টার্বো ইন্টারকুলার

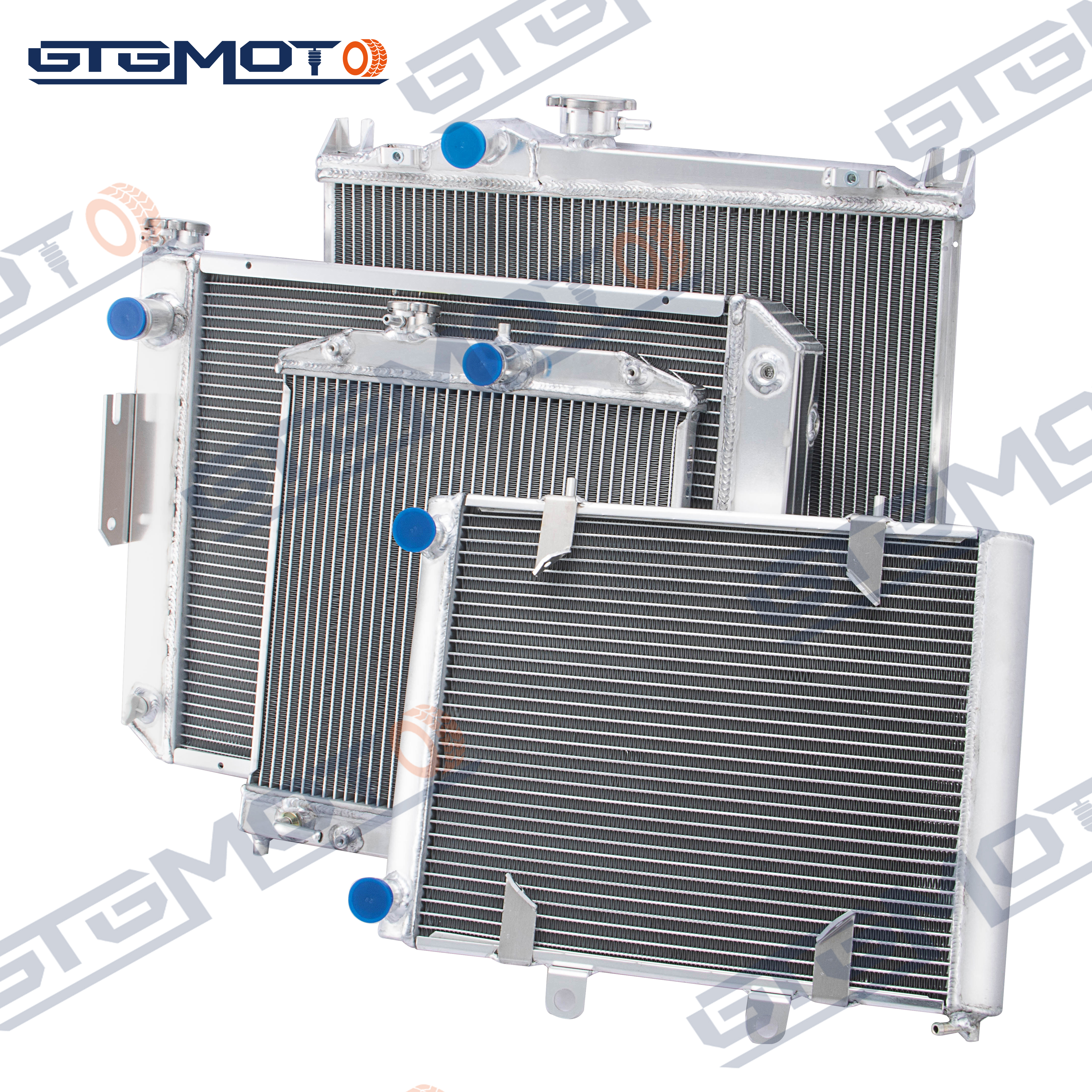

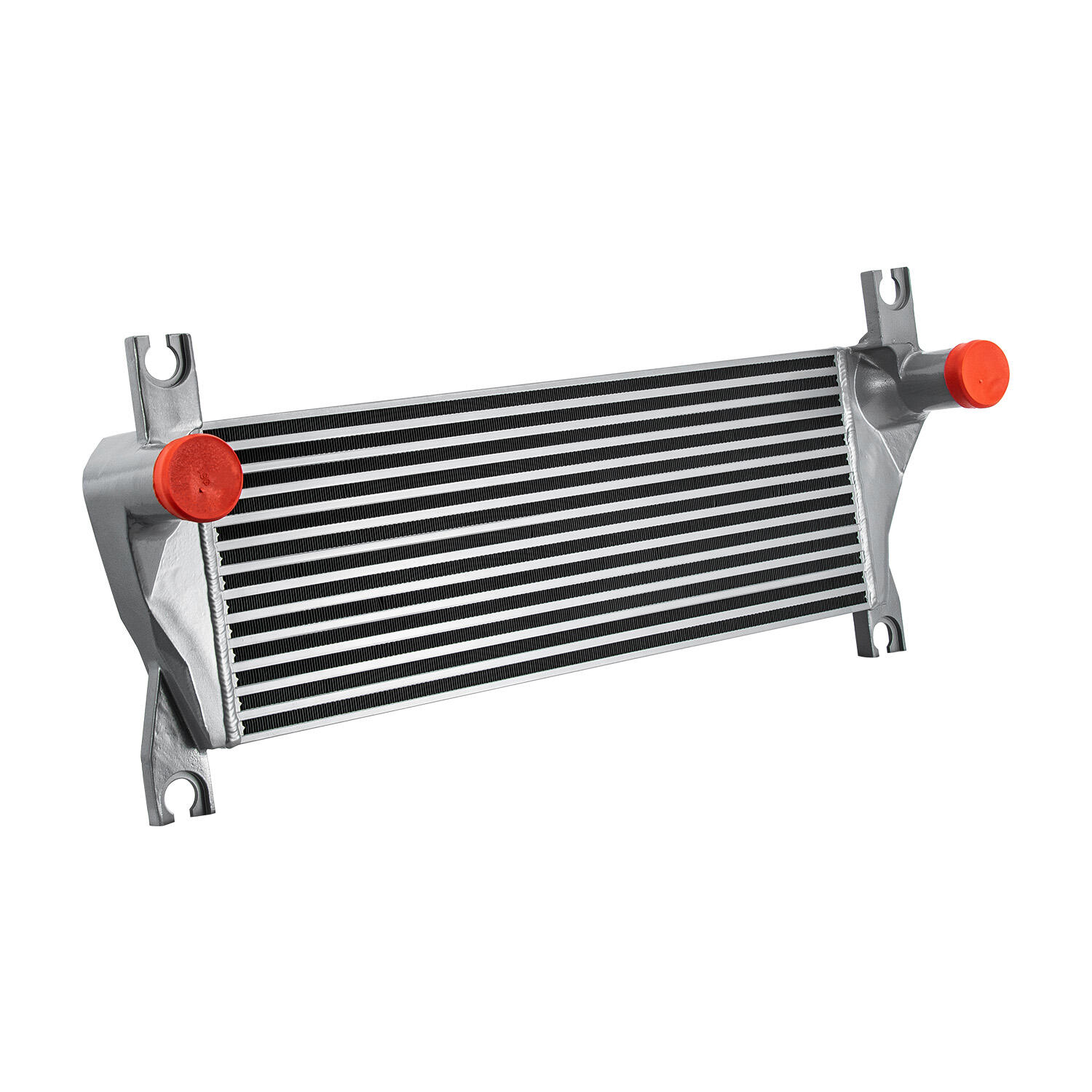

টার্বো ইন্টারকুলার হল টার্বোচার্জড ইঞ্জিনের একটি গুরুত্বপূর্ণ উপাদান যা পারফরম্যান্স এবং কার্যকারিতা সামগ্রিকভাবে বাড়িয়ে তোলে। এই উন্নত শীতলক পদ্ধতি টার্বোচার্জার থেকে আসা চাপিত বায়ুর তাপমাত্রা কমাতে ডিজাইন করা হয় যাতে তা ইঞ্জিনের জ্বালানি ঘরে ঢুকার আগে ঠাণ্ডা হয়। যখন টার্বোচার্জার বায়ু চাপিত করে, তখন তা গরম হয়ে যায়, যা তার ঘনত্ব এবং অক্সিজেনের পরিমাণ কমিয়ে দেয়। ইন্টারকুলার এই সমস্যার সমাধান করে চাপিত বায়ুকে ঠাণ্ডা করে, যা তাকে আরও ঘন এবং অক্সিজেন-শীর্ষক করে। এই ঠাণ্ডা এবং ঘন বায়ু জ্বালানি কম্বাস্ট করার জন্য আরও কার্যকর করে যা ফলে ইঞ্জিনের শক্তি বাড়ানো এবং