Suprantimas Perkrovos bakas 's vaidmuo variklio aušinimo sistemose

Slėgio reguliavimas ir terminis stabilumas

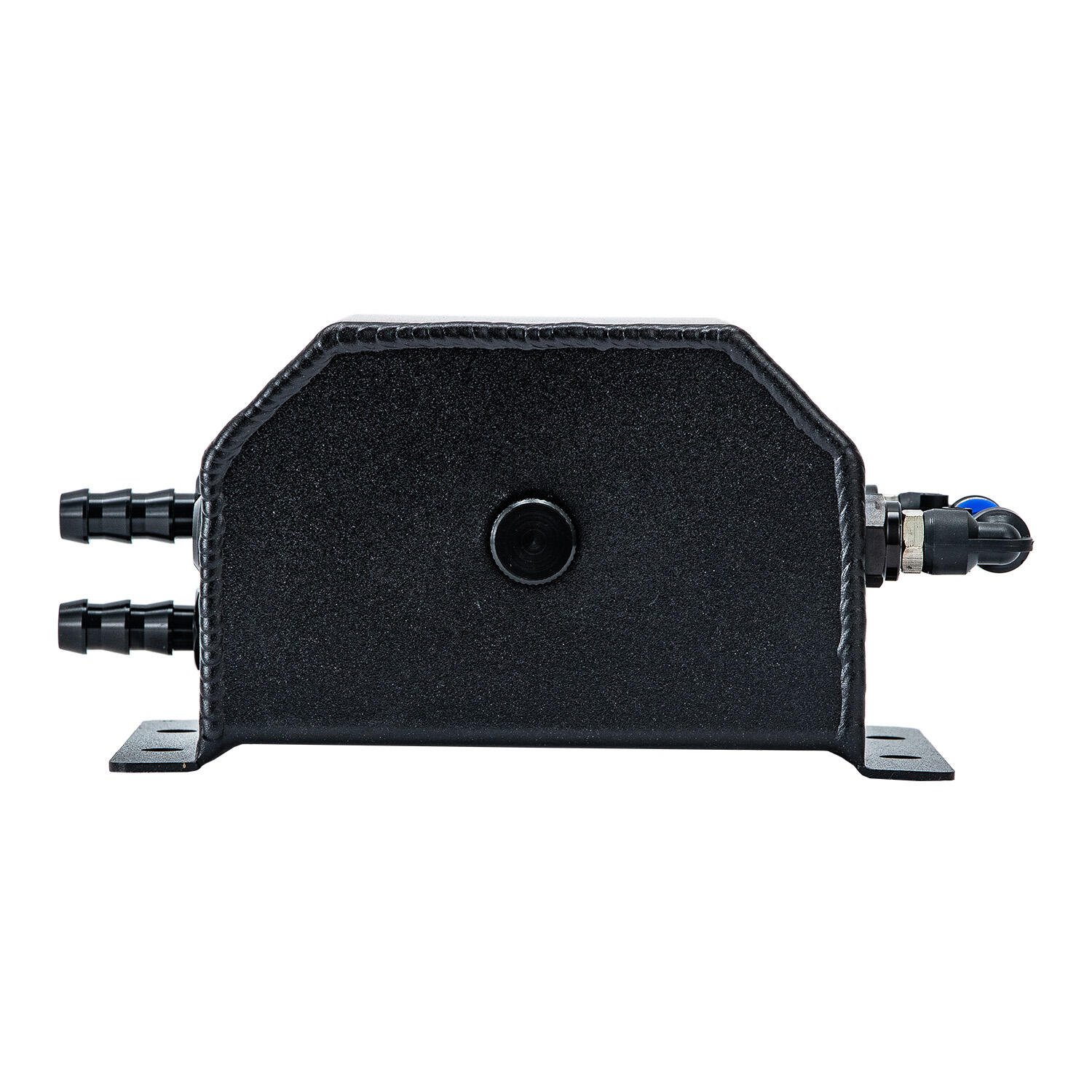

Aštuonkampis bakas yra labai svarbus, kad būtų išlaikytas slėgio lygis variklio aušinimo sistemoje. Į jį galima žiūrėti kaip į slėgio vožtuvą, kuris neleidžia viskam sutrikti, kad dalys neperkrautų jų ribų. Tyrimai parodė, kad šie slėgio valdymo mechanizmai iš tikrųjų pagerina variklio gebėjimą valdyti šilumą, o tai reiškia mažesnį judančių dalių nubrozdinimą ir geresnį bendrą našumą. Tada, kai aušinimo skysčio slėgis yra tinkamai reguliuojamas, varikliai dažniausiai veikia esant optimaliai temperatūrai. Toks nuolatinis veikimas yra svarbus siekiant, kad variklis ilgiau tarnautų ir efektyviau veiktų kasdien.

