื่องไปเรื่อยๆ จนทำให้เครื่องเสียหายก่อนเวลาอันควร สำหรับเจ้าของทรัพย์สินที่ต้องเผชิญกับสภาพเช่นนี้ การเปลี่ยนไปใช้วัสดุที่เป็นสแตนเลสหรือวัสดุที่ป้องกันสนิมอื่นๆ จะช่วยเพิ่มการปกป้องในระยะยาว วัสดุเหล่านี้ทนทานต่อสภาพแวดล้อมทางทะเลที่รุนแรงกว่า และช่วยประหยัดค่าใช้จ่ายในการเปลี่ยนวัสดุในอนาคต

ระดับสารทำความเย็นไม่เหมาะสม

การปรับระดับสารทำความเย็นให้ถูกต้องมีความสำคัญอย่างมากต่อประสิทธิภาพของคอนเดนเซอร์ การเติมสารทำความเย็นมากเกินไปหรือน้อยเกินไป อาจนำไปสู่การทำงานที่ไม่มีประสิทธิภาพของคอมเพรสเซอร์ และทำให้ชิ้นส่วนสึกหรอเร็วขึ้น จนกระทบต่อประสิทธิภาพของอุปกรณ์โดยรวม การใช้มาตรวัดอย่างถูกต้องจะช่วยให้ระดับสารทำความเย็นอยู่ในระดับที่เหมาะสม ช่วยป้องกันการเสียหายของอุปกรณ์ก่อนวัย และยืดอายุการใช้งานของอุปกรณ์ผ่านการบำรุงรักษาและการตรวจสอบอย่างสม่ำเสมอ

ความเครียดจากแรงสั่นสะเทือนและความล้มเหลวทางไฟฟ้า

เมื่อชิ้นส่วนไฟฟ้าถูกสั่นสะเทือนอย่างต่อเนื่อง อาจทำให้เกิดการเสียหาย โดยเฉพาะกับตัวควบแน่น (condenser) การตรวจสอบการเชื่อมต่อทางไฟฟ้าอย่างสม่ำเสมอจะช่วยให้พบปัญหาเล็กๆ ได้ก่อนที่จะลุกลามกลายเป็นปัญหาใหญ่ในอนาคต การศึกษาวิจัยแสดงให้เห็นว่า การยึดตัวควบแน่นให้มั่นคงนั้นช่วยลดการสึกหรอที่เกิดจากแรงสั่นสะเทือน ซึ่งเป็นเรื่องที่สมเหตุสมผล เนื่องจากฐานยึดที่มั่นคงจะช่วยลดการสั่นสะเทือนของระบบโดยรวม ช่างเทคนิคส่วนใหญ่จะบอกว่า การติดตั้งที่เหมาะสมสามารถยืดอายุการใช้งานของเครื่องปรับอากาศ และป้องกันปัญหาทางไฟฟ้าที่เกิดจากชิ้นส่วนที่หลวมและสั่น rattling อยู่ภายใน

กรอบแนวทางการตัดสินใจระหว่างซ่อมแซมกับเปลี่ยนใหม่

การวิเคราะห์ต้นทุนโดยใช้หลักการวิธีการกฎเกณฑ์ 5,000

กฎ 5,000 บาทนี้ใช้ได้ค่อนข้างดีเมื่อต้องตัดสินใจว่าจะซ่อมหรือเปลี่ยนระบบ HVAC เก่า ให้คูณอายุของเครื่องปรับอากาศ (ปี) ด้วยค่าซ่อมที่อาจเกิดขึ้น จากนั้นดูว่าผลรวมนี้เกิน 5,000 บาทหรือไม่ หลายคนพบว่าการคำนวณง่ายๆ นี้มีประโยชน์ในการตัดสินใจเกี่ยวกับระบบทำความร้อนและระบบทำความเย็นของตน ที่ปรึกษาด้านอสังหาริมทรัพย์และช่างเทคนิค HVAC มักแนะนำวิธีนี้เพราะเห็นว่าได้ผลจริงกับทั้งเจ้าของบ้านและเจ้าของธุรกิจที่ต้องการใช้จ่ายอย่างมีประสิทธิภาพ สิ่งที่สมเหตุสมผลในกรณีนี้คือ การหลีกเลี่ยงสถานการณ์ที่ผู้คนต้องเสียเงินซ่อมเครื่องเก่าที่ใช้งานมานาน แล้วกลับพบปัญหาอื่นๆ ตามมาเนื่องจากเครื่องยนต์ที่เสื่อมสภาพตามธรรมชาติ

