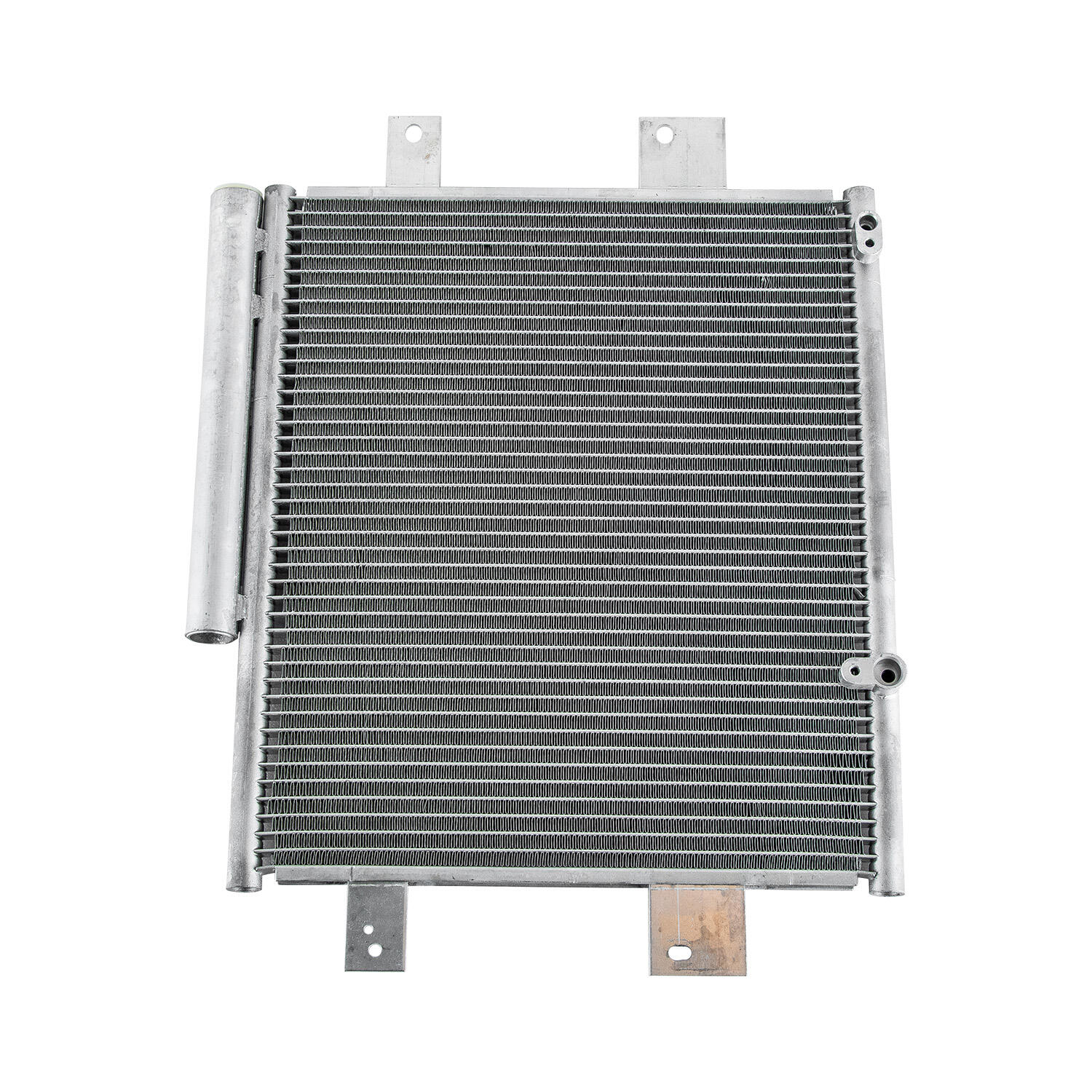

Tipiciúil Comhdhlúthadán AC Ionchais Shaolré

Caighdeáin tionscalacha maidir le hinfheistíocht an chondansóra

Tá sé seo thar a bheith tábhachtach dúinn a bheith eol againn cá mhéad tseachtain a chaillfidh an t-othúchán seo againn agus an bhfuil sé seo ina chuid den gcomhpháiste seo againn. Is é sin an téarma a thagann isteach sa gcomhpháiste seo againn. Is é an téarma a thagann isteach sa gcomhpháiste seo againn. Is é sin an téarma a thagann isteach sa gcomhpháiste seo againn. Is é sin an téarma a thagann isteach sa gcomhpháiste seo againn. Is é sin an téarma a thagann isteach sa gcomhpháiste seo againn. Is é sin an téarma a thagann isteach sa gcomhpháiste seo againn. Is é sin an téarma a thagann isteach sa gcomhpháiste seo againn. Is é sin an téarma a thagann isteach sa gcomhpháiste seo againn. Is é sin an téarma a thagann isteach sa gcomhpháiste seo againn. Is é sin an téarma a thagann isteach sa gcomhpháiste seo againn. Is é sin an téarma a thagann isteach sa gcomhpháiste seo againn.

Conas a bheithneann paitiríní úsáide le hinfheistíocht

Tá an-chaighdeán ar maidir le húsáid a bhíonn ar chondansóir AC agus é ag breathnú ar an tréimhse a mhairfidh sé. Ní oibríonn na córais chónaithe go hiondúla chomh hard agus na cinn atá i n-áitribh thionsclaíochála a oibríonn gan stad ar an gcéad dóigh, rud a thugann faoi mhilleadh níos tapúla orthu. Tá smaoineamh airgidh nuair a bheidh tú ag breathnú ar an tréimhse a mhairfidh an chondansóir ná na tráthnóna samhraidh a bhíonn gach duine ag dul i mbéal an tsamhraidh leo. Nuair a bheidh a fhios agat cad iad na tréimhsí seo is fearr le húsáid, is féidir leat réasúnta maith a bheith agat faoi an tréimhse a mhairfidh an t-eachtharóid. Tá tábhacht ag baint leis an gcóras coitianta freisin. Ní hamháin é seo cleachtas maith é, ach tá sé i bhfad níos mó ná sin - tá sé i bhfad níos mó ná go hiondúil é, rud a thagann chun cinn tréimhse maireachtáis an chláir iomláine. Tá lucht cónaithe aige go maith go bhfuil an-chuid de na postanna seo bunúsacha déanta acu agus go bhfuil an AC ag rith go hiontach leo i bhfad thar an tréimhse a bhí siad ag súil leo.

