Understanding the Overflow Tank's Role in Engine Cooling Systems

Pressure Regulation and Thermal Stability

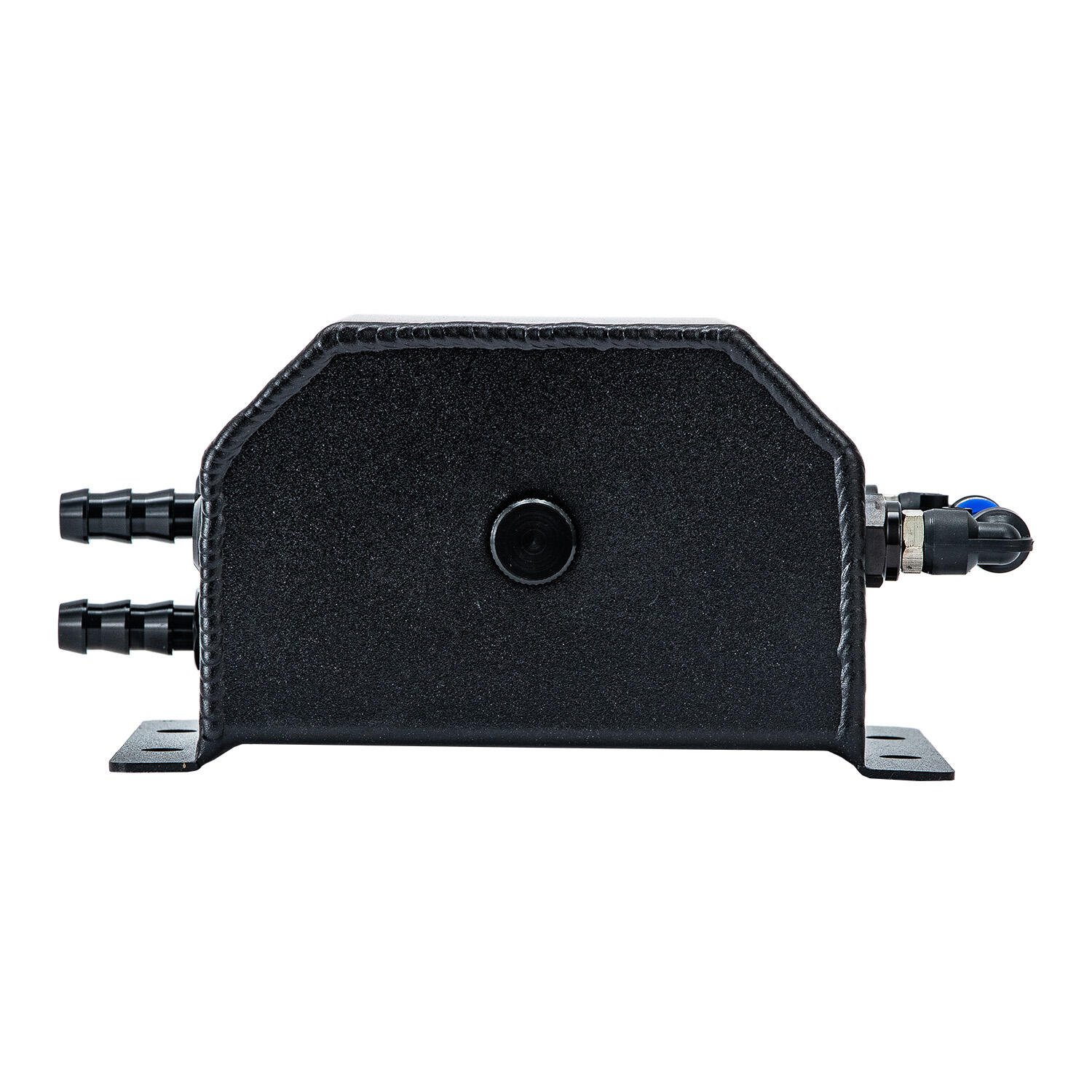

The overflow tank is really important for keeping pressure levels stable in the engine cooling system. Think of it as acting like a pressure relief valve that stops everything from getting out of whack so no parts get stressed beyond their limits. Research has shown these pressure control mechanisms actually improve how well the engine handles heat, meaning less wear on moving parts and better overall performance. When coolant pressure stays regulated properly, engines tend to run at just the right temperatures most of the time. This consistent operation makes all the difference when it comes to how long the engine lasts and how efficiently it performs day after day.

