Skilningur á loftneyslukerfi nútíma ökutækja

Bílagerðin hefur verið vitni um mikla þróun á loftneyslu tækni, sérstaklega í bifreiðum frá árinu 2025. Í hjarta þessa flókna kölukerfis er Stöðugleikaþjöppun aC-köndens, mikilvægur hluti sem breytir kæliefni úr gasi í vökva. Þegar vandamál koma upp við AC-köndens, geta þau alvarlega haft áhrif á kölunaraðstæður í ökutækinu og komfort farþega.

Nútímalegar bílar innihalda háþróaðar greiningarkerfi og snjallir nemi sem hjálpa til við að greina mögulegar vandamál áður en þau verða alvarleg. Þó er mikilvægt að skilja algengar merki og einkenni vandamála með loftskiptaþétta hjá öllum bílaeigendum. Þessi nýttileg leiðbeining mun fara yfir greiningarferlið skref fyrir skref og hjálpa þér að halda loftskiptakerfinu í bílnum þínum á bestu getu á árinu 2025.

Helstu hlutir í loftskiptakerfi hjá bílum

Hlutverk Stöðugleikaþjöppun

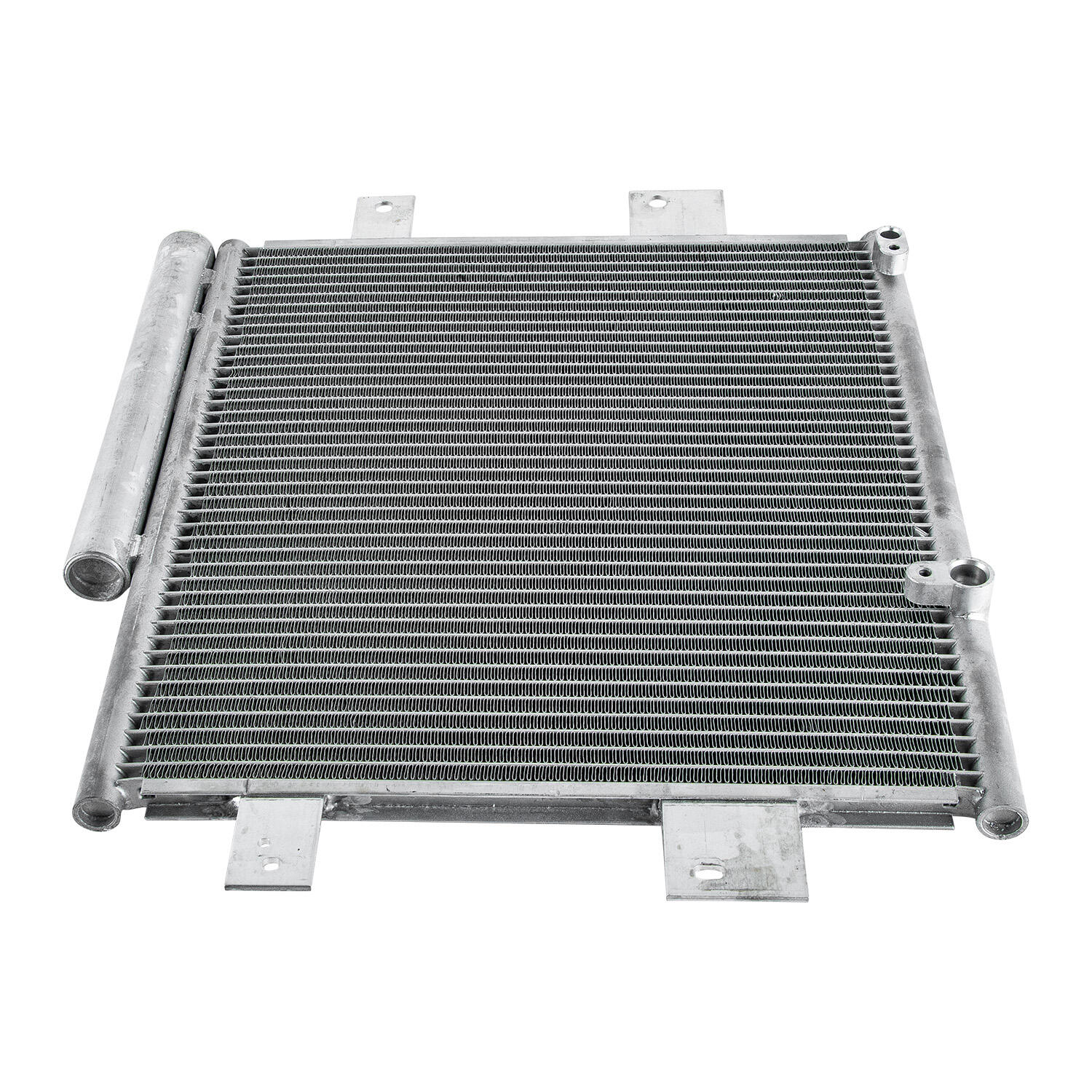

Loftskiptaþéturinn er helsti hitavexturinn í loftskiptakerfi bílsins. Hann er venjulega staðsettur fremst við hitaskiptavölvuna og hefur ábyrgð á mikilvægu verkefni þess að kæla og þétta kæliflokkshugmyndina yfir í vökvahugmynd. Í bílum árið 2025 eru þéturarnir búnir upp úr jafn betri eldnisgerð og fleiri samhverfum flæðisgöngum til að hámarka hitaflutningsefni.

Nútímalegar þéttingar innihalda einnig sameiginlega safnara og hluti til að undirhita, sem gerir þær minni en áður en samt sem áður hagkvæmari. Þessi framfarin hönnun gerir kleift að ná betri kólnunaraðgerð meðan viðhaldað er bræðlisöðruðum staðli.

Sameining við ræn bifreiðarkerfi