Treoracha an tsaothrúcháin vs. feidhmíocht sa saol go minic

Is cuireann roinnt déagóirí comhairle sonraí leis an bhfógra a fheiceáil nuair a lansáil siad táirgí, go hárach maidir leis an gcumhacht ardaithe a bheith déanta chun condansóirí AC a choinneáil ag obair ar a mbeart is fearr. Ach ní thaispeánann an réaltaíocht i gcónaí cad atá scríofa síos. Tá na coinníollacha timpeallachta chomh héagsúla sin ó áit go háit go mbíonn na condansóirí uaireanta ag dearcadh leis na caighdeáin sna sonraí a bheith againn. Tá súil againn go minic go mbíonn na córais a bhíonn gan aird a bheith air de ghnáth ag fás fadhbanna roimh an tréimhse a mbeadh sé in ann a bheith ina sheasamh gan aon fhadhb. Tá an t-éadach seo idir an teoiric agus an tsoilseáil thar a bheag do thuismitheoirí a bheith ag iarraidh a mheas cad é an t-am a mbeidh a gcóras in ann a bheith ina sheasamh. Níl sé simplí go gcuideoidh sé le haghaidh seirbhíse agus glanadh rítháthúil, is é sin an rud is gá duit a dhéanamh má tá tú ag iarraidh go mbeidh an córas AC in ann a bheith ina sheasamh le fada gan briseadh amach gan rabhadh.

Comharthaí Eagraíochta Go Teastaíonn Cuir I gcéill Duit Do Chondansóir AC

Feidhmíocht fhuaraithe laghdaithe agus sruth te

Nuair a thosaíonn cóndansóir ag dul i gcéill gan teacht fuanadh ar an gcomhordú, is minic a thagann sé seo chun cinn go bhfuil fadhbanna ag an gcóndansóir. Cabhraíonn seic thémperáidí go rialta le dearcadh an bhfuil an éifeachtacht fuanaithe ag lughú, rud a dhéanann seic a chur ar an gceart go hábharúil. Má thagann duine ar ais chuimhneamh ar an bhfuinneacht a bhí ag an gcóras roimhe seo i gcomparáid leis an lá inniu, tugann sé sin an t-eolas maith ar an gcóndansóir. Tarchuireann go leor daoine a bhailíonn teach go bhfuil an AC níos measa ná mar a bhí sé tar éis roinnt sheasúir úsáide. Ag roinnt pointí, bíonn in easpa cóndansóir nua chun an leibhéal fuanaithe a chur ar ais, cé gur féidir an t-am a bheith deacair aonair ó thagann na comharthaí go gradamach seachas go tobann.

