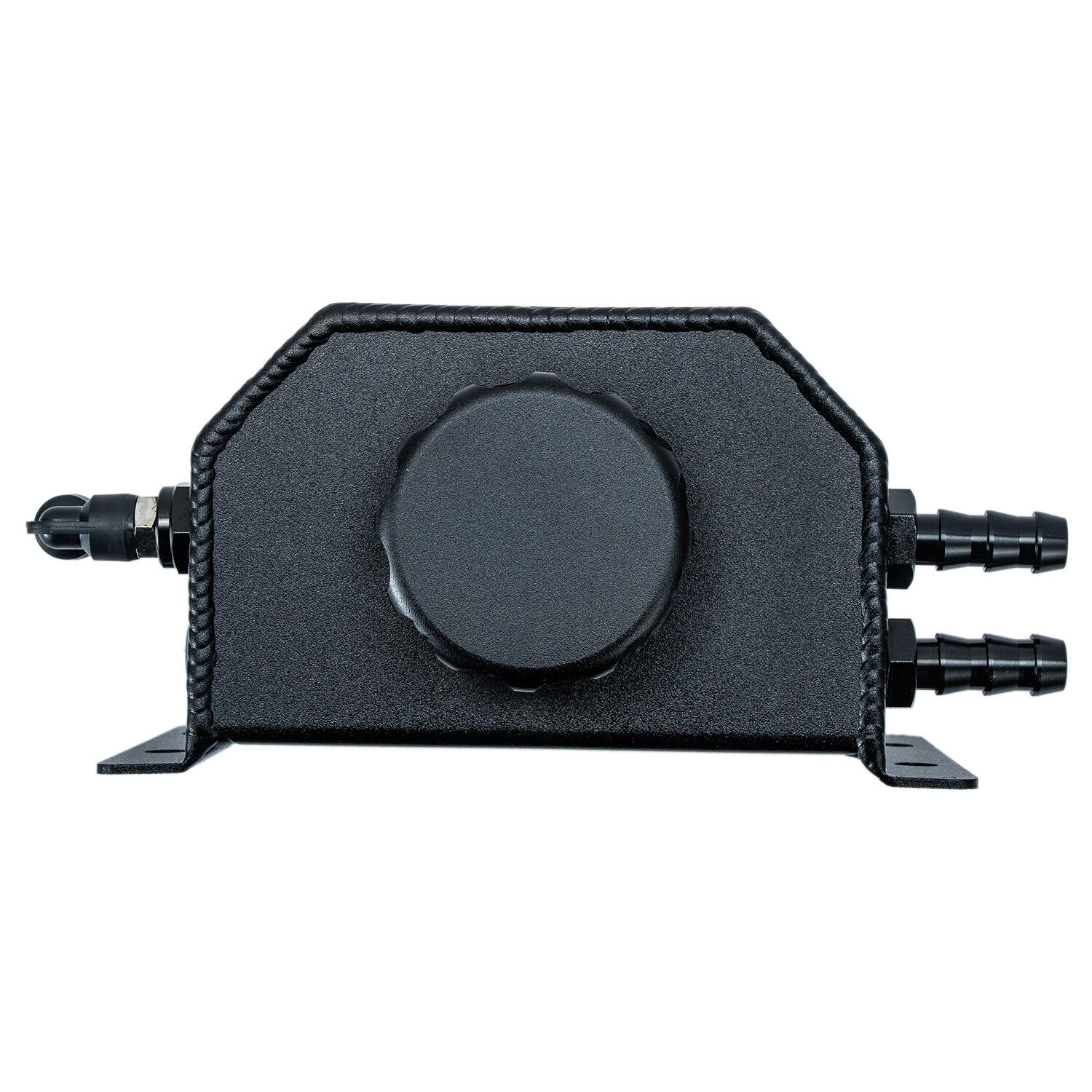

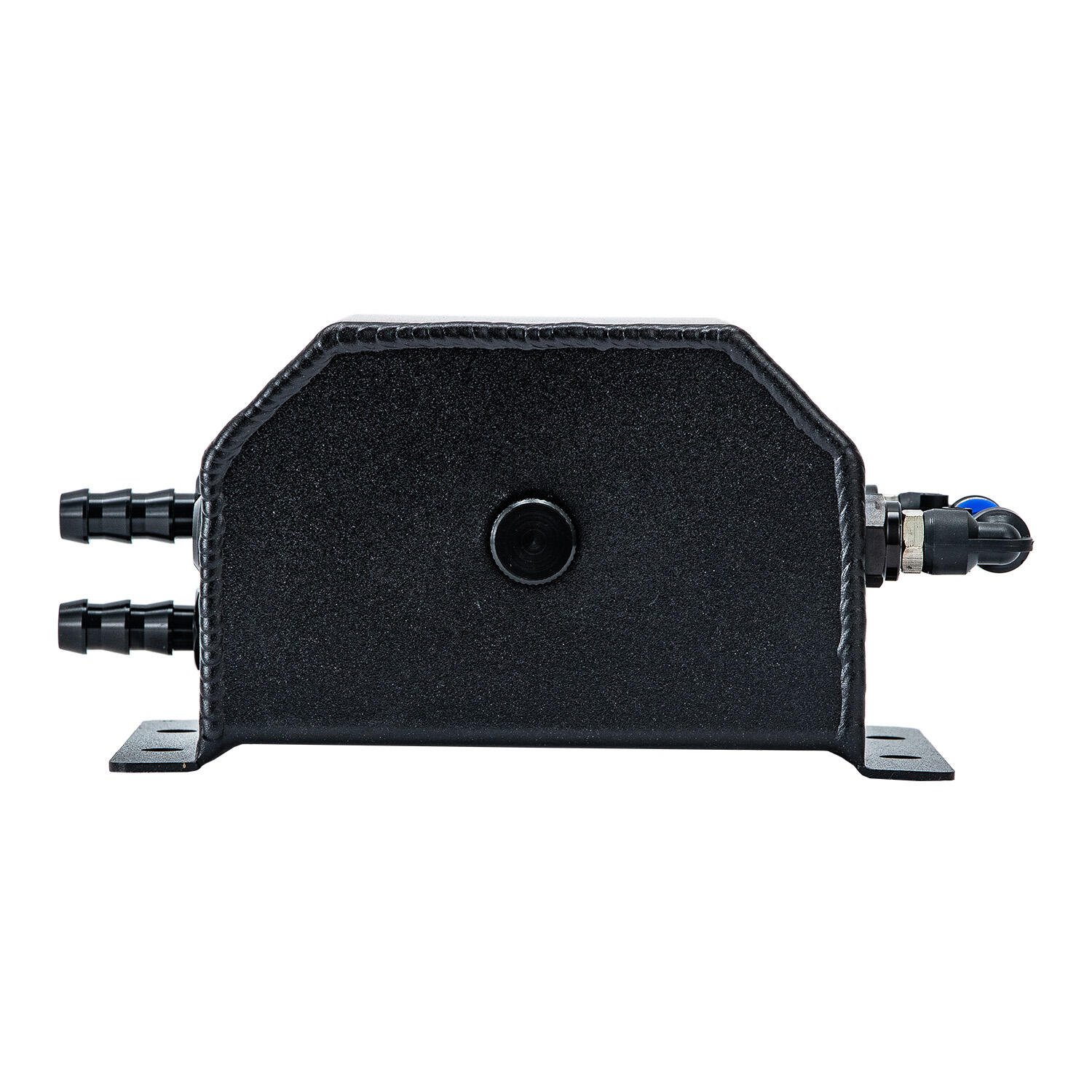

over flow tanks

Overflow tanks are essential components in fluid management systems, designed to handle excess liquid and maintain optimal operational levels in various industrial applications. These specialized vessels serve as a safeguard against system overflow, preventing potential damage and ensuring continuous operation. The tanks incorporate advanced level monitoring systems and automated control mechanisms to regulate fluid levels effectively. They are typically constructed from durable materials such as stainless steel or reinforced plastics, capable of withstanding various environmental conditions and chemical exposure. The design includes strategically placed inlet and outlet ports, along with sophisticated venting systems to maintain proper pressure levels. Modern overflow tanks feature integrated sensors that provide real-time monitoring of fluid levels, temperature, and pressure, enabling precise control and preventive maintenance. These tanks are crucial in numerous industries, including manufacturing, chemical processing, water treatment, and automotive applications, where they help maintain system efficiency and prevent costly downtime. The technology behind overflow tanks continues to evolve, with newer models incorporating smart monitoring capabilities and enhanced safety features to meet increasingly stringent industrial standards.