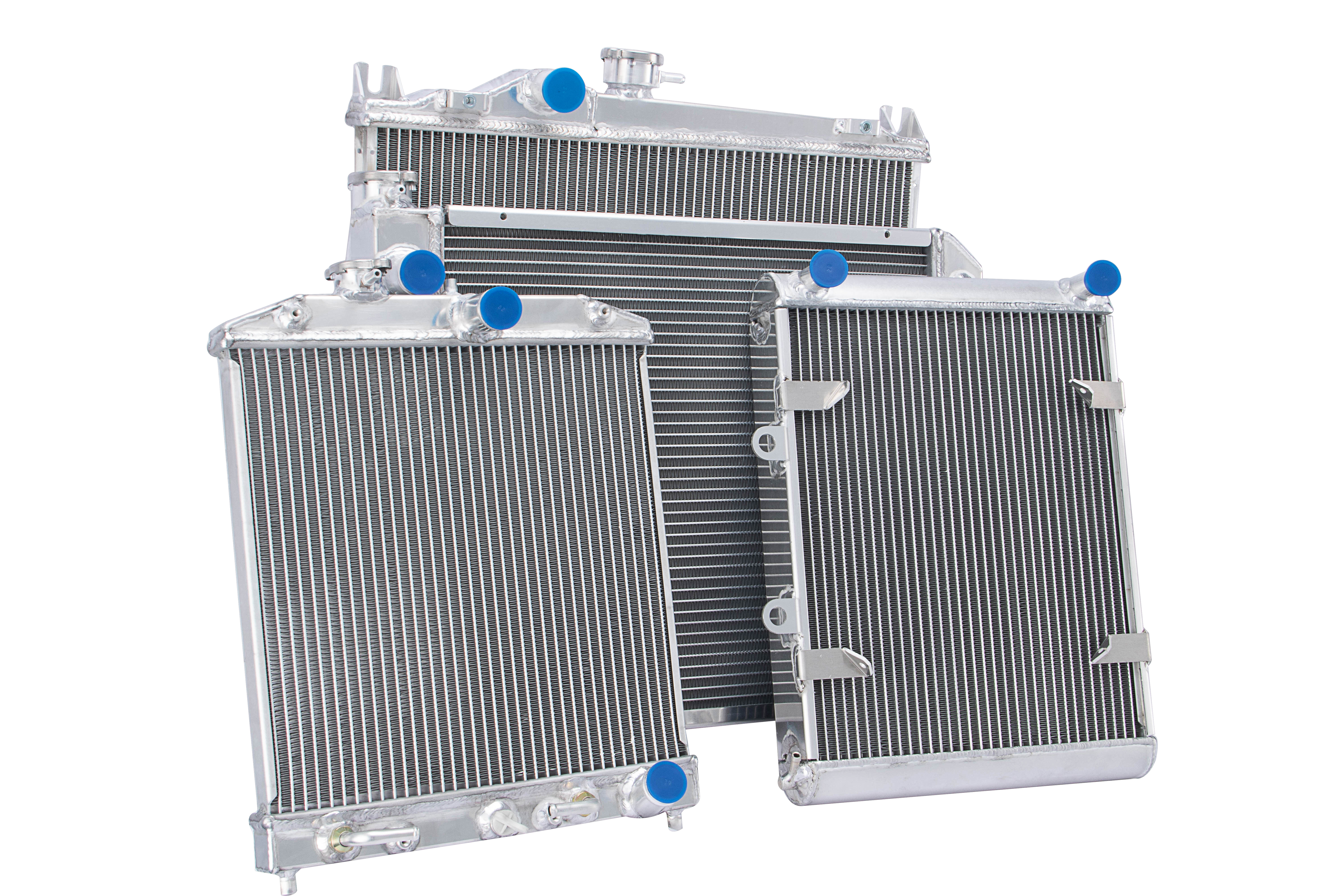

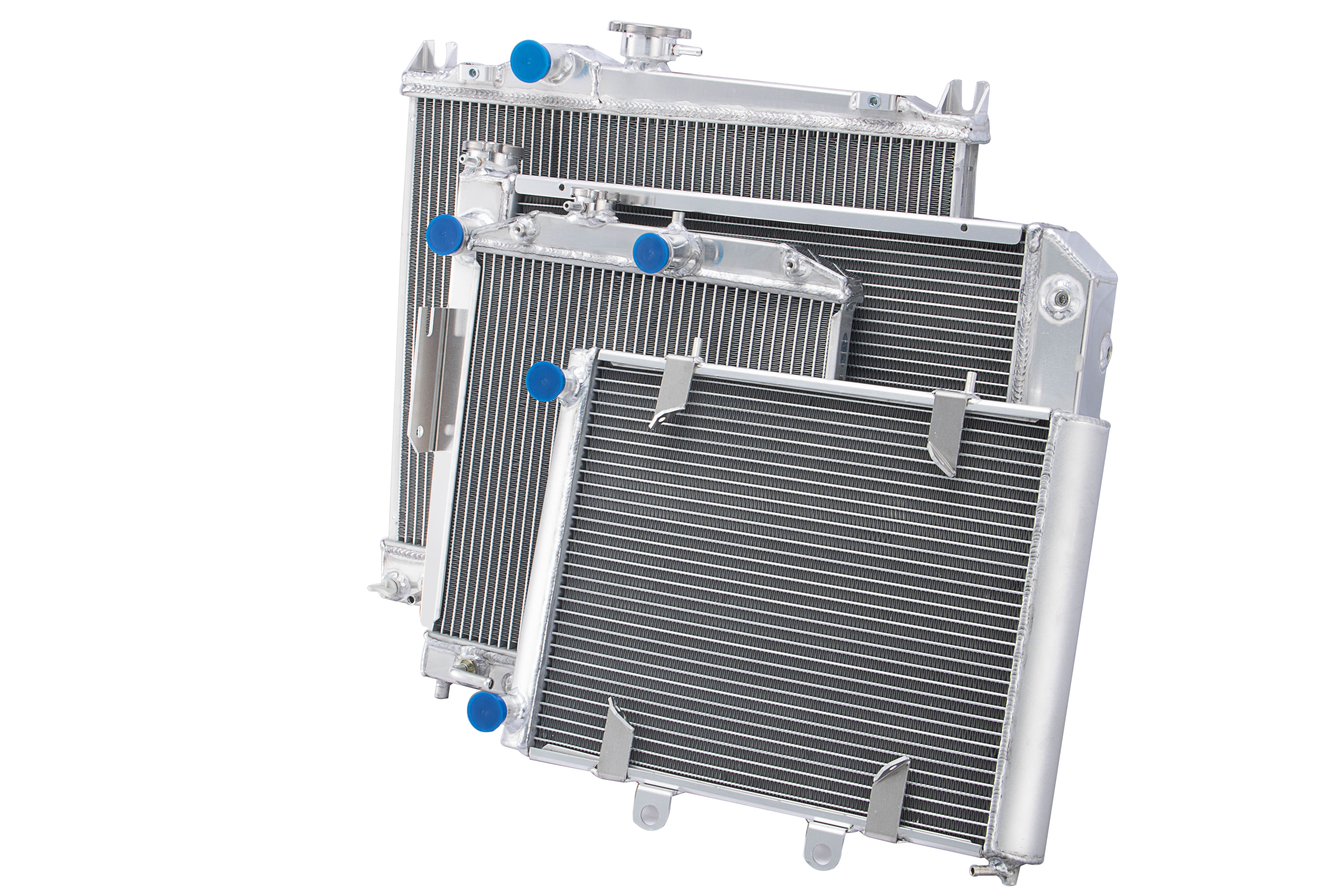

radiator factory

A radiator factory represents a state-of-the-art manufacturing facility dedicated to producing high-quality heating and cooling solutions for various applications. The facility encompasses multiple production lines equipped with advanced automation systems, precision welding equipment, and quality control stations. These factories utilize cutting-edge technology including robotic assembly systems, automated testing facilities, and computer-controlled manufacturing processes to ensure consistent product quality. The main functions include the fabrication of core components, assembly of radiator units, pressure testing, and finishing processes. The factory employs sophisticated brazing techniques and advanced metallurgical processes to create durable, efficient heat exchange systems. Quality control measures are implemented at every stage, from raw material inspection to final product testing, ensuring each radiator meets strict performance and safety standards. The facility also maintains research and development capabilities to innovate new designs and improve existing products. The factory serves diverse markets including automotive, industrial, residential heating, and commercial HVAC systems, producing both custom and standardized radiator solutions to meet varying customer requirements.