Nútímar bifreidar eru búðar við fljótbæra rafstýringarhluti sem stöðugt fylgjast með afkölnunarkerfið. Þessi ræn kerfi geta uppgötvaðar fínn breytingar á þrýsting, hitastig og flæði á kæliefni, og þar með gefið ávörun um mögulegar vandamál við afkölnunarkerfið áður en þau verða alvarleg. Með því að sameina þau við bifreiðarprófanir er hægt að skoða og vinna úr vandamálum nákvæmara og skipulegur.

Modellirnar fyrir 2025 innihalda einnig sérsniðin kölnunarreiknirit sem hægja á afkölnunarkerfinu eftir akstursáætlun, umhverfis hitastig og kölnunarþörfum. Þessi ræn nálgun gerir kleift að hámarka afkölnunarkerfið meðan forðast er óþarfa álagning á hlutum.

Algengar merki um vandamál við afkölnunarkerfið

Vísuell ábólgunartákn

Ytri skemmdir á kondensatorinum eru oftast hægt að sjá með nákvæmri vísuelri ábólgun. Leitið að merkjum um fyrirheitarskaða eins og fleygðum fýlum, safnunargagni eða augljósum leka á kælifri. Nútímakondensarar í bifreiðum árið 2025 eru með verndandi efni sem geta sýnt litabreytingar eða niðurbrotsmerki þegar þau eru skemmd.

Athugaðu hvort olíuflekkir eða afgangs efni séu á tengingum kondensatorsins, þar sem þetta bendir venjulega á brot í þéttunum eða smáleka. Ef rúst hefur myndast eða sýnast minerales efni gæti það bent á innri niðurbrot sem krefst sérfræðinga.

Ábólgunartengdar vandamál

Þegar bifreið hefur vandamál við AC-kondensatorinn, sýnist oftast ákveðin vandamál með afköst. Minskað kælingarafköst, sérstaklega við óhreyfða keyrslu eða í stöðugum umferðarstöðum, eru algeng tákn. Rafkrafstýrð loftslagakerfið gæti sýnt villukóða eða viðvörunarsemin í gegnum upplýsingatækjakerfið í bifreiðinni.

Hljóðaðu að óvenjulegum hljóðum á meðan A/C-kerfið er í starfi, svo sem sifranir eða skjálftir, sem gætu bent á að kæliflöðið sé að leka eða að hlutir séu lausir. Hægri hljóðfræði í nýjum bifreiðum getur hylt þessum hljóðum og því er mikilvægt að vera sérstaklega vartur við greiningu.