Aušinimo skysčio plėtimosi ir susitraukimo valdymas

Perkrovos bakas atlieka svarbų vaidmenį, kai vanduo plinta, ir užkertamas kelias nepageidaujamam išliejimui, kai variklis įkaito. Kai temperatūra pakyla, aušintuvas natūraliai išsiplėčia, o perteklinis rezervuaras veikia kaip atsargos vieta, kur saugomas visas papildomas skystis, kol jis neišlieja. Kai variklis vėl atvėsia, saugomas aušinimo tirpalas per specialius vožtuvus grįžta į sistemą. Tai neleidžia radiatoriui susidaryti oro kišenų, kurios sutrikdytų tinkamą kraujotaką. Mechanikai ne kartą pastebėjo, kad varikliai, kurių pertekliniai rezervuarai veikia tinkamai, veikia sklandžiau ir karštomis vasaros dienomis, ir šalčiomis žiemos rytą. Jei šaldymo sistema bus pasirengusi bet kam kitam, tai sumažins gedimus kelyje ar darbo vietose, kur darbo laikas kainuoja daug pinigų.

Oro patekimo prevencija uždarose sistemose

Perpylimo bakai atlieka daugiau nei tik saugo perteklinį aušinimo skystį – jie iš tikrųjų neleidžia orui patekti į sistemą, o tai gali sukelti garų blokavimo problemas ir sutrikdyti variklio aušimo efektyvumą. Kai oras pateks į sistemą, jis efektyviai blokuoja tinkamą aušinimo skysčio cirkuliaciją, dėl ko kyla perkaitimo situacijos, galinčios rimtai sugadinti variklio komponentus. Dauguma meistrų automobilių savininkams rekomenduoja reguliariai tikrinti bako sandarinimo būklę, nes net maži įtrūkimai ar prasti sujungimai leidžia orui prasiskverbti į vidų ir vėliau kelti įvairių problemų. Taip pat logiška per techninės priežiūros procedūras apžiūrėti perpylimo baką, nes ankstyva mažų problemėlių diagnostika užtikrina geresnį aušinimo našumą. Šios detalės priežiūra – tai ne tik geras įprotis, bet ir būdas sutaupyti lėšų ilgalaikėje perspektyvoje, užtikrinant sklandžią variklio veiklą be netikėtų gedimų.

Kaip veikia perpylimo bakas: aušinimo skysčio ciklas paaiškintas

Šalto variklio būklė: Pradinis aušinimo skysčio lygis

Kai variklis yra šaltas, perpylimo bakas iš tikrųjų atlieka gana svarbų darbą – jis palaiko tinkamą aušinimo skysčio lygį, kad variklis būtų apsaugotas jau nuo paleisties. Jei aušinimo skystis tinkamai cirkuliuoja, tam tikros variklio dalys perkaista, o tai gali sukelti įvairių problemų ateityje. Įsivaizduokite tokią situaciją: jei aušinimo skysčio lygis nukrinta žemiau reikalingo, svarbūs variklio komponentai nebeužpildomi tinkamai. Tai reiškia, kad variklis veikia karštesnis nei įprastai, o tai galiausiai reikalauja brangių remonto darbų. Pagal įvairius automobilių pramonės tyrimų rezultatus, vairuotojai, kurie nepaiso aušinimo skysčio lygio paleisdami variklį, dažnai susiduria su rimtomis variklio problemomis vėliau. Taigi, palaikyti tinkamą aušinimo skysčio lygį reikia ne tik šiltam varikliui – tai svarbu net tada, kai viskas dar yra šalta.