ข้อแลกเปลี่ยนระหว่างอายุและประสิทธิภาพในหน่วยที่ใช้มานาน

เครื่องปรับอากาศที่ใช้งานมานานหลายทศวรรษมักทำงานหนักกว่าที่ควร ซึ่งหมายความว่าค่าไฟฟ้าในแต่ละเดือนจะสูงขึ้น ตัวเลขก็ไม่โกหกเช่นกันเมื่อพิจารณาถึงระบบต่าง ๆ ที่ใช้งานมาเกิน 15 ปีแล้ว การทำให้เครื่องเหล่านี้ยังคงทำงานต่อไปโดยทั่วไปมักจะเสียค่าใช้จ่ายมากขึ้นโดยรวม เนื่องจากกินไฟฟ้าจำนวนมากและมักขัดข้องอยู่เสมอ เจ้าของบ้านควรพิจารณาอย่างใกล้ชิดว่าเครื่องเก่าเหล่านี้ส่งผลต่อกระเป๋าของตนอย่างไร เมื่อผู้คนเปลี่ยนเครื่องรุ่นเก่าเป็นเครื่องใหม่ พวกเขามักจะเห็นประสิทธิภาพที่ดีขึ้นตั้งแต่วันแรกที่ใช้งาน รวมถึงค่าใช้จ่ายรายเดือนที่ลดลงแน่นอน การซื้อระบบใหม่อาจต้องจ่ายเงินก้อนในตอนแรก แต่หลายคนพบว่าการลดการสูญเสียพลังงานนั้นคุ้มค่าใช้จ่ายอย่างรวดเร็ว แทนที่จะเสียเวลาแก้ปัญหาเครื่องเก่าที่ล้าสมัยซึ่งไม่ยอมหยุดทำงาน

ข้อพิจารณาด้านสิ่งแวดล้อมสำหรับประเภทของสารทำความเย็น

เมื่อพิจารณาว่าจะซ่อมแซมหรือเปลี่ยนเครื่องปรับอากาศใหม่ สิ่งแวดล้อมย่อมมีบทบาทสำคัญ ระบบเก่าหลายระบบยังคงมีสารทำความเย็น เช่น R22 หรือ Freon ซึ่งถูกแบนมานานแล้วเพราะเป็นอันตรายต่อสิ่งแวดล้อม สารเหล่านี้มีส่วนทำให้ชั้นโอโซนลดลง และก่อให้เกิดก๊าซเรือนกระจก การเปลี่ยนมาใช้สารทำความเย็นรุ่นใหม่จึงมีประโยชน์ต่อสิ่งแวดล้อมอย่างชัดเจน อีกทั้งยังคุ้มค่าทางการเงินด้วย เพราะรัฐบาลมักมีสิทธิพิเศษต่าง ๆ ในการส่งเสริมการใช้เทคโนโลยีสีเขียว เมื่อกฎระเบียบต่าง ๆ เริ่มเข้มงวดมากขึ้นทั่วประเทศเกี่ยวกับการใช้สารทำความเย็นที่ถูกกฎหมาย ผู้คนจึงหันมาเลือกเปลี่ยนเครื่องปรับอากาศที่ใช้สารที่ได้รับอนุญาต เช่น R-410A หรือแม้แต่ทางเลือกใหม่อย่าง R-454B การเปลี่ยนแปลงนี้ไม่เพียงช่วยปกป้องโลกเท่านั้น แต่ยังทำให้ระบบปรับอากาศสอดคล้องกับมาตรฐานอาคารในปัจจุบัน และหลีกเลี่ยงค่าปรับที่อาจเกิดขึ้นในอนาคตจากการใช้สารที่ล้าสมัย

