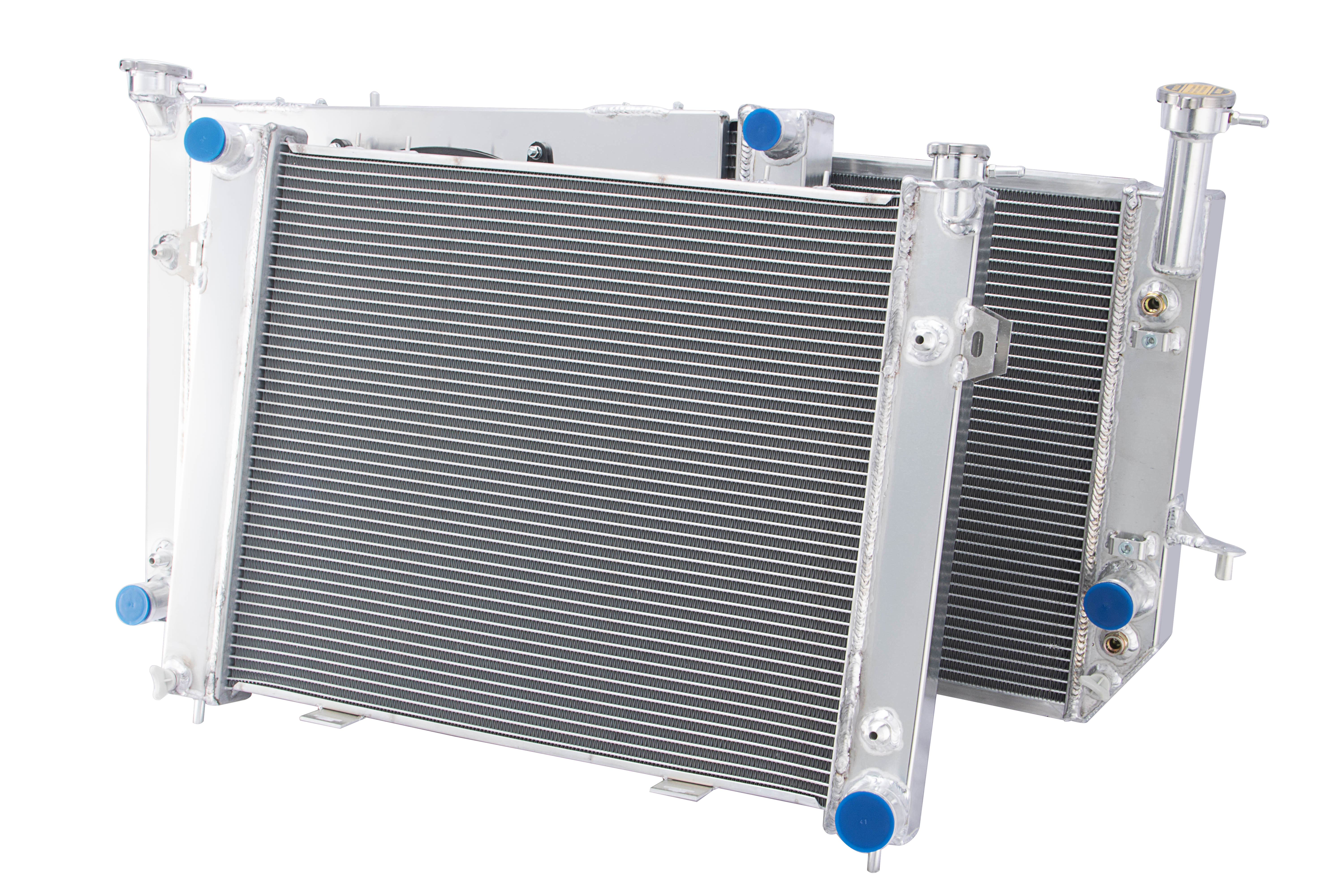

intercooler tube

An intercooler tube is a critical component in turbocharged engine systems, serving as a vital conduit for compressed air between the turbocharger and the intercooler. This specialized tube is engineered to handle high-pressure airflow while maintaining optimal temperature control. The primary function of an intercooler tube is to transport compressed air from the turbocharger to the intercooler, where it's cooled before entering the engine's intake manifold. Constructed from durable materials such as aluminum or reinforced silicone, these tubes are designed to withstand extreme temperatures and pressure variations while maintaining structural integrity. The tubes feature precisely calculated diameters and wall thicknesses to ensure efficient airflow and minimal pressure drop. Modern intercooler tubes often incorporate advanced design elements like mandrel bending to maintain consistent internal diameter throughout curves, preventing airflow restrictions. They are equipped with high-quality couplers and clamps to ensure airtight connections, preventing boost leaks that could compromise engine performance. In performance applications, these tubes may also feature internal surface treatments to reduce friction and improve airflow characteristics. The installation of intercooler tubes requires careful consideration of routing to minimize heat exposure and maximize cooling efficiency. These components play a crucial role in the overall performance and reliability of turbocharged engines, making them essential for both stock and modified applications.