Seoltóirí refrigirianta atá ann go buan agus pobléimí brú

Nuair a thosaíonn an réfríojén a bhualadh as córas AC, laghdaíonn sé an fhoréacht fhuaraithe go mór. Mura gcloítear na bolganna seo go gasta, tá sé in ann costáil go mór - tá cásanna againne feicthe againne ina gcuailleann na comhbhrúithóirí ar feadh i gcéile. Tugann seomraí a thomhais a sheiceáil go minic léargas mór ar cad é a tharlaíonn taobh istigh den chóras. Tá léitheanna brú gnáth go hiontach, ach nuair a bheidh na huimhreacha ag titim ar feadh ama, is minic a chiallaíonn sé sin go gcaithfidh rud éigin a bheith áitithe. Déanfaidh an-chuid teicneoirí a rá do dhuine ar bith a chluanaíonn leo go minic pointeann na bolganna atuaisce ar fhadhbanna níos mó. Tar éis iliomad tuisceardaithe, is dócha go mbeadh sé worththá a fháil ar véarsaíocht gairmiúla ar an gceist an bhfuil an t-aonad condansaitheoir i gceannas a bheith áitithe in ionad na ceisteanna céanna a réitigh arís agus arís eile.

Guthanna neamhghnácha ó oibríocht an chomhshlósair

Fuaimneacha anaithnid a thagann ón gcineálacht chothaitheora – cosúil le gríobhadh, scraíocht nó na cliceanna iontaofacha – de ghnáth méanach go bhfuil rud éigin ag dul mícheart go meicniúil istigh. Nuair a éisteacht duine leis na fuaimneacha seo, is minic a mheaitseálann siad le cineálacha áirithe briseadh síos, a chuidíonn le bróin a chinneamh go cruinn. Tá sé tábhachtach sonraíocht a scríobh síos faoi na fuaimneacha seo sula mbailíonn duine duine ina chomhair cime, toisc go dteastaíonn sonraíocht ón gcineál seo ó théicníocháin chun a ndualgas a dhéanamh go ceart. Ná hiarracht iad a neamhaird. Níl na fuaimneacha anaithnid sin ann ach fuaimneacha céimniúla; is iad siad an t-éadach dearg a thugann faoi deara go b'fhéidir go mbeidh gá le páirtí a mhalartú go luath sula dtéann na rudaí níos measa agus tá costas airgid níos mó ag teacht orthu san am atá romhainn.

Corrósion amhainneach nó damáiste cothromach coil

Nuair a bhíonn condansóirí amuigh san aer, bíonn corróid ag teacht isteach orthu thar an t-am agus bíonn sé seo ag cur isteach ar an bhfuinneamh a bhaineann siad. Tá sé in inteacht iad a sheiceáil go radhairc régulártha chun fadhbanna a aithint sula dtéann siad dona. Má tá camchuairt ar na cuibhreann copair? Sin comhartha dearg mór. Tá aonaid againne a theip go tapaidh nuair a díthear amháin beagán camchuairt nó corraíocht ar na cuibhreann. Ná húntais a chaitheamh agus iad a sheiceáil láithreach seachas fanacht go dtí go mbeidh an teocht samhraidh ag teacht isteach go trom. Sábháilfidh beartais beaga anois cinniúintí níos mó níos déanaí agus déanfaidh siad cinnte go mbeidh an córas ag rith fuar nuair a bheidh sé tábhachtach.

Trí thuiscint ar na comharthaí rabhaidh seo, is féidir leat cothabháil in am a sholáthar agus an cheann eile a chur in ionad do chondansóir AC, chun saol agus éifeachtacht na cóilseálaíochta aer a shíorú.