กลยุทธ์การบำรุงรักษาเพื่อยืดอายุการใช้งานคอนเดนเซอร์

ความถี่ที่เหมาะสมในการทำความสะอาดคอยล์

การทำความสะอาดคอยล์คอนเดนเซอร์ของเครื่องปรับอากาศให้สะอาดมีความสำคัญอย่างมาก ในการทำให้เครื่องทำงานได้อย่างมีประสิทธิภาพและใช้งานได้ยาวนานขึ้น เมื่อมีสิ่งสกปรกสะสมบนคอยล์ จะทำให้กระบวนการถ่ายเทความร้อนทำงานได้ไม่เต็มที่ และทำให้ระบบต้องทำงานหนักกว่าที่จำเป็น ส่งผลให้สิ้นเปลืองพลังงานไฟฟ้า ช่างเทคนิคส่วนใหญ่แนะนำว่าควรทำความสะอาดอย่างทั่วถึงทุกๆ สามถึงหกเดือน โดยเฉพาะในกรณีที่ตัวเครื่องภายนอกตั้งอยู่ใต้ต้นไม้ที่มีใบไม้ร่วงหล่น หรือใกล้พื้นที่ก่อสร้างที่ฝุ่นละอองมักจะสะสม การบำรุงรักษาอย่างสม่ำเสมอจะช่วยให้อากาศไหลเวียนได้อย่างราบรื่นภายในระบบ และลดความเครียดที่เกิดขึ้นกับชิ้นส่วนต่างๆ ผลลัพธ์ที่ได้คือ การทำความเย็นที่ดีขึ้นทั่วทั้งบ้าน และปัญหาขัดข้องที่เกิดขึ้นโดยไม่คาดคิดลดน้อยลงในระยะยาว

จุดตรวจสอบโดยผู้เชี่ยวชาญ

การตรวจเช็กโดยช่างผู้เชี่ยวชาญเป็นประจำ อาจเป็นวิธีที่ดีที่สุดในการตรวจพบปัญหาของคอนเดนเซอร์เครื่องปรับอากาศก่อนที่ปัญหาเล็กๆ จะกลายเป็นเรื่องใหญ่ที่สร้างความรำคาญให้กับเจ้าของบ้าน ในระหว่างการตรวจเช็กเหล่านี้ ช่างมักจะตรวจสอบระดับสารทำความเย็น และสแกนชิ้นส่วนต่างๆ เพื่อหาร่องรอยการสึกหรอที่คนทั่วไปอาจไม่เห็นด้วยตาเปล่า สิ่งที่ทำให้การตรวจเช็กเหล่านี้มีคุณค่าคือ เทคนิคที่ผ่านการรับรองสามารถติดตามแนวโน้มประสิทธิภาพของเครื่องในระยะยาว ซึ่งช่วยให้พวกเขาตรวจพบปัญหาเล็กน้อยก่อนที่จะลุกลามจนกลายเป็นค่าซ่อมแซมที่แพงตามมา ผู้เชี่ยวชาญด้านระบบปรับอากาศส่วนใหญ่แนะนำให้ทำการประเมินระบบโดยสมบูรณ์อย่างน้อยปีละครั้ง การบำรุงรักษาแบบเชิงรุกนี้ไม่เพียงแต่ช่วยยืดอายุการใช้งานของอุปกรณ์เท่านั้น แต่ยังช่วยให้เครื่องทำงานได้อย่างมีประสิทธิภาพตลอดช่วงฤดูร้อนที่ความต้องการในการทำความเย็นเพิ่มสูงขึ้น