Šiluminio plėtimosi fazė: perteklinio aušinimo skysčio kaupimas

Kai variklis veikia ir aušinimo skystis pradeda kaiti, įvyksta natūralus išsiplėtimas. Čia į žaidimą įžengia perteklinio skysčio bakelis, kuris laiko papildomą aušinimo skystį, kai temperatūra pakyla, išlaikant viską subalansuotą aušinimo sistemoje. Be tinkamos talpos, varikliai greitai perkaistų. Todėl šie bakeliai yra labai svarbūs, kad būtų užtikrinta stabili veikla normaliomis sąlygomis. Tinkamai veikiantis perteklinio skysčio bakelis iš tikrųjų apsaugo kritiškai svarbias variklio dalis nuo pažeidimų, ypač kai transporto priemonės ilgą laiką eksploatuojamos arba karštomis dienomis, kai mechaninių sistemų apkrova smarkiai padidėja.

Aušinimo skysčio grąžinimas temperatūrai krintant

Kai varikliai atvėsta po karšto bėgimo, perpildymo bakas svarbiai prisideda prie aušinimo skysčio grąžinimą į pagrindinę sistemą. Tai padeda išlaikyti pusiausvyrą ir užtikrina geresnį variklio veikimą. Visa sistema veikia kartu, kad užtikrintų sklandžią veiklą, o tai faktiškai taip pat padeda sutaupyti kuro išlaidų, nes aušinimo sistema tinkamai funkcioniškai veikia. Meistrai iš patirties žino, kad stebėti, kaip aušinimo skystis grįžta į sistemą, yra labai svarbu ilgaamžiškumui. Be šio grįžtamąjį srautą, aušinimo kanaluose gali susidaryti oro burbulai. Šie oro kištukai sukelia problemas, nes trukdo tinkamam aušinimo skysčio cirkuliavimui, dėl ko gali įvykti perkaitimas ir ilgainiui galimas pažeidimas. Todėl reguliariai atlikti priežiūros patikras yra itin svarbu automobilio savininkams, kurie nori, kad jų variklis tarnautų ilgiau.

Perpildymo bako našumo poveikis variklio temperatūrai

Šilumos sklaidos efektyvumas

Kai perpylimo bakas veikia tinkamai, jis padeda pašalinti perteklinę šilumą, o tai yra labai svarbu varikliams veikti optimaliai. Tyrimai rodo, kad automobiliai, kurių perpylimo bakai yra gerai prižiūrimi, visapusiškai veikia vėsiau. Temperatūros sumažėjimas reiškia, kad variklis veikia sklandžiau, o tai mažina apkrovą ant visų vidinių metalinių dalių. Mažesnė apkrova reiškia mažiau gedimų ateityje, todėl variklis tarnauja ilgiau ir išlieka patikimas metų, o ne mėnesių bėgyje.

Palaikyti optimalų aušinimo skysčio kiekį

Perpylimo bakai svarbiai prisideda prie optimalaus aušinimo skysčio kiekio palaikymo, o tai daro įtaką variklio veikimui eksploatacijos metu. Kai per aušinimo sistemą cirkuliuoja per mažai skysčio, varikliai greitai perkaista, o tai kartais sukelia rimtus vidinių dalių pažeidimus. Meistrai dažnai rekomenduoja tikrinti aušinimo skysčio lygį bent kartą per mėnesį arba kas du mėnesius kaip dalį kasdieninės automobilio priežiūros. Pagal naujausius šaltinius, gautus iš Šiaurės Amerikos automobilių remonto asocijacijų, automobiliai, kurių aušinimo sistemos tinkamai prižiūrimos, paprastai sunaudoja 8–10 % mažiau kuro lyginant su automobiliais, kurių sistemos nebuvo prižiūrimos. Be to, tokie automobiliai tada tarnauja ilgiau iki kapitalinio remonto. Todėl ne užmirškite retkarčiais pažvelgti po kapotu ir užtikrinti, kad tiek perpylimo bakas, tiek pagrindinis aušinimo skysčio rezervuaras būtų tinkamai užpildyti, kad variklis ilgą laiką veiktų patikimai ir efektyviai.