Fachtóirí a Luannann Cithrú an Chondansóra

Clogadóint an Chúla ó Bhuidéalacht Chruinnithe

Nuair a thosaightíochtaí, duilleoga agus eile a bheith ag cruinniú timpeall córas aeríochta, bíonn siad ag ceapadh sa spóilíní. Seo chun an sruth aer a bheith blocáilte agus an t-aonad ag obair níos deacra ná mar a bhíodh sé de ghnáth, rud a thagann go minic leis na fadhbanna teochta. Cad é a tharlaíonn ansin? Ní fhanann an t-aonad condaisitheora AC chomh fada agus a bhíodh sé de cheart. Níl an-chuid daoine ag súil le cé chomh tábhachtach atá glanadh ríthábhachtach do na córais acu. Taispeánann staidéir go bhfuil na h-aonaid AC ag rith níos fearr agus ag fhanacht níos faide nuair a bheidh daoine ag déanamh ardúis ar an gcóras go rialta. Is é an t-athbhuail chliste eile smaoineamh a dhéanamh ar na roghanna talcúla ar an taobh amuigh díreach. Féadfaidh plandaíocht shrubhach nó crann ag an gceart a bheith ag cur le níos mó deargaí ag cruinniú ann. Fágáil beagán spáis timpeall an aonaid chun cabhrú leis an fhadhb sin a sheachaint agus chun an córas a choinneáil ag obair go hiontach thar an am.

Onóiríocht an tSalcúir agus Corrós an tSoda

Nuair a bhíonn aonaid AC agamhail leis an gceadhbhá agus go háirithe i gcoirid na dtrá, bíonn na codanna metála acu ag caillfidh go tapa ná mar a bhíodh. Taispeánann taighde go mbíonn na córais aerthachtála atá suiteáilte laistigh de roinnt míle ón mhuir ag dul i bhfeidhm go minic amháin thart ar 60% den t-am a ba chóir leo. Caillfidh an gceadhbhá san aer na comhpháirtí thar am, agus mar sin, an truailliú go luath. Dona daoine a bhfuil feidhm acu ar na coinníollacha seo, is éigean a thabhairt chuig éadromhain neamhcháillí nó príomhchomhpháirtí eile a chosainfidh an t-aimhleacht le haghaidh an fhadtéarmach. Seoithíní na príomhchomhpháirtí seo níos fearr i gcoinne na gcoinníollacha tromchúrsa na farraige agus beidh siad ag sábháil airgid i dtéarmaí athsholáthair anuas an bóthar.

Leibhéil Neamhcheart Torthúcháin na Frigoráin

Tá sé tábhachtach cothú leibhéil na frigoráin cheart chun éifeachtúlacht an chondansóra. Is féidir leis an bpríomhthiomáint nó an t-íos-thiomáint a bheith ina gcomhpháirtí le neamhéifeachtúlacht an tsruthphumpála agus éadóchas móra, ag deireadh thiar a bheith ag an aonad. Is féidir leis an úsáid cheart na meathadóirí a chinntiú leibhéil oiriúnacha frigoráin, ag sábháil toirmisctheacht an tionscail agus ag síorshaothrú trénscríobh an aonaid trí sheirbhísíocht agus monatóireacht rialta.

Stress Viotrálach agus Neamshuimhneachtaí Leictreach

Nuair a bhíonn comhpháirteanna leictreacha ag bualadh thart go leor ón gcrith a thagann uathu féin, bíonn siad ag teastáil, go háirithe nuair a bheidh sé ag teacht le condansóirí. Cabhraíonn seiceáil na nascduithe leictreacha go rialta le problóimí beaga a dhaltaíocht sula dtéann siad i bhfad níos mó. Taispeánann taighde go mbeidh lú le himeacht a dhéanfar ar luchtaithe condansóraí go sábháilte a choinneáil. Tá logaínteach sin mar gheall ar an méid sin tograí sábháilte a chiallaíonn níos lú bualadh don chóras iomlán. Is minic a deirfidh an-chuid teicneoirí do dhuine ar bith a éistear leo go síniúfaidh an tógáil cheart réimse saol an aonaid AC agus go mbeidh sé in ann réiteach go leor de na poblóimí leictreacha a sheachaint a thagann ón gcrith a thagann ó chuidithe a bheith ag bogadh thart istigh.