มาตรการป้องกันความเสียหายจากสิ่งแวดล้อม

ขั้นตอนการป้องกันที่ดำเนินการเพื่อป้องกันการสึกหรอจากสิ่งแวดล้อม มักจะช่วยยืดอายุการใช้งานของคอนเดนเซอร์กระแสสลับ (AC condenser) ได้อย่างมาก การสวมปลอกหุ้มเมื่อระบบไม่ได้ใช้งาน จะช่วยปกป้องอุปกรณ์ให้ปลอดภัยจากหิมะในฤดูหนาวและฝนตกหนักในฤดูร้อน ซึ่งอาจก่อให้เกิดความเสียหายได้ ทางเลือกในการจัดภูมิทัศน์ก็มีความสำคัญเช่นกัน การจัดระบายน้ำให้ไหลออกจากตำแหน่งที่คอนเดนเซอร์ตั้งอยู่ ช่วยป้องกันไม่ให้อุปกรณ์ต้องรับภาระเกินความจำเป็น จากการรายงานของอุตสาหกรรมแสดงให้เห็นถึงประโยชน์ที่เกิดขึ้นจริงในโลกแห่งความเป็นจริง เมื่อมีการรักษาการป้องกันที่เหมาะสมเป็นระยะเวลานาน ผลลัพธ์ที่ได้คือ คอนเดนเซอร์ทำงานได้อย่างมีประสิทธิภาพเป็นเวลานาน แม้อากาศจะเปลี่ยนแปลงตามธรรมชาติอย่างไรก็ตาม

ข้อพิจารณาในการเปลี่ยนอะไหล่โดยผู้เชี่ยวชาญ

การเลือกเครื่องควบแน่นใหม่ให้ตรงกับกำลังการผลิตของระบบ

การเปลี่ยนตัวควบแน่นระบบปรับอากาศ (AC condenser) จำเป็นต้องเลือกให้เหมาะสมกับความสามารถของระบบอย่างถูกต้อง หากระบุขนาดความเย็น (tonnage) ผิดพลาด ปัญหาจะตามมาอย่างรวดเร็ว ระบบอาจเกิดอาการสตาร์ท-ดับ บ่อยครั้ง (short cycle) หรือไม่สามารถทำความเย็นได้เพียงพอ ซึ่งเป็นการสิ้นเปลืองพลังงานไฟฟ้าและเพิ่มแรงกดดันกับชิ้นส่วนต่างๆ ของระบบ ปัญหาลักษณะนี้จะส่งผลให้ค่าไฟฟ้าเพิ่มสูงขึ้น และทำให้อายุการใช้งานของชิ้นส่วนลดลงมากกว่าที่ควรจะเป็น นี่จึงเป็นเหตุผลว่าทำไมการทำงานร่วมกับช่างเทคนิค HVAC ที่มีประสบการณ์จึงมีความสำคัญ เพราะพวกเขาสามารถคำนวณความต้องการของพื้นที่ได้อย่างแม่นยำ และแนะนำหน่วยอุปกรณ์ที่ตรงกับข้อกำหนดเหล่านั้น การทำให้ถูกต้องตั้งแต่แรกจะช่วยให้ประสิทธิภาพโดยรวมดีขึ้น และลดปัญหาอุณหภูมิที่เปลี่ยนแปลงขึ้นลงไม่คงที่ภายในบ้าน

ความสำคัญของการติดตั้งโดยช่างเทคนิคที่ได้รับการรับรอง

การติดตั้งคอยล์เย็นของระบบปรับอากาศใหม่ให้ถูกต้องมีความสำคัญมากต่ออายุการใช้งานและประสิทธิภาพการทำงาน ดังนั้นการเลือกผู้ที่มีความรู้และประสบการณ์จึงมีความสำคัญอย่างยิ่ง ช่างที่ได้รับการรับรองจะมีความเข้าใจในข้อกำหนดตามมาตรฐานอุตสาหกรรมและแนวทางปฏิบัติที่เหมาะสม ซึ่งช่วยป้องกันข้อผิดพลาดในระหว่างการติดตั้งที่อาจทำให้การรับประกันในอนาคตเป็นโมฆะ ผู้ผลิตอุปกรณ์ส่วนใหญ่กำหนดให้ต้องมีหลักฐานการติดตั้งโดยบุคคลที่มีคุณสมบัติเหมาะสมก่อนที่จะให้การรับประกันอย่างเป็นทางการ การเลือกใช้บริการช่างที่ได้รับการรับรองไม่ใช่เพียงแค่การปฏิบัติตามข้อกำหนดเท่านั้น แต่ยังช่วยปกป้องปัญหาที่อาจเกิดขึ้นในอนาคตและรักษาสิทธิ์การรับประกันไว้เมื่อพบปัญหาในระยะยาว