Slėgio disbalanso poveikis

Kai automobilio aušinimo sistemoje susidaro nevienodas slėgis, tai labai trikdo variklio tinkamo temperatūros palaikymą. Čia pagalba atsiranda perpylimo bakelis. Jis padeda sugerti tuos slėgio svyravimus, kad variklis veiktų sklandžiau. Meistrai tai mato gana dažnai – automobiliai, kuriuose yra blogų slėgio problemų, greičiau praryja dalis nei įprasta. Radiatoriaus žarnos greičiau tampa trapios, vandens siurbliai sugenda anksčiau, o kartais net galvutės tarpinė pradeda leisti. Tačiau tinkamai veikiantis perpylimo bakelis padeda ne tik išvengti gedimų. Veikiantis bakelis reiškia, kad variklis ilgiau tarnauja tarp kapitalinio remonto ir kasdien geriau dirba be netikėtų problemų.

Neveikiančio perpylimo bako pasekmės

Perkaitimo rizika dėl aušinimo skysčio praradimo

Netinkamai veikiantys perteklių bakai gali rimtai sugadinti automobilį, ypač todėl, kad leidžia aušinimo skysčiui išsiveržti. Jei šis bakas netinkamai atlieka savo funkciją – kaupia ir grąžina aušinimo skystį – ilgainiui bus patiriamos rimtos aušinimo skysčio nuostatos. Ir ką tai reiškia? Variklis pradės perkaisti, o tai yra viena pagrindinių priežasčių, kodėl varikliai anksčiau laiko išeina iš rikiuotės. Meistrai dažnai susiduria su atvejais, kai automobiliai praranda aušinimo skystį ir dėl to susidaro perkaitimo problemų. Reguliarios perteklių bako apžiūros yra labai svarbios, kad viskas veiktų sklandžiai. Užtikrinus, kad ši dalis veiktų tinkamai, galima išvengti nelemtų perkaitimo atvejų ir ilgiau išlaikyti variklio sveikatą tarp remontų.

Slėgio šuoliai ir apkrauti komponentai

Kai perpylimo bakas pradeda veikti netinkamai, automobilio aušinimo sistemoje kyla slėgio šuoliai, kurie sukelia didelę įtampą svarbiems variklio komponentams. Kintamas slėgis dažnai sukelia išsilydžiusias tarpines arba išlinkusius cilindrų galvutes, o tai reiškia brangius vizitus pas mechaniką. Tokią situaciją mechanikai mato nuolat dirbdami su variklių gaubtais. Gerai veikiantis perpylimo bakas užtikrina stabilų slėgį visoje sistemoje. Toks stabilumas yra svarbus, nes nuolatiniai slėgio pokyčiai pamažu dėvi komponentus, kol galiausiai viskas visiškai sugenda. Reguliariai tikrinant ir prižiūrint perpylimo baką, bet kas, norintis ilgiau išlaikyti be sutrikimų veikiantį variklį ir išvengti netikėtų gedimų, kurie vėliau kainuotų tūkstančius, tai yra protingas sprendimas.

Oro kišenės, mažinančios aušinimo galimybes

Kai perpylimo bakelis veikia netinkamai, jis leidžia susidaryti oro burbulams aušinimo sistemoje, dėl ko smarkiai mažėja jos aušinimo efektyvumas. Oro sistemoje trikdo tinkamą šilumos perdavimą, todėl variklis veikia karštesnis nei turėtų, o tai gali sukelti rimtas problemas ateityje. Perpylimo bakeliai iš tikrųjų atlieka svarbų vaidmenį, kad nepageidaujami oro maišai susidarytų ir viskas išliktų pakankamai aušta. Visi mechanikai, kuriems rūpi, sako, kad reguliariai tikrinti ir prižiūrėti perpylimo bakelį yra verta daugiau nei savo svorio aukse. Palaikant šią detalę geroje būklėje užtikrinamas geresnis šilumos valdymas ir mažesnė perkaitimo problemų rizika, ko tikisi kiekvienas automobilio savininkas.

Perpylimo bako priežiūros geriausios praktikos

Vizualinė apžiūra dėl įtrūkimų/įlūžių

Labai svarbu reguliariai tikrinti skysčių išplėtimo bakelį, ar jame nėra įtrūkimų ar nutekėjimų, jei norime, kad jis toliau tinkamai veiktų. Dauguma mechatronikos meistrų pasakys, kad svarbu užkirsti kelią šiems nesklandumams dar prieš prasidedant didesnėms problemoms – tai ilgainiui sutaupys pinigų. Kai kurios studijos rodo, kad mažų nutekėjimų aptikimas laiku gali iš esmės padvigubinti visos aušinimo sistemos tarnavimo laiką. Jei yra įtrūkimų ar nutekėjimų, baks tiesiog negali tinkamai atlikti savo funkcijos – kontroliuoti aušinimo skysčio lygio, o tai veda įvairias problemas, įskaitant variklio perkaitimą. Taigi, praleisti kelias minutes kartais pažiūrėti į šią detalę yra prasmė visiems, kurie nori, kad jų automobilis patikimai veiktų ir netrukdytų netikėtomis gedimų situacijomis.

