ჰაერის ზეთით გაგრილებული ძრავა

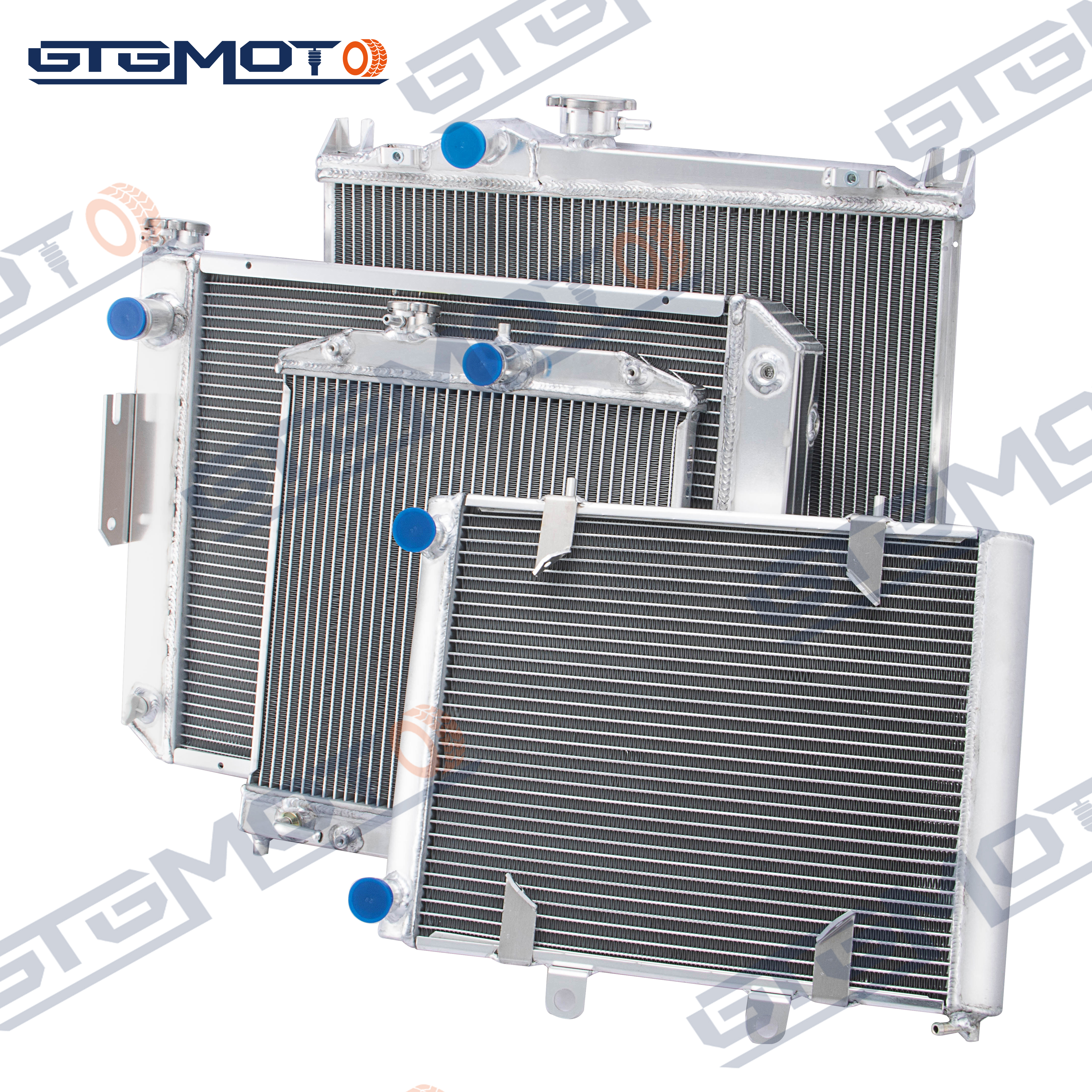

Ჰავა-ოილ გამყარებული მძღოლი წარმოადგენს სოფელს ჰიბრიდულ გამყარების სისტემას, რომელიც შე祺ავს ჰავა და ოილის გამყარების ტექნოლოგიების საუკეთესო მხარეებს. ეს ინოვაციული სისტემა გამოიყენება ჰავასა და ოილის შემთხვევაში, რათა ეფექტურად რეგულირებინა მძღოლის ტემპერატურა, უზრუნველყოფს მაქსიმალურ მუშაობასა და გარჩევას. მძღოლი იყენებს ფინებისა და გამყარების ქსელს, სადაც ოილი ცირკულირება მძღოლის ბლოკში, გადაიღებს სიცივს კრიტიკული ელემენტებიდან. ერთდროულად, გარე ჰავის მარაგი სPECIALლ დამზადებულ გამყარების ფინების მიერ დახარჯდება ატმოსფერაში. ოილი სამუშაოს ერთადერთი მიზანია: ის გამოიყენება მოძრაობის ნაწილების შეხებისთვის და გამყარების მთავარ საშუალების როლში. ეს დიზაინი განსაკუთრებით ეფექტურია სამუშაო ტემპერატურების ერთმანეთს მუშაობის გარანტირებით მძღოლის განსხვავებულ ელემენტებზე, რაც განსხვავდება ტრადიციული ჰავა-გამყარებული სისტემებისგან, რომლებიც შეიძლება გამოიყენონ არაერთობრივ გამყარება. სისტემა შეიცავს ოილის გამყარების მოდულს, რომელიც მუშაობს ოილის რადიატორის როლში, რათა გამყარების საშუალება მარტივად შეინარჩუნოს. გამოყენების საერთო მაგალითები შედგება მოტოციკლებს, მცირე ავიაციასა და ინდუსტრიულ მანქანებზე, სადაც გამოსადეგი და მარტივი მეცნიერება არის საჭირო. ტექნოლოგია გამოჩნდა განსაკუთრებით სამსახურში, სადაც წყლის გამყარების სისტემები შეიძლება იყოს არაპრაქტიკული ან სადაც წონის განსაზღვრება არის კრიტიკული.