Tionscadal um Chur Chun Cinn nó Athsholáthar

Anailís chostas ag úsáid an Rialacháin 5,000

Oibríonn an Rialachán 5,000 go hálainn nuair a bhíonn iarracht agat a chinneadh an dtiocfadh ceartú nó cuimhneamh ar chóras HVAC seanmhór. Iarr síos ar aois an tseomra teo-agus-fuilte agus iolraigh an uimhir sin faoi costas an chóirithe. Ansin seiceáil an dtéann an t-iomlán sin thar $5,000. Tugann an-chuid daoine faoi smacht ar an ríomh simplí seo chun cinneadh a dhéanamh faoi a gcórais teochta agus fuilte. Déanann seoltóirí fóill agus teicneoirí HVAC tagairt don ordú seo go minic toisc gur féidir leo breathnú air ag obair am arís is am arís eile leis na daoine ina gcónaí agus na daoine ina mbuailfidh siad an tairbhe as a gcostais. Is é an rud is léir anseo ná éalú ó na cásanna ina mbuailfidh daoine airgid aríst agus aríst ar chórais shonracha aonair, ach ansin a bheith ag dul i bpéireadh níos mó sula mbeidh siad ag briseadh níos minice ar an gceann tamaillte.

Idirdhealú idir aois agus éifeachtúlacht i n-aonaid shiúlach

Tendliúnaíonn córais aertháthaithe atá thart arna chloí cheana féin go dtí an méid is gá, rud a chiallaíonn tuilleadh airgid ar do chuntas leictreachais ag deireadh an mhíosa. Níl na huimhreacha agam freisin nuair a breathnaítear ar chórais a bhfuil níos mó ná 15 bliain orthu cheana féin. De ghnáth, bíonn costas airgid níos mó ag dul i bhfeidhm chun iad a choinneáil ag rith toisc go n-itheann siad go leor leictreachais agus go briseann siad síos go minic. Caithfidh daoine a gcónaí a bheith ag breathnú go cúramach ar an éifeacht a bhíonn ag na haonaid seo sine ar a gcuisle. Nuair a bhíonn daoine ag cur na n-aonad sin a bhfuil aois orthu in ionad, is minic a bhíonn a gcumas feidhme agus í lú níos mó ar a gcumas ón lá céanna, chomh maith le costais níos ísle ar úsáid na gceart ag deireadh gach mhíosa. Seoithín, bíonn costas tosaigh ar chóras nua, ach aimsíonn an chuid is mó den phobal go gcuirfidh an laghdú ar chailleamh fuinnimh an t-airgead sin ar ais go tapaidh in ionad é a chaitheamh go minic ar dearcadh ar an gcóras seanfhairsinge a bhfuil aois mhór orthu agus nach mian leis an saol a bheith ag dul i bhfeidhm.

Meastóirí comhshuí ar leithéidí an réfrigirint

Nuair a bheidh tú ag smaoineamh ar réitigh i gcomparáid le hionchur in aonad tithíochta, bíonn gá le haghaidh seictheanna comhshaoil go cinnte. Tá go leor códanna sine fós agus siombailí cosúil le R22 nó Freon ann a raibh cosc leo mar a d'iarbhrigh siad ar an gcomhshaol. Tacaíonn na hairíonna seo le laghdú an ozain agus le heiteanna gháis teasa. Tá sochair a bheith ag imeacht chuig siombailí nua-aimseartha agus tá airgead freisin sa rud sin ós rud é go mbíonn spreagair ag rialtais chun teicneolaíocht glas a úsáid. Leis na rialacha níos strictí a bheidh ag teacht i bhfeidhm ar fud an tíre maidir le cad is féidir leat a úsáid mar shiombail, tá níos mó daoine ag tosú ar aonaid ionchuir a oibríonn le siombailí a gceadaithe mar R-410A nó fiú an chur chuige nua-aimseartha R-454B. Cabhraíonn an t-athrú seo leis an bhplanéad a chosaint, ach tá sé freisin ag rá go mbeidh an t-ionad tithíochta ag freastal ar chodanna reatha agus go mbeidh sé in ann díolacháin a sheachaint sa todhchaí ós rud é an t-úsáid a bheidh déanta aige ar mhairearials aonair.