Aušinimo skysčio lygio stebėjimo technikos

Stebėti aušinimo skysčio lygį yra labai svarbu, jei norime, kad mūsų variklis veiktų sklandžiai ir būtų išvengta nemalonių perkaitimo situacijų. Daugelis žmonių naudoja arba žymiklio tyrimą, arba tam tikrą plūdų matuoklį, kad geriau suprastų, kas vyksta viduje. Abu metodai veikia gana gerai, jei yra tinkamai atliekami. Meistrai paprastai rekomenduoja šiuos lygius tikrinti bent kartą per mėnesį atliekant standartinę priežiūrą. Nuoseklus dėmesys šiai paprastai užduočiai padeda išlaikyti tinkamą aušinimo funkciją, todėl žymiai sumažėja galimų variklio problemų ateityje.

Kada keisti kritines komponentas

Pakeičiant pagrindines dalis, tokias kaip pertekliaus bakas, laiku užtikrina visa sistema tinkamai veikia. Atkreipkite dėmesį į požymius, kurie pasirodo per planines apžiūras – korozijos žymės, įtrūkimai ar bet koks fizinis pažeidimas, kurie signalizuoja, kad atėjo laikas keisti dalį. Meistrai iš patirties žino, kad vėluojant pakeisti šias dalis dažnai kyla dar didesnių problemų ateityje, susijusių su aušinimo sistema. Mažos išlaidos dabar padės išvengti brangių remontų vėliau. Varikliai veikia sklandžiau ir ilgiau, kai priežiūra atliekama proaktyviai, o ne laukiant, kol kažkas visiškai suges.

Perpylimo bakas kontra išplėtimo bakas: pagrindiniai skirtumai

Slėgio sistemos skirtumai

Žinant, kaip skirtingai veikia slėgis pertekliaus ir plėtimosi bakų sistemose, tinkamai priežiūrėjant transporto priemones, tai turi didelės reikšmės. Pertekliaus bakai paprastai veikia esant daug mažesniam slėgiui nei plėtimosi bakai, o tai daro įtaką jų funkcijoms ir vietoms, kur jie naudojami. Šis skirtumas yra svarbus. Automobilių vadovai pabrėžia, kad šių dviejų tipų sumaištis gali sukelti rimtų problemų ateityje. Pertekliaus bakai dažnai turi specialius kamščius, kurie leidžia jiems valdyti perteklinę garą ir aušinimo skystį, neleidžiant susidaryti per dideliam slėgiui. Plėtimosi bakai veikia kitaip – jie nuolat palaiko slėgį, grąžindami aušinimo skystį atgal į variklį kiekvieną kartą, kai veikiant sistemai reikia papildomo skysčio.

Aušinimo skysčio cirkuliacijos mechanizmai

Perpylimo ir plėtimosi bakai veikia visai skirtingai, kai reikia cirkuliuoti aušinimo skystį, o tai daro įtaką variklio aušinimo kokybei. Plėtimosi bakai leidžia įkaitusį aušinimo skystį vėl grįžti į sistemą po to, kai jis išsiplėtė, o perpylimo bakai tiesiog laiko papildomą skystį, kol jis vėl prireiks. Dėl šio konstrukcijos skirtumo, plėtimosi bakai veikia efektyviau, nes nuolat judina aušinimo skystį per visą sistemą, neleisdami jam stovėti. Meistrai, dirbę su įvairiomis transporto priemonėmis, žino, kad tai ypač svarbu derinant našumą esant skirtingoms sąlygoms. Tačiau tai, kas tikrai išskiria plėtimosi bakus – tai jų gebėjimas susidoroti su slėgio šuoliais, atsirandančiais intensyviai pagreitinus ar važiuojant į kalną. Žinoma, jų įdiegimas ir priežiūra yra sudėtingesnė lyginant su paprastesnėmis perpylimo konstrukcijomis, tačiau automobiliams, reikalaujantiems maksimalios aušinimo galios, tokiems kaip lenktynių automobiliai ar sunkieji sunkvežimiai, papildoma sudėtingumo dalis atsiperka patikimumo ir temperatūros valdymo požiūriu.

