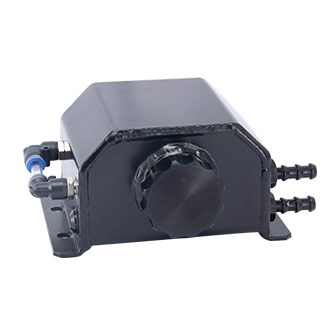

hjulnav assy

Hjulaksassemonteringen fungerer som et avgjørende komponent i moderne kjøretøy, og virker som den sentrale forbindelsespunktet mellom hjulet og kjøretøyets suspensjonssystem. Dette sofistikerte komponentet integrerer flere funksjoner i en enkelt enhet, inkludert skjelettstøtte, hjulmontering og roterende evne. Monteringen består av nøyaktig utformede skjær, segl, sensorer og monteringsflater som samarbeider smertefritt for å sikre optimalt hjulytelse og kjøretøyssikkerhet. Moderne hjulaksassemonteringer er designet med avanserte materialer og produksjonsteknikker for å gi utvidet tjenesteliv og pålitelig drift under ulike kjøreforhold. Integrasjonen av ABS-sensorer i mange samtidsmonteringer gjør det mulig å ha kritiske sikkerhetsfunksjoner og forbedret kjøretøykontrollsystemer. Disse monteringene er designet for å opprettholde riktig hjuljustering, redusere friksjon og støtte kjøretøyets vekt mens de lar hjulene rotere glatt. Designet inneholder spesifikke trekk for å forhindre forurensning og opprettholde riktig oljeføring, for å sikre langleiende ytelse og konsekvent ytelse. Avansert segleteknologi beskytter interne komponenter mot miljøfaktorer som vann, støv og veideponer, mens nøyaktige produksjonsavvik sikrer optimal skjærforspenn og minimal vibrasjon under drift.