Managing Coolant Expansion and Contraction

The overflow tank plays a crucial role in handling coolant expansion, stopping unwanted spills when the engine heats up. When temps go up, coolant expands naturally, and the overflow tank acts as storage space for all that extra fluid before it can spill out. Once the engine cools down again, the stored coolant flows back into the system through special valves. This prevents those pesky air pockets from forming inside the radiator which would mess up proper circulation. Mechanics have seen time and again that engines with properly functioning overflow tanks run smoother through both hot summer days and cold winter mornings. Keeping the cooling system ready for whatever comes next means fewer breakdowns on the road or at work sites where downtime costs money.

Preventing Air Ingress in Closed Systems

Overflow tanks do more than just store excess coolant they actually stop air from getting into the system, something that can create vapor lock problems and mess up how well the engine cools down. When air gets inside, it basically blocks proper coolant circulation, leading to overheating situations that might seriously harm the engine components. Most mechanics will tell car owners to check those tank seals regularly because even small cracks or loose fittings let air sneak in, causing all sorts of headaches later on. Looking at the overflow tank during routine maintenance makes sense too since catching minor issues early means better cooling performance overall. Taking care of this part isn't just good practice it saves money in the long run by keeping engines running smoothly without unexpected breakdowns.

How an Overflow Tank Works: The Coolant Cycle Explained

Cold Engine State: Initial Coolant Levels

When an engine is cold, the overflow tank actually does something pretty important - it keeps coolant levels where they need to be so the engine stays protected right from startup. Without enough coolant circulating, certain parts of the engine get way too hot, which can lead to all sorts of trouble down the road. Take this scenario: if coolant levels drop below what's needed, those critical engine components aren't getting covered properly anymore. That means the engine runs hotter than normal, and eventually needs expensive repairs. According to various automotive research findings, drivers who ignore coolant levels when starting their vehicles often end up dealing with major engine issues later on. So keeping coolant at proper levels isn't just about warm engines either; it matters a lot even when everything is still cool.

Heat Expansion Phase: Storing Excess Coolant

When an engine runs and coolant starts getting warm, expansion happens naturally. The overflow tank comes into play here by holding onto extra coolant as temperatures rise, keeping everything balanced in the cooling system. Without proper storage capacity, engines would overheat pretty quickly. That's why these tanks are so important for maintaining stable operation under normal conditions. A well functioning overflow tank actually shields critical engine parts from damage, especially when vehicles are pushed hard on long trips or in hot weather situations where stress on mechanical systems increases dramatically.

Coolant Return During Temperature Drop

As engines cool down after running hot, the overflow tank plays a key role in sending coolant back into the main system. This keeps things balanced and helps the engine run better overall. The whole system works together to make sure everything runs smoothly, which actually saves on fuel costs too because the cooling system functions properly. Mechanics know from experience that keeping an eye on how coolant flows back into the system matters a lot for longevity. Without this return flow, air bubbles can form inside the cooling passages. These air pockets create problems because they block proper coolant circulation, leading to overheating issues and potential damage over time. That's why regular maintenance checks are so important for vehicle owners who want their engines to last longer.

Impact of Overflow Tank Performance on Engine Temperature

Heat Dissipation Efficiency

When an overflow tank works properly, it helps get rid of excess heat, something really important for keeping engines running at their best. Research into car cooling systems shows that cars with good maintenance on their overflow tanks tend to run cooler overall. The drop in temperature means the engine runs smoother without so much stress on all those metal parts inside. Less stress equals fewer breakdowns down the road, so the engine lasts longer and stays dependable for years instead of just months.