Straitéisí Oibritheachais chun Saol an Chumhaidhcheora a Shíniú

Minicíocht Ghlanúcháin Choilgne

Déanann bobailí glan AC a bheith ag dul i gcrích nuair a bhíonn sé ag dul faoi pherformance maith a fháil ó do chóras agus é a fháil fadó. Nuair a bhíonn bruslach ag cruinniú ar na bobailí sin, cuireann sé cosc ar an mballteacht bheith ag imeacht agus déanann sé an córas iomlán obair níos mó ná is gá, ag caillteáint leictreachais sa phróiseas. Molann an-chuid teicneoirí iad a ghlantóireacht go hiondúil gach trí nó sé mhí, go háirithe má tá an t-aonad seachtrach faoi bhun crann agus duillí ag titim nó gar do shuíomhanna tógála faraonra ag suí. Téann an gcóras cosantóireachta ríthábhachtach seo chun comhtharchur a chur ar an sruthadóireacht aer agus é a chur stop le brú neamhshuí ar chomhpháirtí. An toradh? Fionghalú níos fearr ar fud an tighe agus níos lú briseadh amach gan bheith sáithte sa tsruth.

Páistí Seicthearna Póifisiúla

Is dócha gur é seirbhísí proifisiúnta rialta an bealach is fearr chun fadhbanna le comhshóirí AC a aimsiú sula dtéann siad i bhfadhbanna móra don tseisiúnaí. Déantar i rith na seicthe seo breathnú ar na leibhéil frithshuíocháin agus scanáil na gcomhpháirteanna chun a bheith ag amhail le haghaidh wear and tear nach mbeadh a fhios ag daoine chun breathnú ar aonaid seachtracha. Is é a dhéanann na bisitithe seo luachmhar ná go leanann siad na treandanna feidhmíochta ar feadh an ama, rud a chuidíonn leo fadhbanna beaga a aithint sula dtéann siad i bhreis agus i gcoistí. Molann an-chuid mhaith saoráidí HVAC seirbhísí iomlána seo a dhéanamh amháin sa bhliain ar a laghad. Cuidíonn an choincheap seo de réir a chéile le haghaidh cothabháil chun saothcháin a shásaigh níos faide agus chun iad a choinneáil ag rith go héifeachtach trath nuair a thagann na míonna samhraidh agus tá an-tiomantas airge ar chumhacht.

Tiomantaí i gcoinne Milleadh Comhshaoil

Is minic a fhaigheann sé seo a bheith coiteann maidir leis an gcóras a chosaint ón ngalarú a thagann ón timpeallacht. Nuair nach bhfuil an córas i úsáid, is fearr a bheith agamsa leis na cosáin a choinneáil chun an t-aonad a chosaint ón sneachta an geimhreadh agus ón bhfán an samhradh a d'fhéadfadh aon damáiste a dhéanamh. Tá sé seo chomh maith leis na roghanna a dhéanann anonn leis an ngortáil - is fearr a bheith agamsa leis an uisce a bheith ag rith amach ón áit a bhfuil an condenser suite chun an streis a sheachaint ar an ngearrthóg. Taispeánann na taighdeanna an t-ábhar a bhfuil ann sa saol fíorúil nuair a choinneáiltear cosaint dílis ar an gcóras. Cad é an toradh? Oibríonn na condensers níos fearr le himeacht an ama, mar a bheith agam leis an rud a chuirfidh an nádúr i gcrích.

Meadhairtí Athsholáthair Páirteach

Meaitseáil chondansóirí nua le cumas an chóras

Nuair a chuirtear cóndansóir AC in ionad ní mór é a chomhaireamh go dian leis an méid a fhéadfaidh an córas a sheoladh. Má tá an tonnáiste mícheart agat, thosaíonn na rudaí ag dul go dond go tapaidh. B'fhéidir go gcuirfidh an córas i bhfeidhm gearr nó ní bheidh sé in ann an t-áit go leor fuarú, rud a chaillfidh leictreachas agus a chuirfidh brú mó ar gach rud. Tógann an cineál seo fadhbanna suas ar an gceist leictreachais agus caillfidh na páirteanna níos tapaidh ná a bheadh gá. Mar sin, tá sé ina chiall le obair le heochairí teoic agus fhuaróidh a bhfuil taithí acu. Ríomhann siad go beacht cad is gá don spás agus molann siad aonaid a mheaitseálann leis na sonraí sin. Má déantar é go ceart, tá éifeachtacht níos fearr ann don iomlán agus níos lú na scillte teochta neamhsháraithe san áit.