ข้อกำหนดเกี่ยวกับการรับประกันสำหรับชิ้นส่วนที่อัปเกรดแล้ว

เมื่อพิจารณาอัปเกรดชิ้นส่วน การตรวจสอบรายละเอียดการรับประกันมีความสำคัญอย่างมากต่อการตัดสินใจอย่างชาญฉลาด เงื่อนไขการรับประกันแตกต่างกันอย่างมากระหว่างแบรนด์ต่าง ๆ ดังนั้นการเลือกผิดอาจทำให้ต้องเสียค่าใช้จ่ายเพิ่มเติมในอนาคตเมื่อระบบเริ่มเสื่อมสภาพ บางบริษัทมีการเสนอระยะเวลารับประกันที่ยาวนานขึ้นสำหรับรุ่นที่มีประสิทธิภาพการใช้พลังงานสูง ซึ่งอาจเป็นทางเลือกที่น่าสนใจหากผู้ซื้อต้องการสินค้าที่ใช้งานได้นาน การใช้เวลาเปรียบเทียบข้อเสนอการรับประกันเหล่านี้จะช่วยให้เข้าใจได้ว่าอะไรคือทางเลือกที่ดีที่สุด ซึ่งจะนำไปสู่การเลือกชิ้นส่วนที่ไม่เพียงแต่ทำงานได้ดี แต่ยังทนทานต่อการใช้งานเป็นประจำในระยะยาวหลายปี

คำถามที่พบบ่อย

เครื่องควบแน่นกระแสสลับ (AC condenser) โดยทั่วไปมีอายุการใช้งานกี่ปี

เครื่องควบแน่นกระแสสลับส่วนใหญ่ได้รับการออกแบบให้มีอายุการใช้งานระหว่าง 12 ถึง 15 ปี ขึ้นอยู่กับรูปแบบการใช้งานและการบำรุงรักษา

อาการที่บ่งชี้ว่าเครื่องควบแน่นกระแสสลับของฉันจำเป็นต้องเปลี่ยนคืออะไร

อาการหลัก ๆ ได้แก่ การทำความเย็นได้ไม่เพียงพอ รั่วของสารทำความเย็นที่แก้ไม่หาย เสียงที่ผิดปกติขณะทำงาน และการกัดกร่อนหรือความเสียหายของคอยล์ที่มองเห็นได้

ฉันจะยืดอายุการใช้งานของเครื่องควบแน่นกระแสสลับได้อย่างไร

การบำรุงรักษาอย่างสม่ำเสมอ เช่น การทำความสะอาดคอยล์ การตรวจเช็กโดยผู้เชี่ยวชาญ และการป้องกันความเสียหายจากสิ่งแวดล้อม เป็นกลยุทธ์ที่มีประสิทธิภาพ

ฉันควรคำนึงถึงอะไรบ้างเมื่อตัดสินใจเปลี่ยนเครื่องควบแน่นของเครื่องปรับอากาศ (AC condenser)

ประเด็นสำคัญที่ควรพิจารณา ได้แก่ การวิเคราะห์ต้นทุนโดยใช้กฎ 5,000 (5,000 Rule) ความคุ้มค่ากับอายุการใช้งาน และผลกระทบต่อสิ่งแวดล้อมจากประเภทของสารทำความเย็น

สารบัญ

- โดยทั่วไป เครื่องปรับอากาศแบบ AC ความ คาดหวัง ใน ชีวิต

- สัญญาณสำคัญที่บ่งชี้ว่าคุณต้องเปลี่ยนคอยล์คอนเดนเซอร์ของเครื่องปรับอากาศ

- ปัจจัยที่เร่งการสึกหรอของชุดควบแน่น

- กรอบแนวทางการตัดสินใจระหว่างซ่อมแซมกับเปลี่ยนใหม่

- กลยุทธ์การบำรุงรักษาเพื่อยืดอายุการใช้งานคอนเดนเซอร์

- ข้อพิจารณาในการเปลี่ยนอะไหล่โดยผู้เชี่ยวชาญ

- คำถามที่พบบ่อย