Maintaining Optimal Coolant Volume

Overflow tanks play a big role in keeping coolant volumes at their best level, something that affects how well engines stay cool during operation. When there isn't enough coolant circulating through the system, engines tend to overheat pretty quickly, sometimes causing serious damage to internal components. Mechanics often recommend checking coolant levels at least once every month or two as part of routine vehicle care. According to recent studies from automotive repair associations across North America, vehicles with properly maintained coolant systems typically see around 8-10% better fuel economy compared to those with neglected systems. Plus, these cars generally last longer before needing major repairs. So don't forget to look under the hood occasionally and ensure both the overflow tank and main coolant reservoir are filled correctly for continued engine reliability and performance down the road.

Effects of Pressure Imbalances

When there's uneven pressure inside a car's cooling system, it really messes with how well the engine stays at the right temperature. That's where the overflow tank comes in handy. It helps absorb those pressure swings so everything runs smoother for the engine. Mechanics see this all the time actually cars with bad pressure problems tend to eat through parts faster than normal. The radiator hoses get brittle quicker, water pumps fail sooner, and sometimes even the head gasket gives way. Keeping that overflow tank working properly isn't just about avoiding breakdowns either. A functioning tank means the engine lasts longer between major repairs and performs better day after day without unexpected surprises.

Consequences of a Faulty Overflow Tank

Overheating Risks from Coolant Loss

Overflow tanks that aren't working right can really mess up a car, mainly because they let coolant escape. If this tank doesn't do its job storing and sending back coolant as it should, then there's going to be serious coolant loss over time. What happens next? The engine starts getting too hot, which is one of the main reasons engines pack it in early. Mechanics see plenty of cases where cars lose coolant and end up with overheating problems. Regular checks on the overflow tank matter a lot for keeping things running smoothly. Making sure this part stays functional helps stop those pesky overheating incidents before they happen and keeps the engine healthy for longer periods between repairs.

Pressure Spikes and Component Stress

When an overflow tank starts acting up, it creates pressure spikes inside the car's cooling system which puts serious strain on important engine parts. The fluctuating pressure often leads to blown gaskets or warped cylinder heads, both of which mean expensive trips to the mechanic. Mechanics see this all the time when they're working under hoods. A good functioning overflow tank keeps pressure levels steady throughout the system. That kind of stability matters because constant pressure changes wear down components gradually until something gives way completely. Regular checks and maintenance on the overflow tank make sense for anyone wanting to keep their engine running smoothly longer without unexpected breakdowns costing thousands later on.

Air Pockets Reducing Cooling Capacity

When an overflow tank isn't working right, it lets air bubbles form inside the cooling system, which really cuts down on how well it cools things off. Air in the system messes with heat moving through properly, so engines run hotter than they should and this can lead to serious problems down the road. Overflow tanks actually play a pretty important part in keeping those pesky air pockets from forming while making sure everything stays cool enough. Mechanics across the board will tell anyone who listens that regular checks and maintenance for overflow tanks are worth their weight in gold. Keeping this component in good shape means better heat management overall and fewer chances of running into trouble with overheating issues, something every car owner wants to avoid.

Overflow Tank Maintenance Best Practices

Visual Inspection for Cracks/Leaks

Checking the overflow tank regularly for any cracks or leaks is really important if we want it to keep working properly. Most mechanics will tell us that catching these problems before they get bad saves money in the long run. Some studies show that finding small leaks early on can actually double how long the whole cooling system lasts. When there are cracks or leaks present, the tank just cant do its job right managing those coolant levels which leads to all sorts of headaches including engine overheating. So spending a few minutes every now and then looking at this part makes sense for anyone who wants their car running reliably without unexpected breakdowns.

Coolant Level Monitoring Techniques

Keeping an eye on coolant levels matters a lot if we want our engines running smoothly and avoiding those nasty overheating situations. Most folks use either a dipstick test or some kind of float gauge to get a good read on what's going on inside the system. Both methods work pretty well when done correctly. Mechanics generally suggest checking these levels at least once a month during normal maintenance routines. Regular attention to this simple task helps maintain proper cooling function across the board, which cuts down significantly on potential engine problems down the road.