জ্বালানির ব্যবহার উন্নত করা হয়। আধুনিক টার্বো ইন্টারকুলার উন্নত হিট এক্সচেঞ্জার প্রযুক্তি ব্যবহার করে, সাধারণত এলুমিনিয়াম নির্মিত হয় এবং সঠিকভাবে ইঞ্জিনিয়ারিংযুক্ত ফিন এবং চ্যানেল রয়েছে যা তাপ ছাড়ার মাত্রা বাড়িয়ে তোলে। এগুলি হতে পারে এয়ার-টু-এয়ার সিস্টেম, যা পরিবেশ বায়ু ব্যবহার করে শীতল করে, অথবা এয়ার-টু-ওয়াটার সিস্টেম, যা তরল শীতলক ব্যবহার করে। ইন্টারকুলারের স্থাপনা বায়ু প্রবাহ ও চাপ হারানো কমাতে রणনীতিগতভাবে নির্ধারিত হয়, সাধারণত রেডিয়েটরের সামনে বা ইঞ্জিন বে এর বিশেষ স্থানে। এই গুরুত্বপূর্ণ উপাদানটি উচ্চ পারফরম্যান্সের গাড়ি, বাণিজ্যিক ট্রাক এবং বিভিন্ন শিল্প অ্যাপ্লিকেশনে ব্যবহৃত হয় যেখানে ইঞ্জিনের কার্যকারিতা এবং শক্তি আউটপুট সর্বোচ্চ করা প্রয়োজন।