Seasmhacht shaintréithe an tionscailteoir teicneolaíochta

Tá sé seo thar a bheith tábhachtach gur cuireadh an condansóir AC nua i bhfeidhm ag duine a thig leis an gceart a dhéanamh, mar sin é a chur in áit ag duine a bhfuil eol agam air an difríocht a dhéanann. Tuismitheoirí a bhfuil teastais orthu an rud a thuigfidh siad cad is gá a dhéanamh de réir na dtreoracha saoil agus an tsoltaíocht, ag cabhrú le himeacht míchuí a chosc a d'fhéadfadh sonraíocht a chur in éag an lá éigin amach anseo. É a iarraidh go minic ó tháirgtheoirí na n-eachmhuirneachtaí freisin an t-evidiúint go raibh an t-eagrú déanta ag duine cáinteach sula gcuirfidh siad i bhfeidhm na sonraíochta. Ní hamháin go simplí faoi scéalanna a chomhlíonadh é seo ag obair le haghleogaí a bhfuil teastais orthu - cuireann sé cosaint in aghaidh na gceann trom a thagann amach as an gceann eile agus é ag cosaint an gharáin freisin nuair a thagann trioblóidí amach ina dhiaidh sin.

Éagaíocht ar chóipthe agus ar chóipthe a bhfuil ardú orthu

Nuair a bhíonn tú ag breathnú ar shainimh chomhpháirteanna, is é a fhéachaint ar na sonraíthí garáinste a dhéanann gach difríocht i ndecisiún mhúinte a dhéanamh. Tá téarmaí garáinste ag éagsú go mór idir brandanna éagsúla, mar sin is féidir an branda mícheart a roghnú a bheith ina ghealltanas breise síos an bóthar mar a bhíonn na córais ag aois. Tá roinnt cuideachtaí ann a chuirfidh isteach garáinste fadaí dona haghaidh na n-aghaidheanna éifeachtacha fuinnimh, is féidir sin a bheith ina thartúlach más mian le duine rud a fháil a choinneoidh sé níos faide. Tógann sé am chun na garáinste seo a chur i gcomparáid chun inspéisín a fháil ar cad é atá is fearr. Cabhraíonn sé le pointeáil daoine i dtreo na gcomhpháirteanna a oibríonn go maith ach a choinneoidh siad úsáid rialta thar na blianta.

Ceisteanna Coitianta

Cé hé seo a chríochnaíonn AC condenser de ghnáth?

Is é 12 go 15 bliain an t-am a chríochnaíonn condensers AC, ag brath ar phatrúin úsáide agus ar chleachtadh coiscéime.

Cad iad na comharthaí go mbeidh condenser AC agam ag teastáil aistrithe?

Is iad na comharthaí eile craoladh fuaraithe laghdaithe, caillteanais leanúnacha frithgháis, guthanna neamhghnách ón oibríocht, agus corpúlacht amhail is coil leoithne.

Conas an t-am a chríochnaíonn condenser AC a shíorú?

Cothabháil rialta cosúil le páraíocht a ghlanadh, iniúchtaí gairmiúla agus cosaint in aghaidh maiseanna timpeallachta is iad na stratégaithe éifeachtacha.

Cad ba cheart dom smaointe nuair a bheidhim ag cinneadh an bhfuil ceart agam condansóir AC a chur in ionad?

Sé sinneáil chomh maith leis an 5,000 Riail chun costas a anailísiú, breis agus éigeandóireacht aois, agus éifeacht timpeallachta cineálacha frigoráin.

Clár na nÁbhar

- Tipiciúil Comhdhlúthadán AC Ionchais Shaolré

- Comharthaí Eagraíochta Go Teastaíonn Cuir I gcéill Duit Do Chondansóir AC

- Fachtóirí a Luannann Cithrú an Chondansóra

- Tionscadal um Chur Chun Cinn nó Athsholáthar

- Straitéisí Oibritheachais chun Saol an Chumhaidhcheora a Shíniú

- Meadhairtí Athsholáthair Páirteach

- Ceisteanna Coitianta