Framfarin greiningaraðferðir

Greining á rafkerfum

Nútímagreiningartæki geta tengst borðtölvu í bifreiðinni til að ná í nákvæmari upplýsingar um afköst. Þessi háþróaðu tæki veita rauntíma fylgni með mælingum á þrýstingi, hitastigabreytingum og sviði kæliflöðis. Módelin úr árinu 2025 eru með betri greiningarvélbúnað sem getur nákvæmlega greint villur í A/C-kerfinu.

Sérstök greiningartæki geta framkvæmt sjálfvirkar kerfisprófanir til að kanna hvort kerfið sé að virka rétt undir ýmsum starfsumstæðum. Þessi nálgun gerir kleift að greina vandamál með A/C-kælirann áður en kerfið missir öll sín afköst.

Þrýstingarpróf og uppgöngulokning

Nútímalegar aðferðir til að finna leka nota sér ljómandi blekja og rafsegulþenslunefni til að nákvæmlega greina vandamál. Þessi tæki geta fundið jafnvel minnstu leka sem ekki eru sýnilegir við venjulega yfirferð. Kæliflæðisvélar fyrir 2025 eru hönnuðar með þjónustuhylki sem auðveldar nákvæma þrýstingssköpun án þess að trufla kerfið.

Sérfræðingar geta framkvæmt þrýstingsmælingar til að meta heildarstöðugleika kerfisins yfir lengri tímabil. Þessi aðferð er sérstaklega skilvirk til að bera kennsl á millibilaleka eða hægan tap á kæliefni í gegnum mikrosmá bil.

Forskoðunarþjónustu Aðferðir

Regluleg kerfisinsýning

Að beita fyrbyggjandi viðgerðaskema hefur þá áhrif að koma í veg fyrir aðalvandamál með loftkælisspóla. Regluleg hreinsun á spólasvæði tryggir bestu varmaumfærslu og virkni kerfisins. Nútíma bifreiðum er beitt verndandi efnum sem verður að leka safnast ekki upp á, en regluleg yfirferð er ennþá nauðsynleg.

Heldu utan um kæliflöðs- og kerfisþrýsting á meðan þú framkvæmir venjulega viðgerð. Flínustuðlar í 2025 bifreiðum veita nákvæmar mælingar sem hjálpa til við að halda á bestu afköstum og koma í veg fyrir álagsáverka.

Framkvæmdaframkomulag

Venjulegar hugbúnaðsuppfærslur fyrir loftslagsstýringarkerfið tryggja bestu afköst og samhæfni við nýjari greiningarverkfæri. Þessar uppfærslur innihalda oft betri reiknirit fyrir kerfisstýringu og betri vernd gegn algengum vandamálum við AC kondensatora.

Litið til þess að nota hágæða kæliefni og smyrjiefni sem eru sérstaklega hannað fyrir nútímaleg AC kerfi. Þessi nýjungarefni veita betri varmaumfærsluefni og vernd á hlutum, sem lengur líftíma AC kondensatorsins.

Oftakrar spurningar

Hvenær ætti ég að láta þurfa bifreiðar loftslagskerfið mitt?

Árlega eða á hverjum 15.000 mílum ætti að láta skoða AC-kerfið af sérfræðingum, hvort sem kemur fyrst. Þó svo, geta 2025 bifreiðir sem eru búin við ræðan greiningarkerfi gefið til kynna að þörf sé á viðgerð eftir raunverulega afköst og notkunarmynstur kerfisins.

Hvað veldur vanstæðum í AC-kælirörum í nútíma bifreiðum?

Algeng orsök eru fyrirmyndleg áverka vegna vegfölls, efnafræðileg mengun kæliefnisins, gallar í rafkerfinu og náttúruleg níðingur á loku og tengingum. Samþætt hönnun nútímakæliróra þýðir að vanstæður í einni hluta geta oft krafststæðu um skiptingu um alla einingu.

Get ég keyrt áfram með vandamálum í AC-kælirörum?

Þótt bifreiðin þín haldi áfram að virka, getur notkun á vanstæðu AC-kerfi valdið alvarlegri skemmd og dýrum viðgerðum. Rafkerfi nútíma bifreiða geta sjálfkrafa óvirkjað AC-kerfið ef alvarleg vandamál í kælirörum eru greind til að koma í veg fyrir skemmd á hlutum.