Wat is die funksie van 'n AC-kondensor in 'n motor se lugversorgingstelsel?

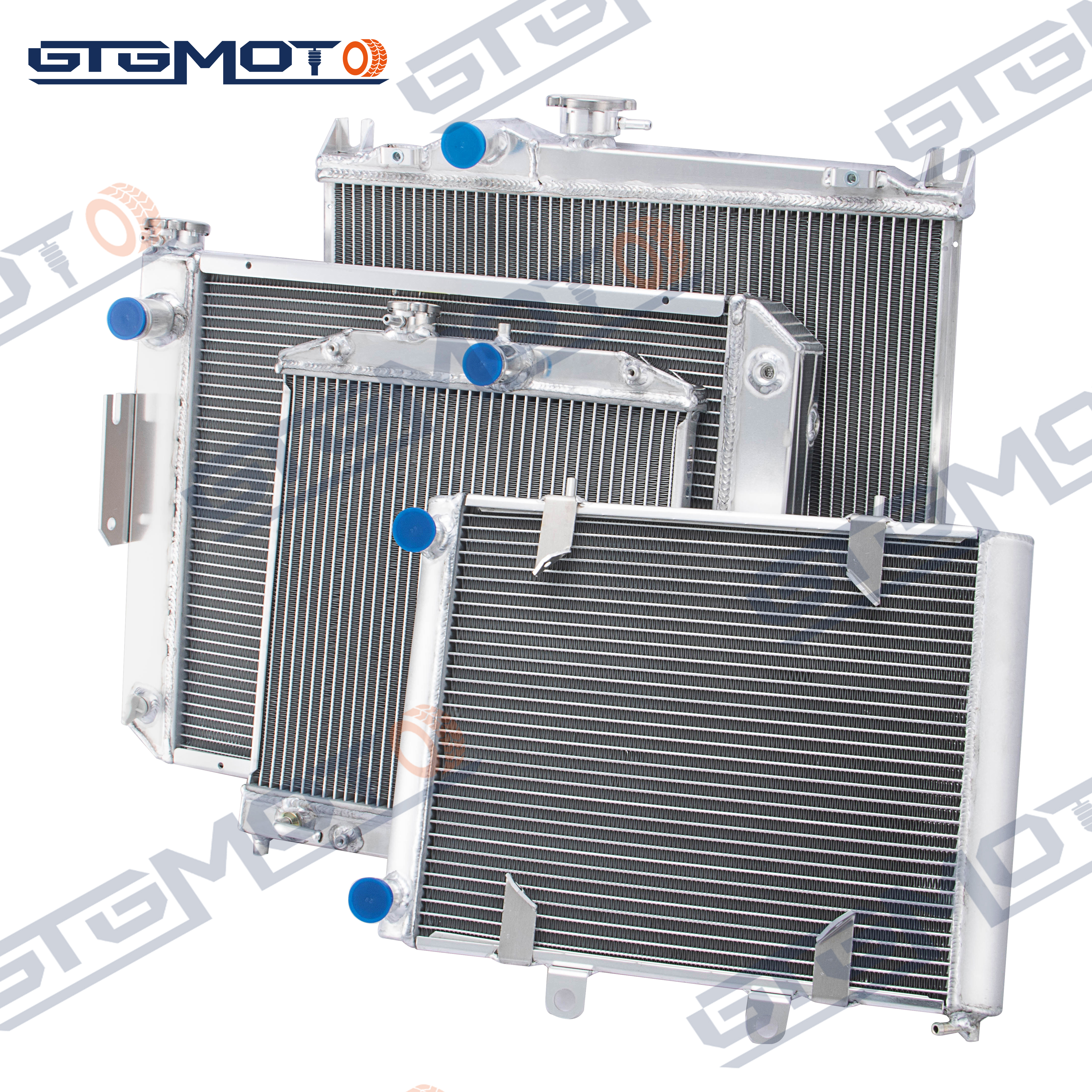

Die klimaatbeheer-verdiggingsmasjien van jou motor speel 'n kritieke rol in jou koelemiddel. Dit werk as 'n hitte-uitruiler wat warm koolstofgas in vloeistof omskakel. Hierdie proses is die kern van die klimaatbeheer-verdiggingsfunksie en verseker dat koue lug na jou kajuit vloei. Wit...

MEER BEKYK