When to Replace Critical Components

Replacing key parts like the overflow tank at the right time keeps the whole system working properly. Look out for telltale signs during routine inspections corrosion spots, cracks, or any physical damage that signals it's time for a new part. Mechanics know from experience that putting off these replacements often leads to bigger problems down the road in the cooling system. A small investment now prevents expensive repairs later on. Engines tend to run smoother and last longer when maintenance follows this kind of proactive approach rather than waiting until something breaks completely.

Overflow Tank vs. Expansion Tank: Key Differences

Pressure System Variations

Knowing how pressure works differently in overflow versus expansion tanks matters a lot when maintaining vehicles properly. Overflow tanks generally run at much lower pressures than expansion tanks, and this affects where they go and what they do. The distinction really counts. Automotive guides stress that getting these two mixed up can lead to serious problems down the road. Overflow tanks usually have those special caps that let them manage extra steam and coolant without building up too much pressure. Expansion tanks work differently though they keep pressure going all the time, sending coolant back into the engine whenever it needs topping off during operation.

Coolant Circulation Mechanisms

Overflow and expansion tanks work quite differently when it comes to circulating coolant, which affects how well the engine stays cool. Expansion tanks let the heated coolant come back into the system after expanding, while overflow tanks just sit there holding extra fluid until needed again. Because of this design difference, expansion tanks keep running at better efficiency since they constantly move coolant throughout the entire system without letting it stagnate. Mechanics who've worked on various vehicles know this matters a lot for fine-tuning performance under different conditions. What really sets expansion tanks apart though is their ability to handle those pressure spikes that happen during hard acceleration or climbing hills. Sure, they're more complicated to install and maintain compared to simple overflow setups, but for cars that need maximum cooling capacity like race cars or heavy duty trucks, the extra complexity pays off in terms of reliability and temperature control.

Application-Specific Design Features

Overflow and expansion tank designs change depending on what they need to do in cars. Some engines need special features because of their particular demands. Take high performance engines for example they often require stronger systems to handle their workload. From what we've seen in practice, when tank design matches up well with engine specs, everything works better. Getting this right means vehicle cooling actually works as intended, which explains why picking the correct tank matters so much for different car models. Knowing how these tanks differ isn't just academic knowledge it makes all the difference between a cooling system that works reliably day after day versus one that fails unexpectedly.

FAQs: Overflow Tanks and Cooling Performance

Signs of Overflow Tank Failure

Knowing when an overflow tank is failing matters a lot for keeping engines running properly. Look out for things like coolant dripping from the tank or levels going up and down unexpectedly. Tanks that develop cracks tend to leak pretty badly and make the whole cooling system work harder than it should. Mechanics always tell their customers to catch these problems before they get too bad because fixing them early saves money and headaches later on. According to actual repair shop records, cars where owners acted quickly at first signs of trouble had far fewer major engine failures compared to those ignored until something broke completely.

Impact on Fuel Efficiency

A well working overflow tank makes a big difference in how good a car gets on gas. When coolant stays at the right level, engines don't have to work so hard, which means better miles per gallon according to what mechanics see day to day. Keeping coolant topped up stops the engine from getting too hot, so it runs smoother and burns less fuel overall. Most drivers probably don't think much about their overflow tanks until there's a problem, but regular checks can actually help keep the car running better for longer and save money at the pump in the long run.

Compatibility with Different Coolant Types

Different overflow tanks work better with specific coolants, so picking the right one really matters for how well the whole system functions. Coolant makers warn that getting the formulation wrong can actually wear down the tank material over time, eventually causing leaks or worse, complete failure. When folks take the time to check coolant compatibility, they're helping their systems run smoother for longer periods. This attention to detail keeps the cooling system performing at its best and adds years to the life of the vehicle without unnecessary headaches down the road.

Table of Contents

- Understanding the Overflow Tank's Role in Engine Cooling Systems

- How an Overflow Tank Works: The Coolant Cycle Explained

- Impact of Overflow Tank Performance on Engine Temperature

- Consequences of a Faulty Overflow Tank

- Overflow Tank Maintenance Best Practices

- Overflow Tank vs. Expansion Tank: Key Differences

- FAQs: Overflow Tanks and Cooling Performance