PROGRAMA -Specifinės dizaino savybės

Perpylimo ir plėtimo bakų dizainas keičiasi priklausomai nuo jų funkcijų automobilyje. Kai kurie varikliai reikalauja specialių savybių dėl jų konkrečių reikalavimų. Paimkime, pavyzdžiui, aukšto našumo variklius – dažnai reikia stipresnių sistemų, kad galėtumą atlaikyti jų darbo apkrovas. Iš praktikos matėme, kad kai bako dizainas gerai atitinka variklio technines charakteristikas, visa sistema veikia geriau. Teisingas sprendimas leidžia automobilio aušinimo sistemai veikti taip, kaip numatyta, todėl tinkamo bako pasirinkimas yra labai svarbus skirtingiems automobilių modeliams. Žinios apie tai, kaip šie bakai skiriasi, nėra tik akademinės žinios – jos leidžia pasirinkti tarp patikimai kasdien veikiančios aušinimo sistemos ir tokios, kuri netikėtai sugenda.

D.U.K.: Pertekliniai bakai ir aušinimo našumas

Perteklinio bako gedimo požymiai

Žinoti, kada sugenda perpylimo bakas, yra labai svarbu, kad variklis tinkamai veiktų. Atkreipkite dėmesį į tokius dalykus kaip aušinimo skysčio lašėjimas iš bakelio arba jo lygio svyravimai. Bakuose, kuriuose atsiranda įtrūkimų, dažnai stipriai nuteka ir visa aušinimo sistema dirba sunkiau nei turėtų. Meistrai visada pataria klientams išspręsti šias problemas iš karto, nes jas pašalinus ankstyvai, ateityje sutaupoma pinigų ir bėdų. Pagal faktines remonto dirbtuvių duomenis, automobiliai, kurių savininkai iš karto reagavo į pirmus problemas, turėjo daug mažiau rimtų variklio gedimų nei tie, kuriuos ignoravo iki visiško sugedimo.

Kuro sąnaudų efektyvumo poveikis

Gerai veikiantis skysčių pertekliaus bakas leidžia automobiliui geriau vartoti degalus. Kai aušinimo skystis išlaikomas reikiamame lygyje, variklis dirba ne taip sunkiai, todėl, kaip pastebi meistrai, padidėja mylių skaičius vienu degalų litru. Užpildžius aušinimo skysčio lygį, variklis perkaista mažiau, todėl veikia sklandžiau ir sunaudoja mažiau degalų. Daugelis vairuotojų apie pertekliaus bakus nedaug galvoja, kol neiškyla problema, tačiau reguliariai atliekami patikrinimai padeda ilgiau išlaikyti automobilio geresnį darbą ir ilgainiui sutaupyti degalų.

Suderinamumas su skirtingų tipų skysčiais

Skirtingos perpildymo talpos veikia geriau su konkrečiais aušinimo skysčiais, todėl svarbu pasirinkti tinkamą talpą, kad visa sistema veiktų kuo geriau. Aušinimo skysčių gamintojai įspėja, kad netinkama formulė gali pamažu ardyti talpos medžiagą, galiausiai sukeldama nutekėjimą ar net visišką sugedimą. Kai žmonės skiria laiko patikrinti aušinimo skysčio suderinamumą, jie padeda sistemai ilgiau veikti be pertrūkių. Toks dėmesys detalėms užtikrina, kad aušinimo sistema veiktų geriausiai ir pratęstų transporto priemonės gyvavimo laiką, išvengiant nereikalingų problemų ateityje.

Turinio lentelė

- Suprantimas Perkrovos bakas 's vaidmuo variklio aušinimo sistemose

- Kaip veikia perpylimo bakas: aušinimo skysčio ciklas paaiškintas

- Perpildymo bako našumo poveikis variklio temperatūrai

- Neveikiančio perpylimo bako pasekmės

- Perpylimo bako priežiūros geriausios praktikos

- Perpylimo bakas kontra išplėtimo bakas: pagrindiniai skirtumai

- D.U.K.: Pertekliniai bakai ir aušinimo našumas