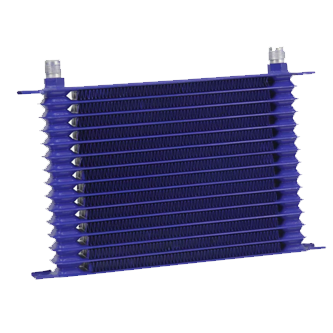

cross country intercoolers

Cross country intercoolers are essential performance components designed to enhance engine efficiency and power output in turbocharged vehicles. These sophisticated cooling systems work by reducing the temperature of compressed air from the turbocharger before it enters the engine's combustion chamber. By lowering the intake air temperature, cross country intercoolers increase air density, allowing for more oxygen to be packed into each cylinder, resulting in more efficient combustion and increased horsepower. The design incorporates advanced heat exchange technology, featuring precisely engineered fins and tubes that maximize cooling surface area while minimizing airflow restriction. Modern cross country intercoolers utilize high-grade aluminum construction, offering superior heat dissipation properties while maintaining lightweight characteristics. These units are specifically engineered to withstand the demanding conditions of cross-country driving, including varied temperatures, altitudes, and weather conditions. The system's core is typically mounted in a position that optimizes airflow, usually in front of the radiator or in specialized side-mount configurations, depending on the vehicle's design and requirements. Advanced end tank designs ensure uniform air distribution across the core, preventing hot spots and maintaining consistent cooling performance.