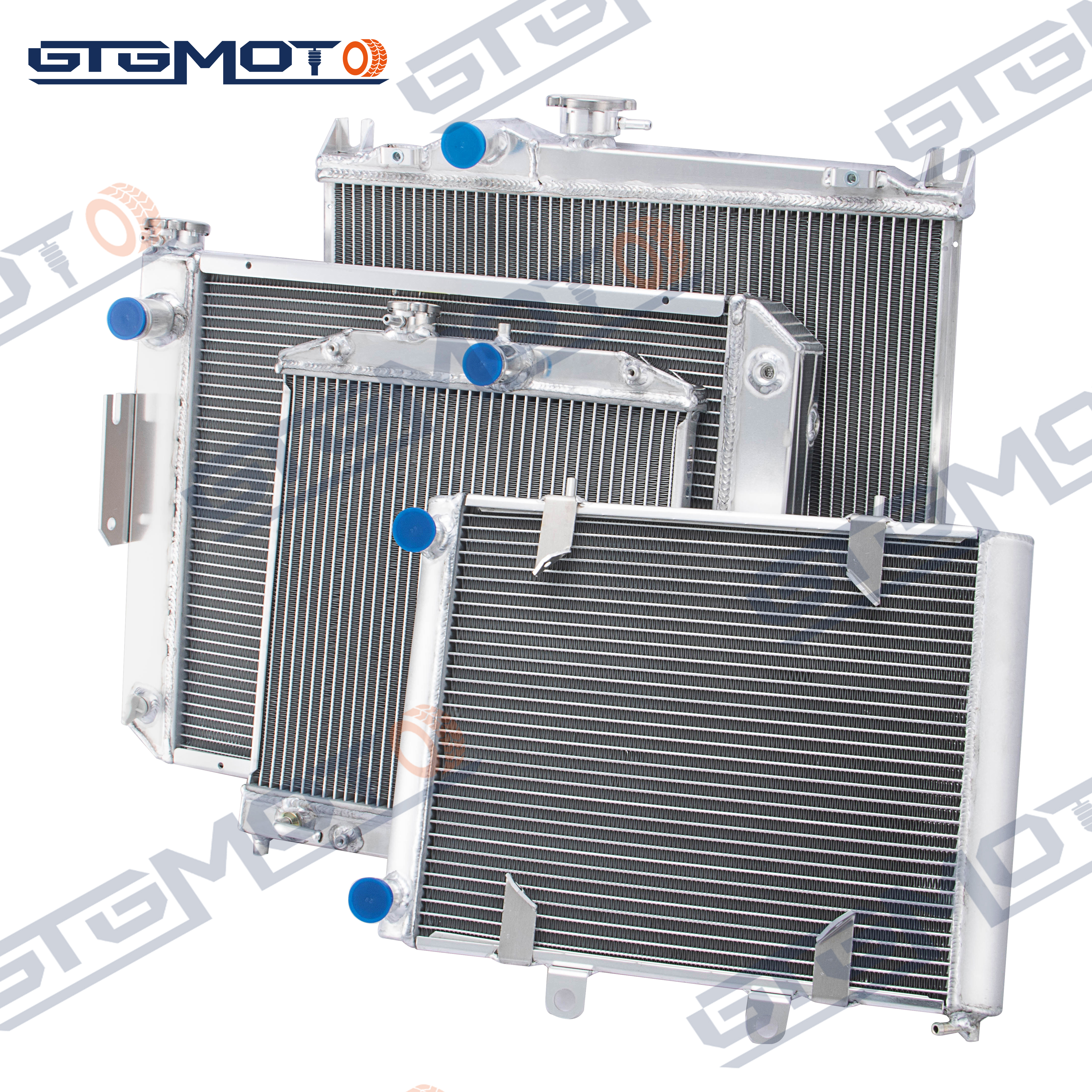

air intercooler

An air intercooler is a vital component in forced induction systems, designed to enhance engine performance and efficiency. This heat exchanger effectively reduces the temperature of compressed air from the turbocharger or supercharger before it enters the engine's combustion chamber. By cooling the incoming air charge, the intercooler increases air density, allowing more oxygen molecules to enter the engine, resulting in improved combustion efficiency and increased power output. Modern air intercoolers utilize advanced aluminum construction with precisely engineered fins and tubes to maximize heat transfer efficiency. The design typically incorporates strategically placed inlet and outlet ports to ensure optimal airflow distribution. These systems can be either air-to-air or air-to-water configurations, each offering specific advantages depending on the application. Air intercoolers are commonly found in high-performance vehicles, commercial trucks, and industrial applications where forced induction is employed. The technology has evolved significantly, with contemporary designs featuring computer-optimized flow patterns and thermal management capabilities that contribute to better overall system performance and reliability.